Full-angle light emitting diode (LED) light source body and production process for same

A technology of LED light source and LED chip, which is applied in the direction of light source, electric light source, light source fixation, etc., and can solve the problem that the LED light source body cannot realize full-angle light emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

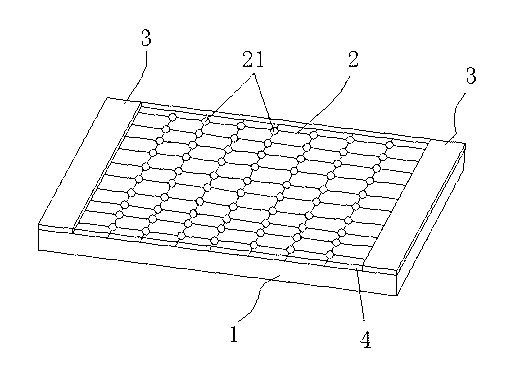

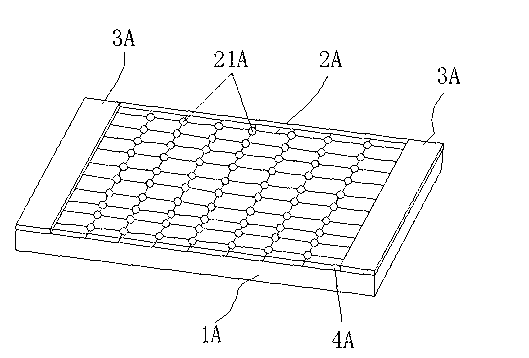

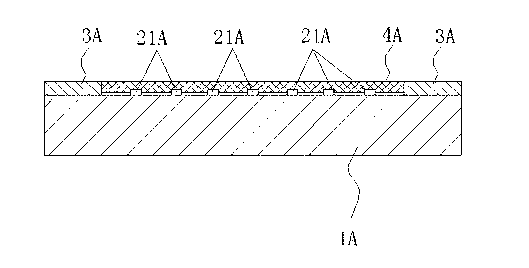

[0032] Embodiment one: if Figure 2 to Figure 3 As shown, a full-angle light-emitting LED light source body includes a light-transmitting carrier 1A, an LED chip group 2A, and a pole plate 3A; the LED chip set 2A is electrically connected to the pole plate 3A, and is fixed on the light-transmitting On the carrier 1A, the LED chipset 2A is covered with fluorescent glue 4A. The LED chipset 2A is composed of full-angle light-emitting LED chips, and the LED chipset is formed by at least two LED chips 21A connected in parallel or in series. The above-mentioned light-transmitting carrier 1A is a light-transmitting plate, and the light-transmitting plate is made of tempered glass or acrylic, and the light-transmitting plate is preferably made of tempered glass; the fluorescent glue 4A is made of transparent colloid, phosphor, surfactant and Agent composition, wherein the transparent colloid is silicone rubber, one-component or two-component.

Embodiment 2

[0033] Embodiment two: if Figure 4 to Figure 5 As shown, a full-angle light-emitting LED light source body, the LED light source body includes a light-transmitting carrier 1B, an LED chip group 2B and a pole plate 3B; the LED chip group 2B is electrically connected to the pole plate 3B, and is fixed on the light-transmitting On the carrier 1B, the LED chip group 2B is covered with fluorescent glue 4B. The LED chip group 2B is composed of full-angle light-emitting LED chips. The LED chip group is formed by connecting at least two LED chips 21B in parallel or in series. The above-mentioned light-transmitting carrier 1B is a light-transmitting polygon (see Figure 4 and Figure 5 , take the tetrahedron light-transmitting carrier as an example in this embodiment), the light-transmitting polygon is made of tempered glass or acrylic, and the light-transmitting polygon is preferably made of toughened glass; the above-mentioned fluorescent glue 4B is made of transparent colloid, flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com