Forming process suitable for thermoplasticity elastic body extrusion blow molding

A technology of thermoplastic elastomer and molding process, which is applied in the field of molding technology, adhesive material and thermoplastic elastomer co-extrusion blown film molding technology, which can solve the problems of unsuitability, narrow processing temperature range, serious frictional heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

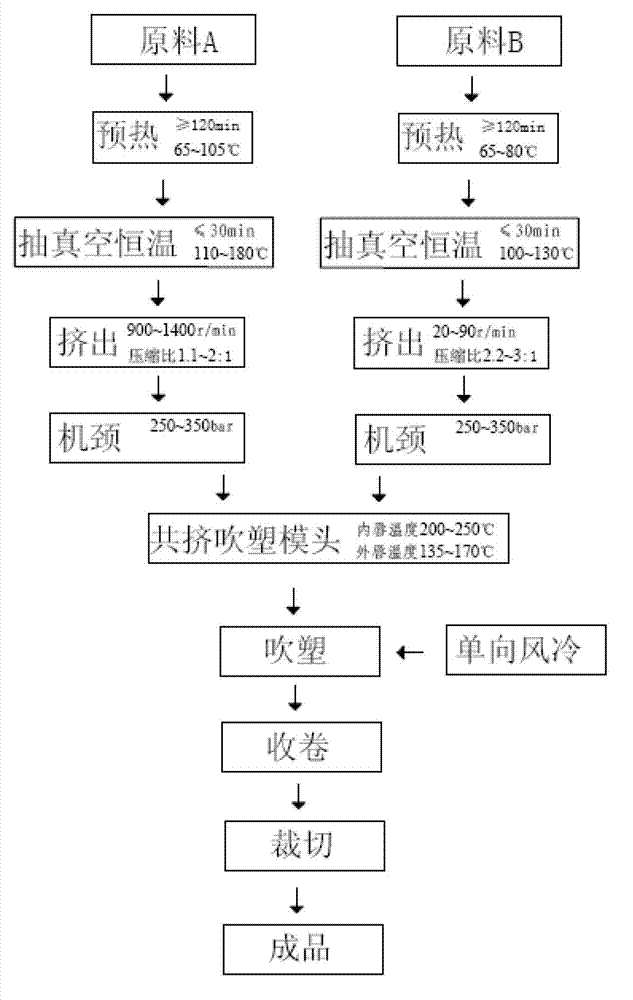

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0033] The invention relates to a molding process suitable for extrusion blow molding of thermoplastic elastomers and a molding process of co-extrusion blow molding of adhesive materials and thermoplastic elasticity.

[0034] The raw material involved in the former process is raw material A, namely thermoplastic elastomer, and the raw material involved in the latter process involves raw material B in addition to raw material A, namely adhesive material, a rubber modified body with adhesive properties. Here, raw material A is a thermoplastic elastomer containing a continuous phase of polyamide and a dispersed phase of at least partially vulcanized rubber, obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com