Transducer for exciting and receiving multimode ultrasonic guided waves in pipe

A technology of ultrasonic guided waves and transducers, applied in the generation of ultrasonic/sonic/infrasonic waves, material analysis using sound waves/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of large volume, heavy quality, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

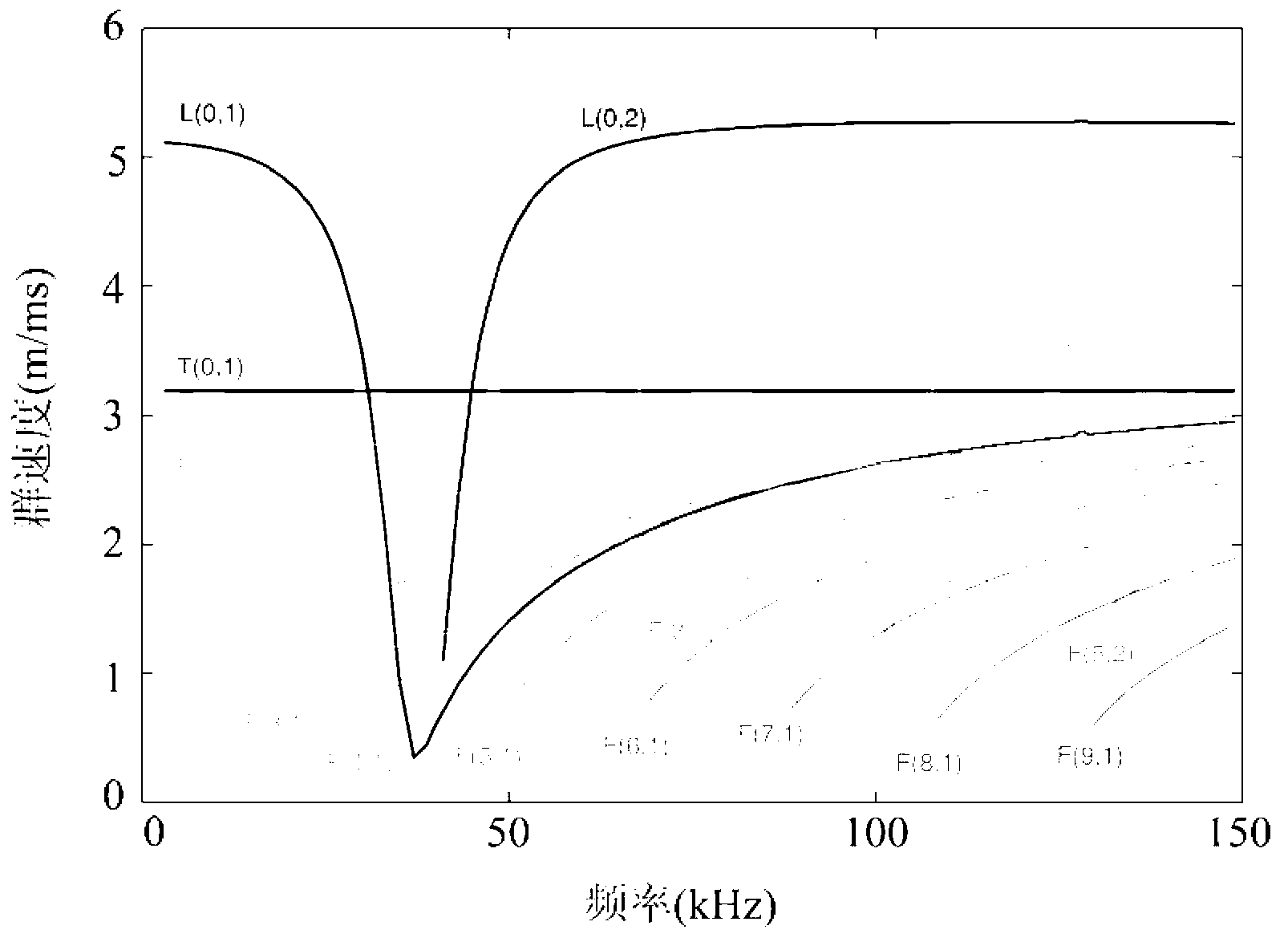

[0026]In this embodiment, the first shear piezoelectric wafer 2 is used to apply an axial load to the pipeline to excite the L(0,2) mode guided wave, and the second shear piezoelectric wafer 3 is used to apply a tangential load to the pipeline. The load is to excite the T(0,1) mode guided wave. In order to ensure that a sufficient number of transducers can be arranged on the outer wall of the pipe with different outer diameters to suppress the bending mode guided wave, the length direction of the transducer in this embodiment is along the The pipes are arranged axially.

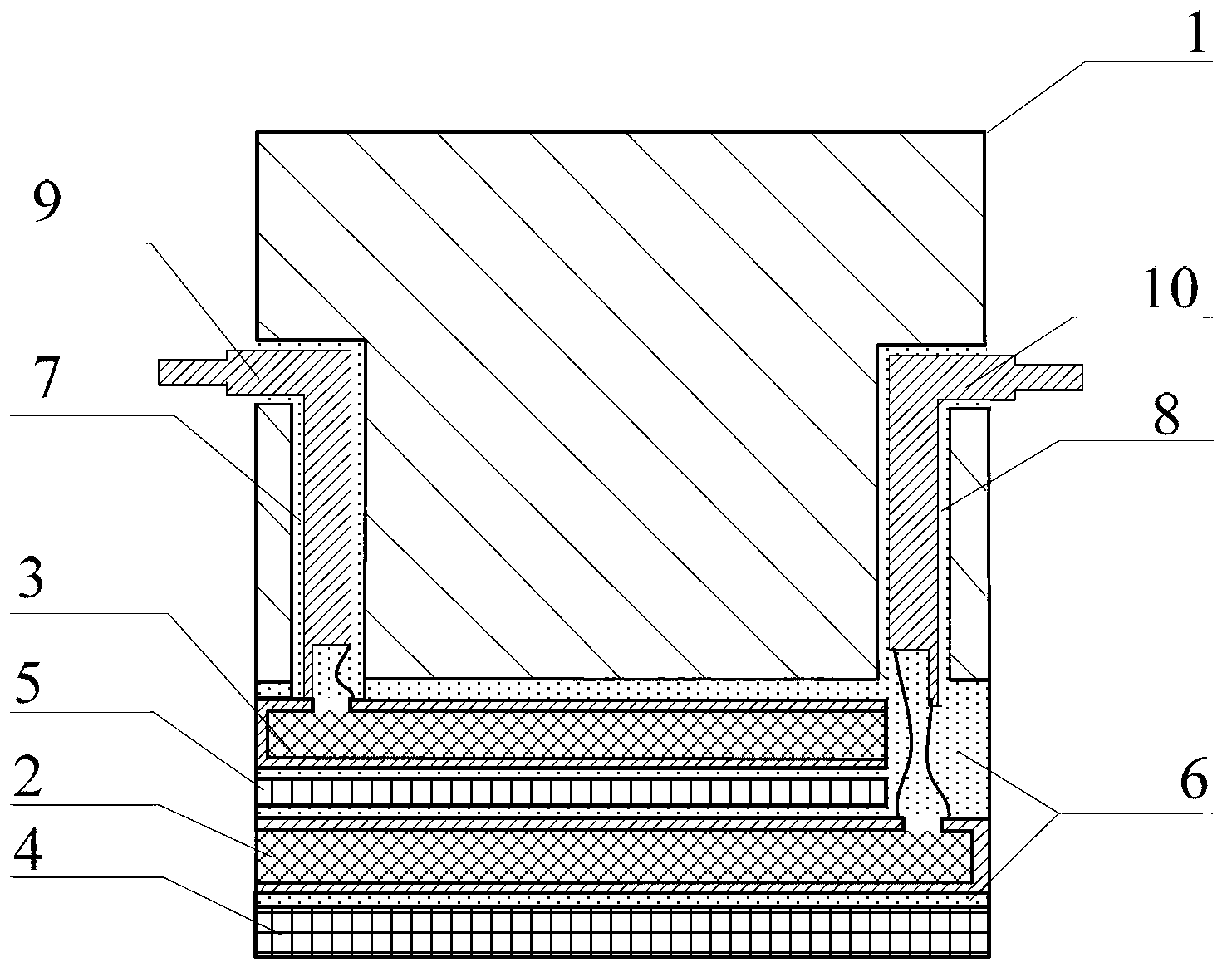

[0027] Transducer structure and design: such as figure 2 As shown, it is a transducer for applying multi-directional loads to hollow cylindrical structures such as pipes provided by the present invention, including a protective gasket 4, a first shear piezoelectric wafer whose polarization direction is consistent with the vibration direction 2. The second shear piezoelectric chip whose polarization directio...

Embodiment 2

[0039] In this embodiment, the first shear piezoelectric wafer 2 is used to apply a tangential load to the pipeline to excite the T(0,1) mode guided wave, and the second shear piezoelectric wafer 3 is used to apply an axial load to the pipeline. The load is to excite the L(0,2) mode guided wave, the length direction of the transducer is arranged along the axial direction of the pipe, the polarization direction of the first shear piezoelectric wafer 2 is along its width direction, and the second shear piezoelectric wafer 3 polarization direction along its length direction;.

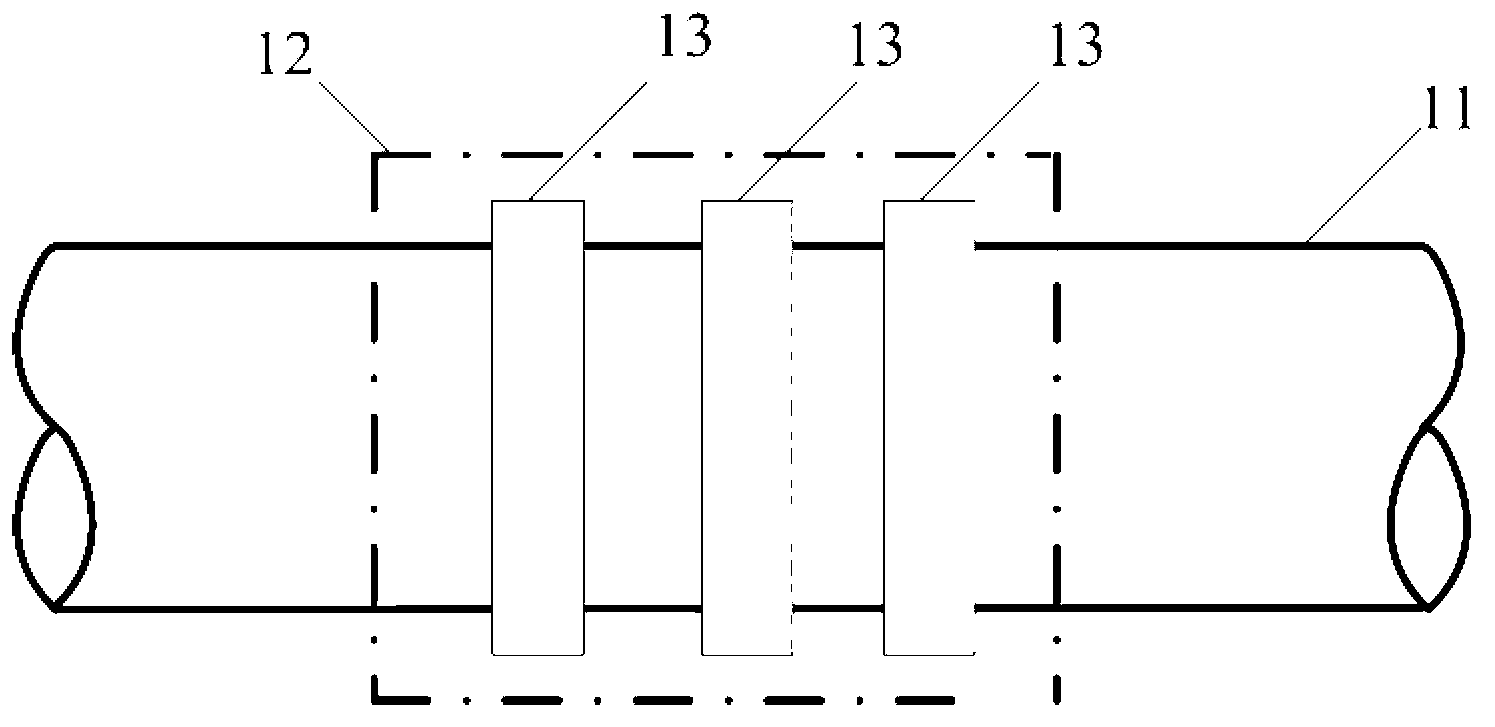

[0040] Parameters of the tested pipeline 11: inner diameter 206mm, wall thickness 6.5mm, length 5m, material 20# steel, no damage.

[0041] The structure and design of the transducer, the transducer array structure and installation position on the pipeline, the guided wave excitation signal used, the excitation frequency, and the method of exciting and receiving the guided wave are all the same as those in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com