Longitudinal edge folding and ironing-seaming method and mechanism of packaging bag

A packaging bag, longitudinal technology, applied in the field of automatic bag making method and bag making equipment, can solve the problems of easy torn, torn, poor bonding strength, poor quality, etc., achieve good quality and prolong service life , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

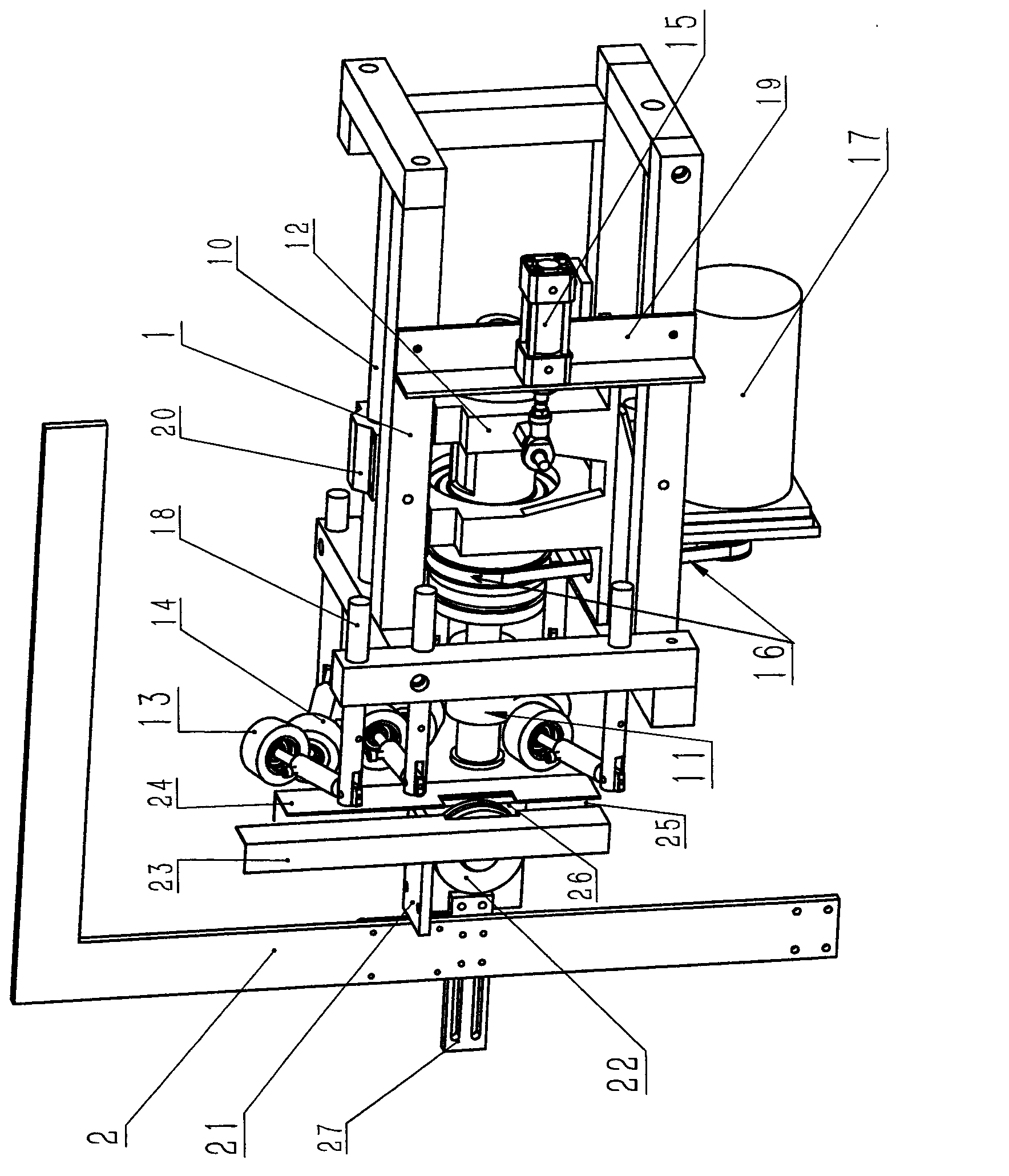

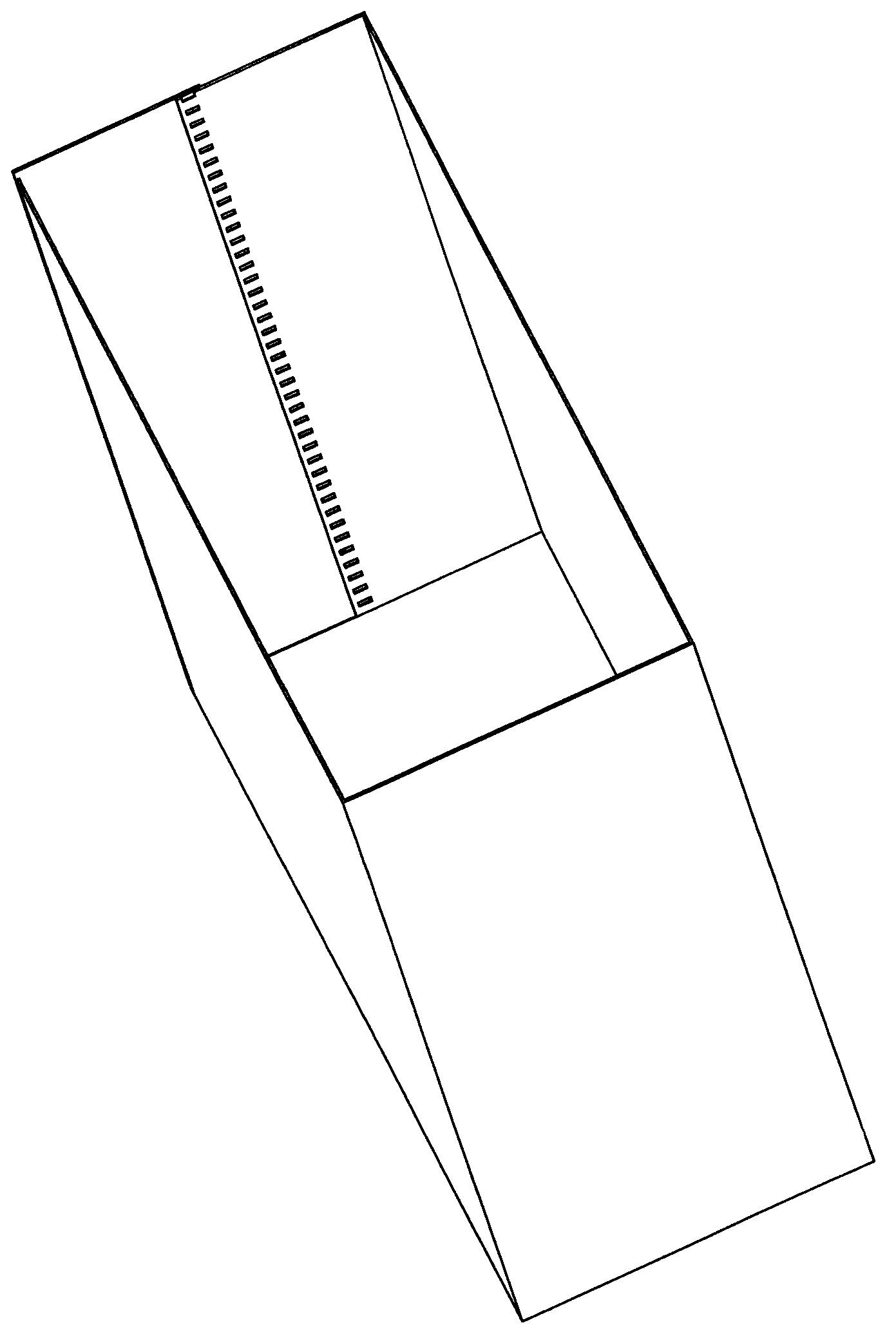

[0011] refer to figure 1 It can be seen that the longitudinal folding and ironing method of the packaging bag of the present invention is: first, after the (non-woven fabric) bag material is conveyed through (folding) crimping, its left vertical bag side material enters the left folding plate and the right folding mouth along the left folding mouth plate The gap 25 of the board is pressed by the left folding roller and slides downwards, and the right longitudinal bag side material also slides down along the right folding board and is pressed by the right folding roller; then, the left and right When the vertical bag edge material slides, it also drives the ironing pressure wheel to roll. At this time, the ironing head of the ironing device (ultrasonic type) faces the left and right vertical bag edge material on the ironing pressure wheel that overlaps up and down. Folding and ironing treatment, and the ironing head rotates while ironing to make the bag material slide down smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com