Immovable string hydraulic jetting technology for fracture acidizing and string for immovable string hydraulic jetting technology for fracture acidizing

A technology of hydraulic jetting, fracturing and acidizing, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. Problems such as low collection rate, to achieve the effect of reducing work intensity, operation risk, cost, and construction operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

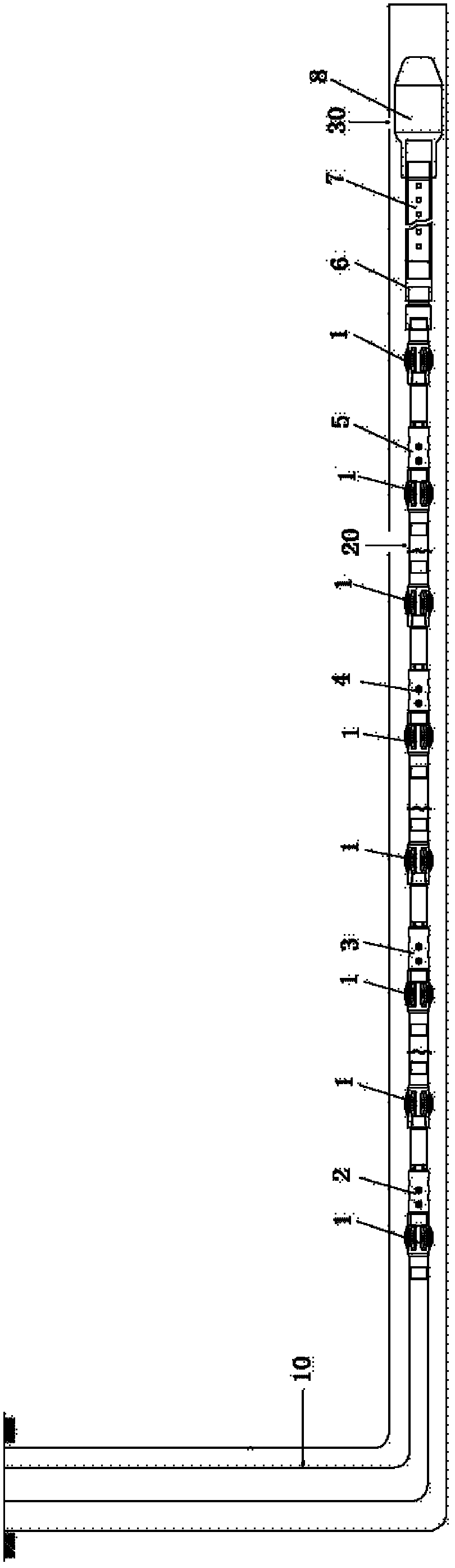

[0039] see figure 1 , a non-moving string hydrojet process for fracturing and acidification. It adopts the method of connecting multi-stage spray guns in series. After connecting the multi-stage pipes in series, it is lowered into the well. First implement N-layer fracturing to realize N-layer fracturing without moving the string, wherein, N>1, the number of balls is N, and the number of injectors is N;

[0040] The non-moving column hydrojet process for fracturing and acidizing is specifically operated according to the following steps:

[0041] Step 1, tool to well, measure size;

[0042] Step 2, use the specified size of the well gauge to pass the well to the bottom of the artificial well;

[0043] Step 3, lower the injection tool to the designed position;

[0044] Step 4, measure the depth electronically, and adjust the position of the pipe string;

[0045] Step 5, install the fracturing pipeline;

[0046] Step 6, the fracturing vehicle is emptied and pressure tested; ...

Embodiment 2

[0071] The embodiment of the present invention also provides a pipe string used in the hydraulic injection process of the fixed pipe string for fracturing and acidification, including oil pipe and a plurality of balls. Section 20, ball seat 6 and guide section 30 constitute,

[0072] The safety connection section 10 is arranged at the uppermost end, and the safety connection section 10 includes a safety joint;

[0073] The centralizing injection section 20 is arranged in the middle, and the centralizing injection section 20 includes centralizers 1 and injectors, the number of the centralizers 1 is 2N, the number of the injectors and the balls is N, the The injectors are arranged in the order of No. N to No. 1 from top to bottom. Each injector is connected to a centralizer 1 at both ends, and No. N injectors to N-1 injectors include injector bodies and equipment. For the inner sliding sleeve in it, the No. 1 injector 5 includes the injector body, and the inner sliding sleeve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com