Isolated fireproof heat insulation plate and manufacturing process thereof

A fire-proof insulation board, isolation technology, applied in the direction of heat preservation, fire prevention, building components, etc., can solve the problems of failing to meet the requirements of A-level, less sources, poor thermal performance, etc. Good work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

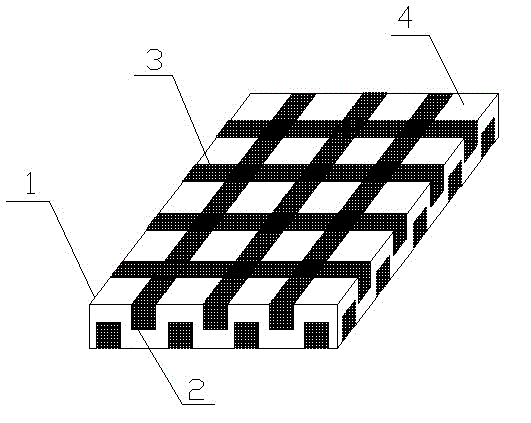

[0032] Such as figure 1 As shown, the isolated fireproof insulation board of the present invention includes a B-grade material insulation board body 1, the insulation board body 1 is a whole, and its upper and lower sides are processed with longitudinal and horizontal linear grooves 2, and the upper and lower sides of the board body are 4 longitudinal grooves and The lower longitudinal grooves are arranged in dislocation, and the 4 horizontal grooves on the top of the board are arranged in dislocation with the lower horizontal grooves. A grade material is arranged in the groove 2 to form a fire isolation belt 3; the depth of the groove 2 is equal to or greater than that of the insulation board. One-half of the thickness between the upper and lower sides; the upper and lower sides of the insulation board and the four sides are provided with a class A material bonded fire protection layer; the A class material bonded fire protection layer is equipped with reinforcing materials su...

Embodiment 2

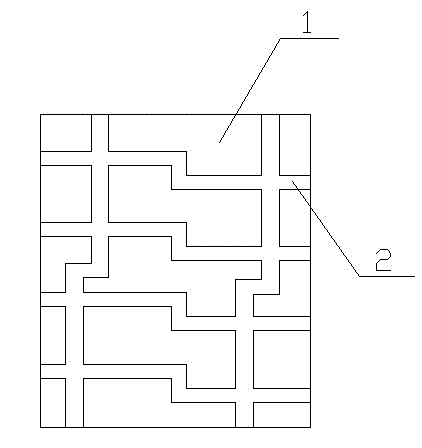

[0043] Such as figure 2 As shown, in the isolated fire-proof insulation board of the present invention, the upper and lower sides of the insulation board body 1 are processed with longitudinal and transverse fold line grooves 2, and the rest of the structure is the same as that of embodiment 1.

[0044] The manufacturing process of the isolation type fireproof insulation board is the same as that of embodiment 1, except for the processing of folded line grooves in steps a and c.

[0045] According to GB8624-1997, test the flame retardancy and smoke density level (SDR) of the isolated fireproof insulation board of this example, and the combustion performance of this sample meets the requirements of GB8624-1997 standard A level.

Embodiment 3

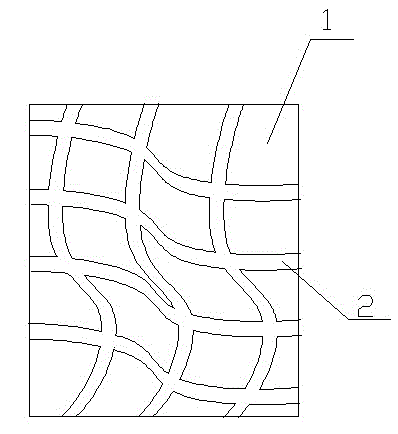

[0047] Such as image 3 As shown, in the isolated type fireproof insulation board of the present invention, the upper and lower sides of the insulation board body 1 are processed with longitudinal and transverse curved grooves 2, and the rest of the structure is the same as in embodiment 1.

[0048] The manufacturing process of the isolation type fireproof insulation board is the same as that of embodiment 1, except that the curved grooves are processed in steps a and c.

[0049] According to GB8624-1997, test the flame retardancy and smoke density level (SDR) of the isolated fireproof insulation board of this example, and the combustion performance of this sample meets the requirements of GB8624-1997 standard A level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com