Gas explosion suppression system and method for coal mine

A technology for gas and coal mines, which is applied to the gas explosion suppression system for coal mines and the field of explosion suppression, can solve the problem that the gas disaster prevention technology cannot meet the efficient and safe production of coal mines, etc., and achieves the effects of easy popularization, obvious effect and high work reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

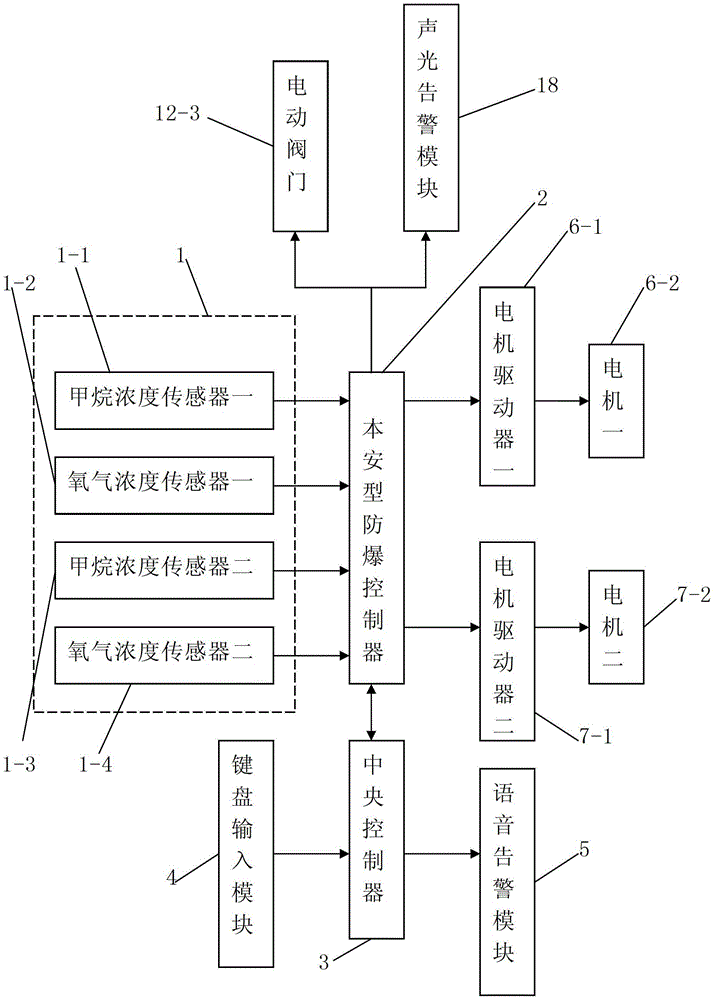

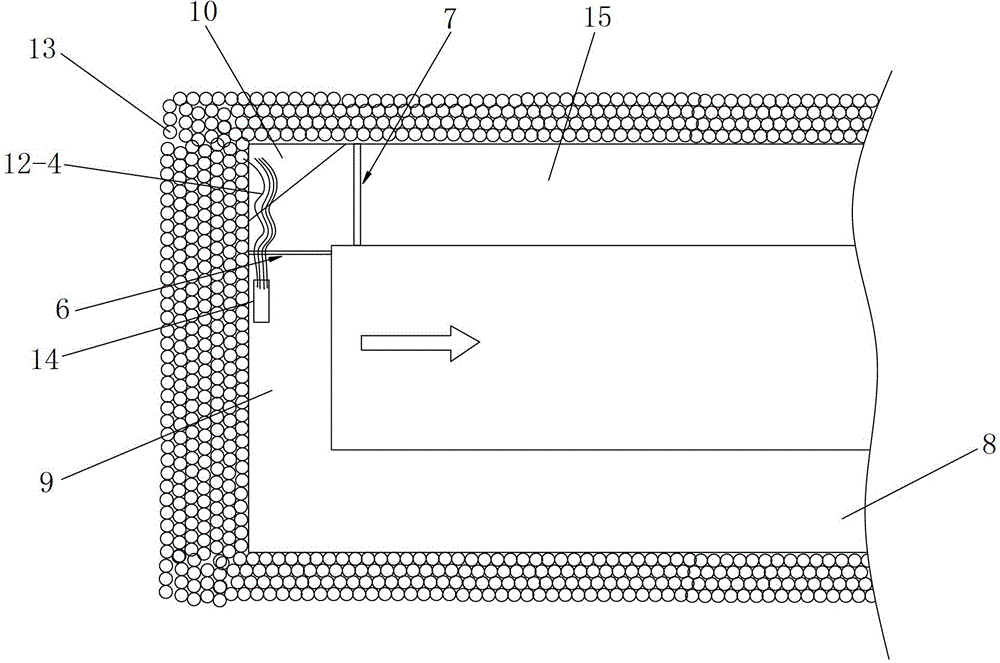

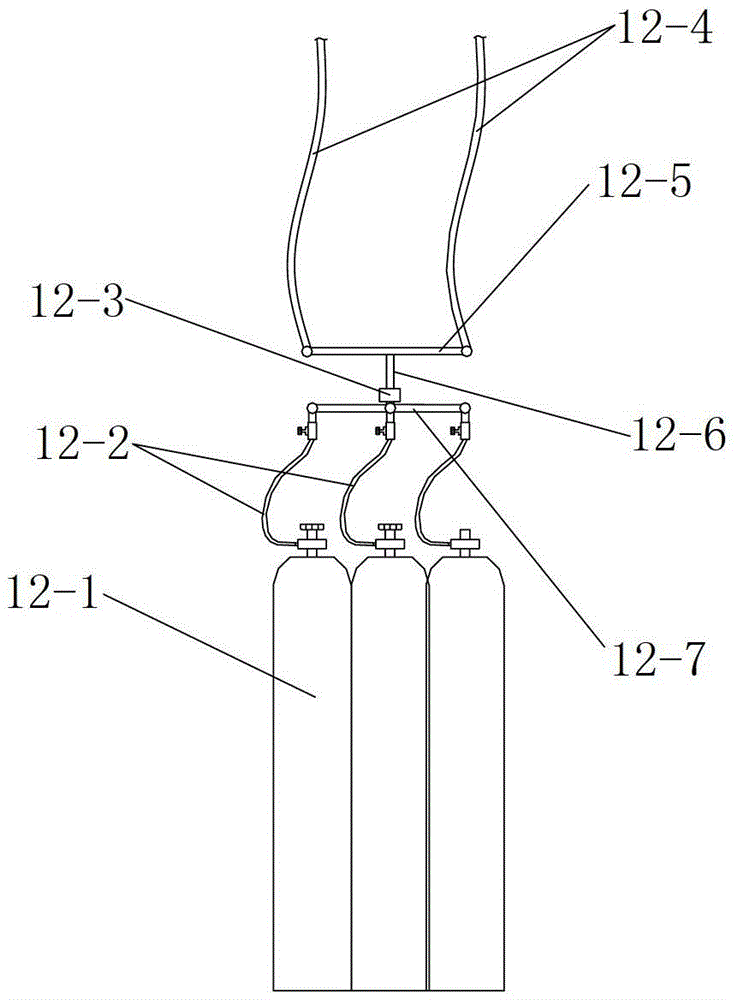

[0048] Such as figure 1 and figure 2 A gas explosion suppression system for coal mine is shown, which includes a gas detection module 1 for detecting methane concentration and oxygen concentration in the upper corner 10 of the coal mining working face and an intrinsically safe explosion-proof control system electrically connected to the gas detection module 1 device 2, the intrinsically safe explosion-proof controller 2 is electrically connected with an inert gas release device 12 for releasing inert gas to the upper corner 10 of the coal mining face to dilute the oxygen concentration and methane concentration, and for preventing the air inlet 8 The oxygen in the coal mining face enters the windshield device-6 of the upper corner 10.

[0049] In this embodiment, the method of diluting the oxygen concentration and methane concentration at the upper corner 10 of the coal mining working face is adopted, thereby reducing the oxygen concentration and methane concentration at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com