Floor board cast-in-situ method

A floor and cast-in-place technology, which is applied to floors, building components, buildings, etc., can solve the problems of reducing the overall strength of the building and the inability to form a criss-cross connection into a meshed steel structure, so as to improve the seismic performance of the building and avoid the support of the bottom formwork. Mold work, the effect of ensuring the overall strength of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

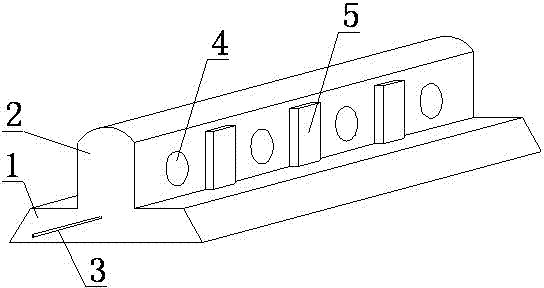

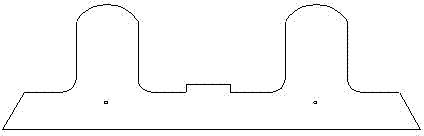

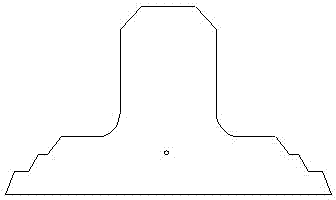

[0020] Such as figure 1 As shown, a floor floor cast-in-place method, first obtain the prefabricated part with the following structure, the prefabricated part is in the shape of a long strip as a whole, including a flat bottom plate part 1 and at least one convex part located above the bottom plate part 1 and arranged along the length direction Ridge 2, the prefabricated part is buried with reinforcing bars 3 along the length direction, the two ends of the reinforcing bar 3 have reserved sections extending out of the prefabricated part, and the ribs 2 are provided with a number of through holes 4 extending horizontally through the ribs along the length direction at intervals along the width direction . Protrusions 5 extending laterally outward are also provided on both sides between adjacent through holes 4 on the rib 2 . The cross-section of the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com