Rock wool waste residue plate and preparation method thereof

A technology of rock wool waste residue and rock wool is applied in the field of rock wool board and its preparation, which can solve the problems of high processing cost, landfill occupation, etc., and achieve the effect of good thermal insulation effect and good economic and social value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Proportion: The mass ratio of rock wool waste slag to rock wool resin glue is 3:2; the mass ratio of rock wool waste slag to waterproofing agent is 15:4. Weigh each raw material.

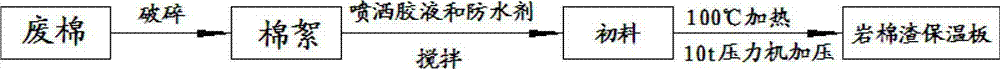

[0014] Put the weighed rock wool slag into the crusher and break it into cotton wool with a length of 1~5cm, then spray the weighed rock wool resin glue and waterproof agent on the cotton wool, and then stir it with a mixer at 1500 rpm for 2 After 10 minutes, spread the mixed primary material on the formwork, and press it with a 10t hot press at 100°C for 5 minutes to form a rock wool waste slag board.

Embodiment 2

[0016] Proportion: The mass ratio of rock wool waste slag to rock wool resin glue is 6:1; the mass ratio of rock wool waste slag to waterproofing agent is 15:1. Weigh each raw material.

[0017] Put the weighed rock wool slag into the crusher and break it into cotton wool with a length of 1~5cm, then spray the weighed rock wool resin glue and waterproof agent on the cotton wool, and then stir it with a mixer at 1500 rpm for 2 After 10 minutes, spread the stirred raw material on the formwork, and press it with a 10t hot press at 100°C for 3 minutes to form a rock wool waste slag board.

Embodiment 3

[0019] Proportion: The mass ratio of rock wool waste slag to rock wool resin glue is 4:1; the mass ratio of rock wool waste slag to waterproofing agent is 5:1. Weigh each raw material.

[0020] Put the weighed rock wool slag into the crusher and break it into cotton wool with a length of 1~5cm, then spray the weighed rock wool resin glue and waterproof agent on the cotton wool, and then stir it with a mixer at 1500 rpm for 2 After 10 minutes, spread the stirred raw material on the formwork, and press it with a 10t hot press at 100°C for 4 minutes to form a rock wool waste slag board.

[0021] The rock wool waste slag boards in the above three embodiments are hot-pressed to produce rock wool waste slag boards with a length of 1220 mm and a width of 600 mm. Its appearance dimensions are measured: length and width deviations are less than ±2.0mm, thickness has no negative deviation, positive deviation is less than 2.0mm, diagonal deviation is less than 3.0mm, side straightness de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com