Spray header and chemical vapor deposition equipment

A spray head and gas technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of uncontrollable gas distribution, and achieve the goal of avoiding different deposition rates, good deposition effect, and uniform deposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It can be seen from the content recorded in the background art that the shower head of the prior art has the problem of uncontrollable gas distribution. The core idea of the present invention is that, by introducing at least one partition plate, the shower head is divided into multiple areas, so that the zoned control of the gas can be realized, and the airflow field that can meet the demand can be obtained.

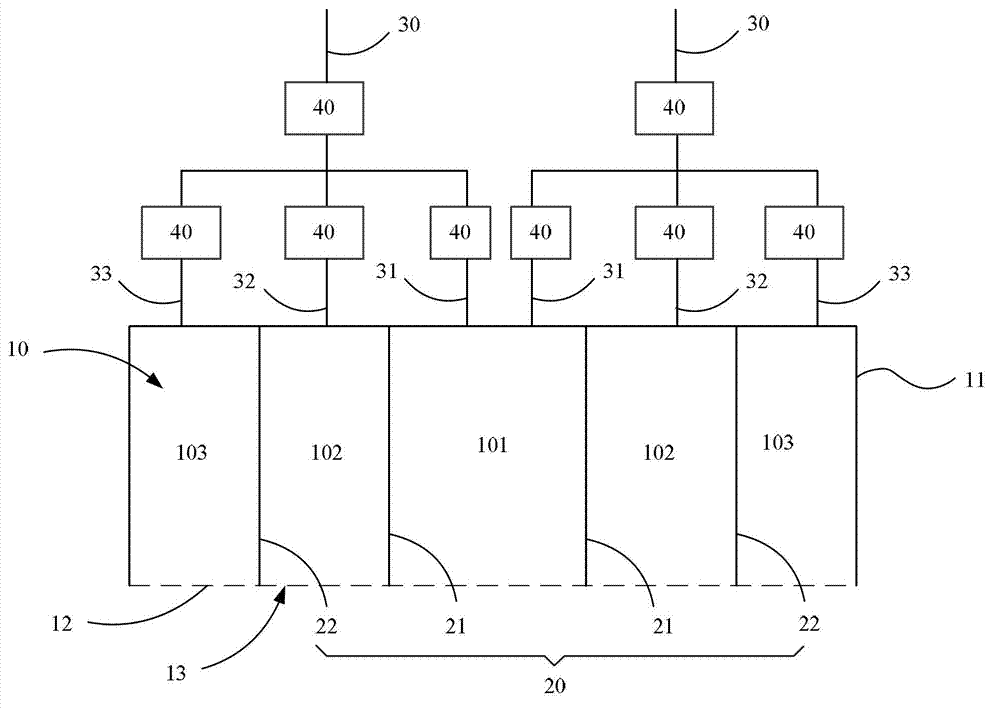

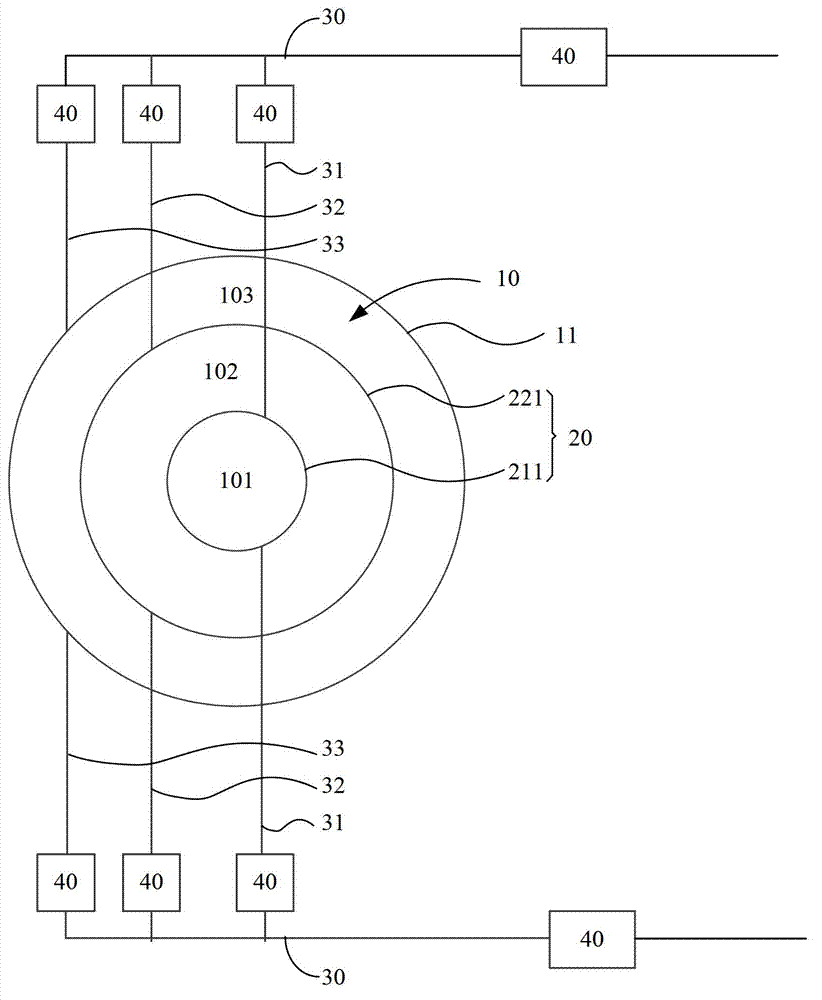

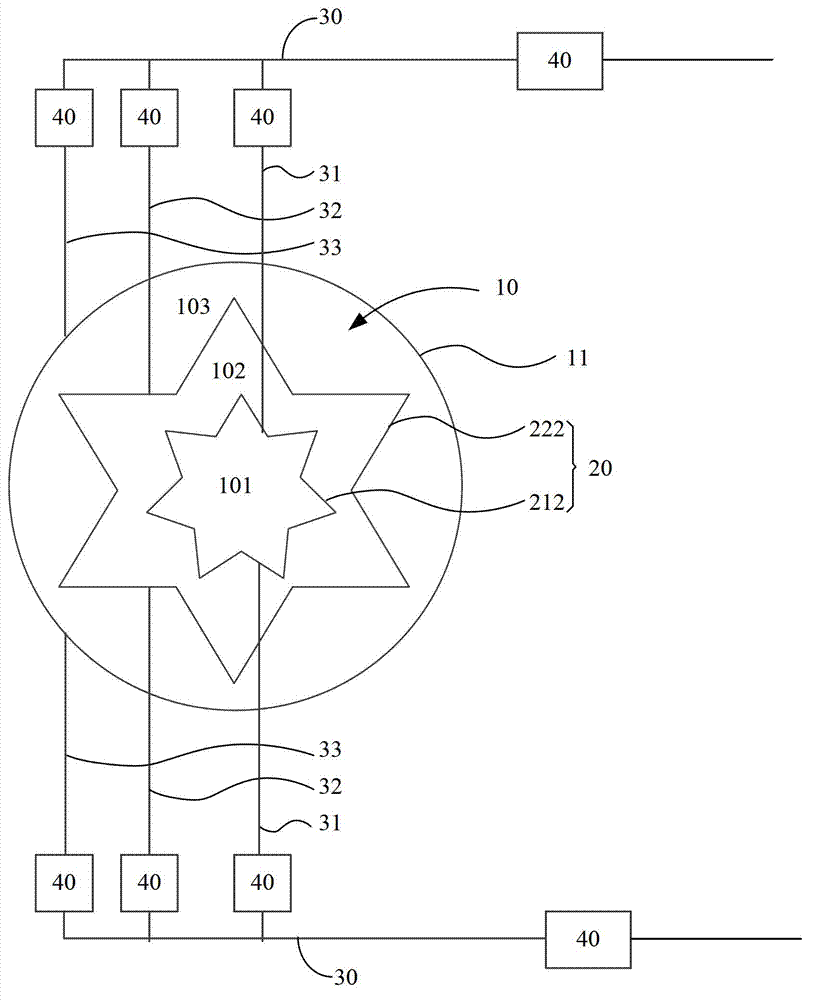

[0016] Please refer to figure 1 , the present invention provides a shower head, including a top plate 11 and a gas distribution plate 12, a gas diffusion chamber 10 is defined between the top plate 11 and the gas distribution plate 12; the gas distribution plate 12 has a plurality of The gas outlet channel 13 of the gas distribution plate 12 is connected to the gas diffusion chamber 10, and the gas passes through the gas outlet channel 13 to form an air flow field; the shower head also includes a partition 20; the partition 20 is arranged on the top plate 11 Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com