A method for on-line monitoring and ventilation linkage control of gas tanks in integrated pipe gallery

A comprehensive pipe gallery and gas technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of inability to realize timely and safe monitoring and dynamic linkage ventilation, and inability to ensure economical and effective release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

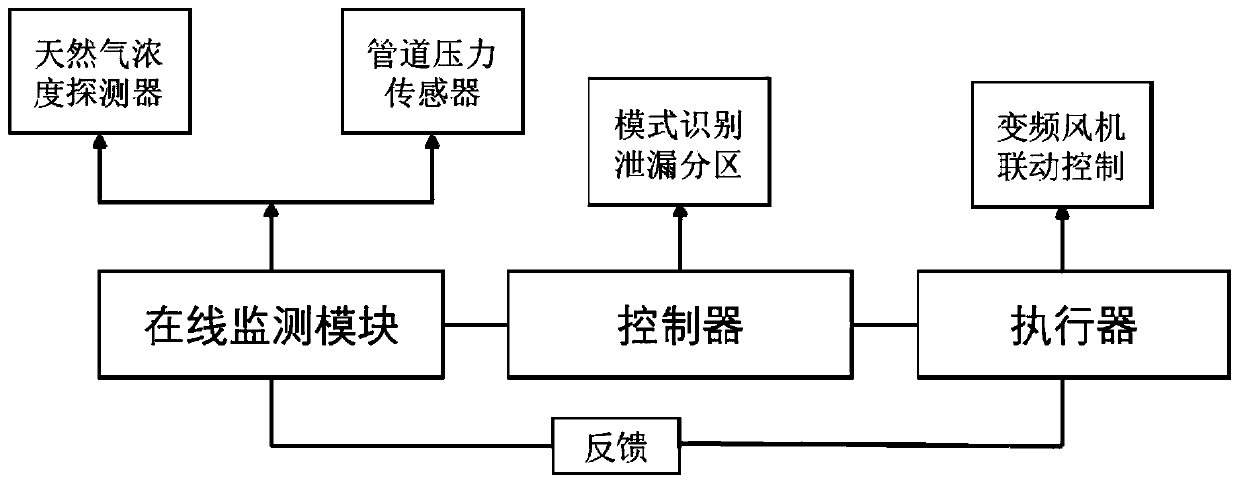

[0053] Specific implementation manner 1: The method for online monitoring and ventilation linkage control of the integrated pipeline gallery gas cabin of this embodiment is:

[0054] Step 1. The natural gas concentration monitor performs real-time monitoring of the natural gas concentration in the independent gas compartment of the integrated pipeline gallery;

[0055] The pipeline pressure sensor monitors the pressure of natural gas in the pipeline in real time;

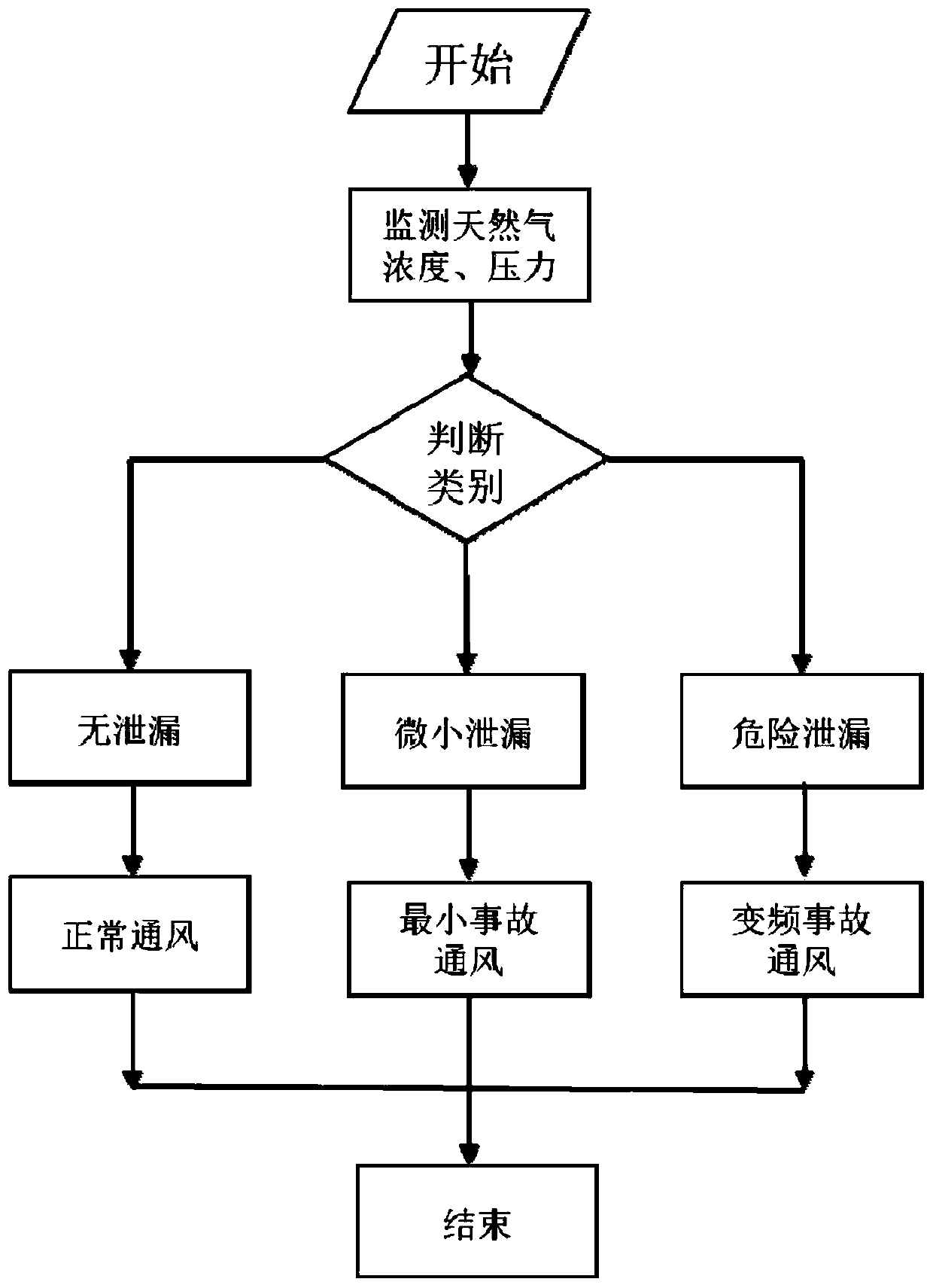

[0056] Determine whether the monitored signal corresponds to the category of "no leakage", "minor leakage", or "dangerous leakage",

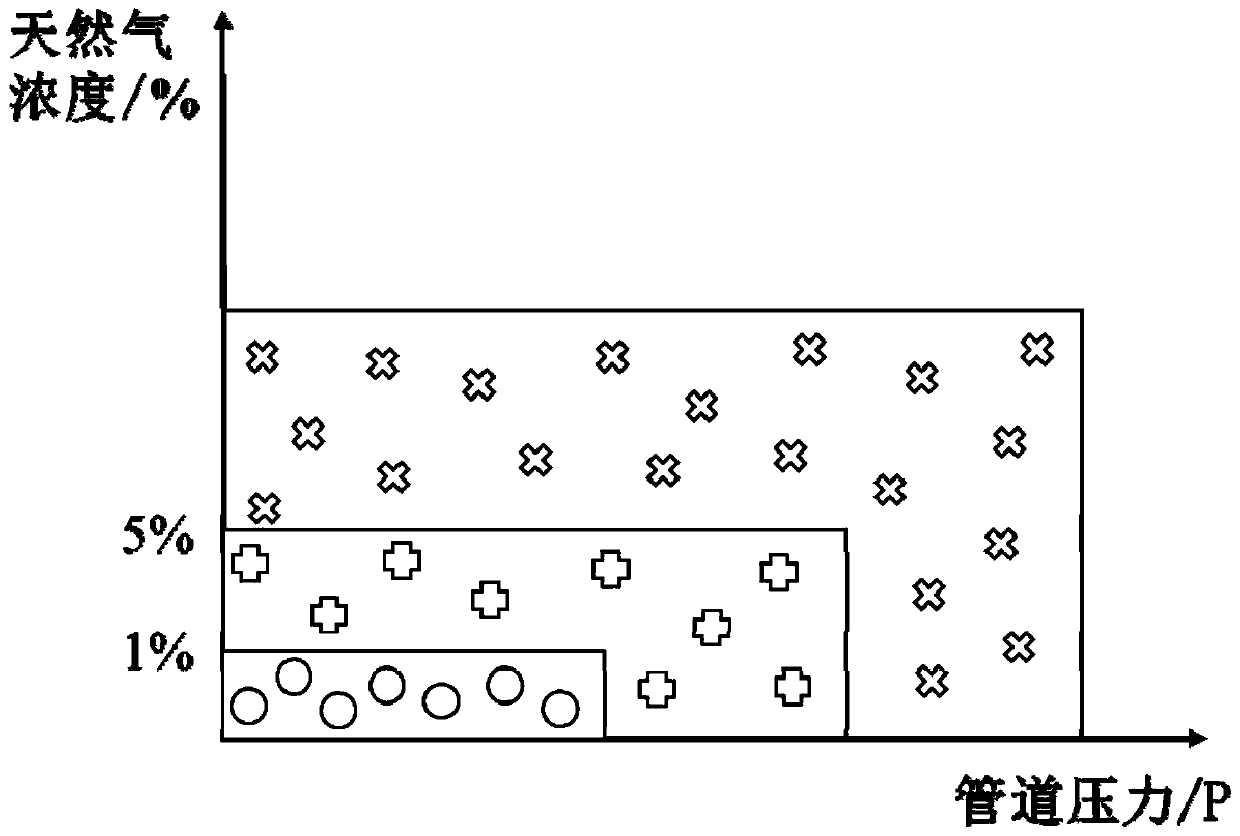

[0057] If the volume fraction of gas leakage concentration measured at the measuring point in the independent gas compartment of the integrated pipeline gallery is c<1%, it belongs to the category of "no leakage";

[0058] If the volume fraction of the gas leakage concentration measured at the measuring point in the gas independent compartment of the integrated pipeline gallery is 1%≤c≤5%, the ...

specific Embodiment approach 2

[0062] Specific embodiment two: this embodiment is different from specific embodiment one in that the specific setting process of the natural gas concentration monitor in the step one is:

[0063] Separate gas compartments are equipped with a fire compartment every 200m. Therefore, the principle of monitoring natural gas leakage in the compartment is to use the least number of monitors to quickly detect the leaked natural gas;

[0064] According to the operating pressure of the natural gas pipeline in the independent compartment of the integrated pipeline gallery (less than or equal to 1.6MP) and the most unfavorable orifice leakage condition (when the orifice is 0-6.35mm, the most unfavorable orifice leakage condition is 6.35mm). Simulation method (using ANSYS pre-processing software ICEM to establish a physical model of natural gas leakage and diffusion in the integrated pipeline gallery and perform grid division, give corresponding mathematical models and boundary conditions, use...

Embodiment approach

[0066] Implementation method: According to the operating parameters of the gas cabin pipeline, the numerical simulation method is used to simulate the concentration field distribution of natural gas leakage under the most unfavorable conditions, and the natural gas concentration monitors are arranged in sequence along the maximum change point of the concentration field distribution contour , And then orthogonalize the monitors at different locations, filter out the monitoring information and present the monitors with linear correlation, and all online monitor signals are wirelessly transmitted to the integrated detection module.

[0067] Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com