Thermal resistance composition test device and method for LED (light emitting diode) lamp

A technology of LED lamps and LED chips, which is applied in the direction of single semiconductor device testing, material thermal conductivity, etc., can solve the problems of inability to measure thermal resistance, inconvenient design and application of LED lamps, etc., and achieve the effect of expanding measurement functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

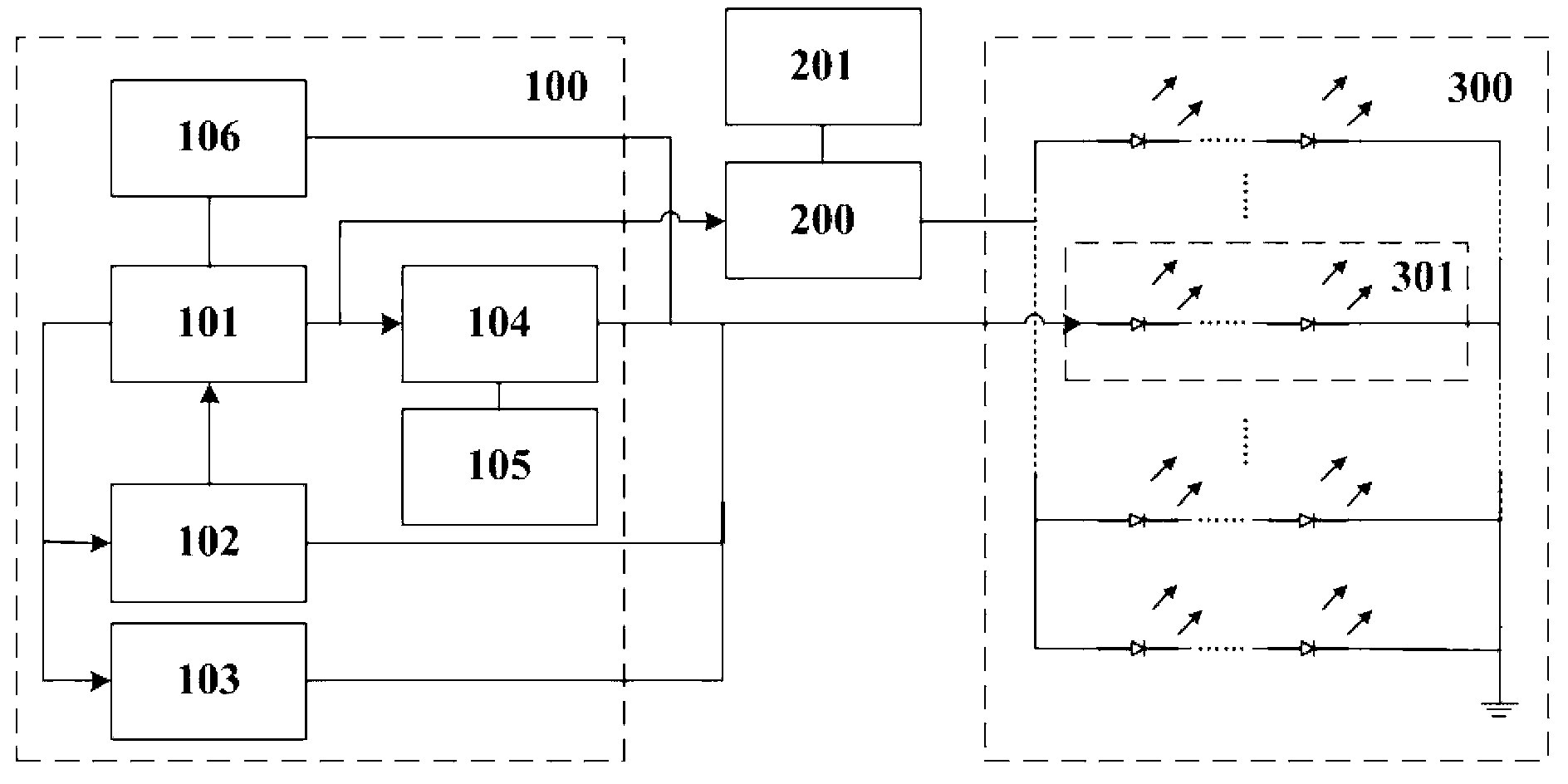

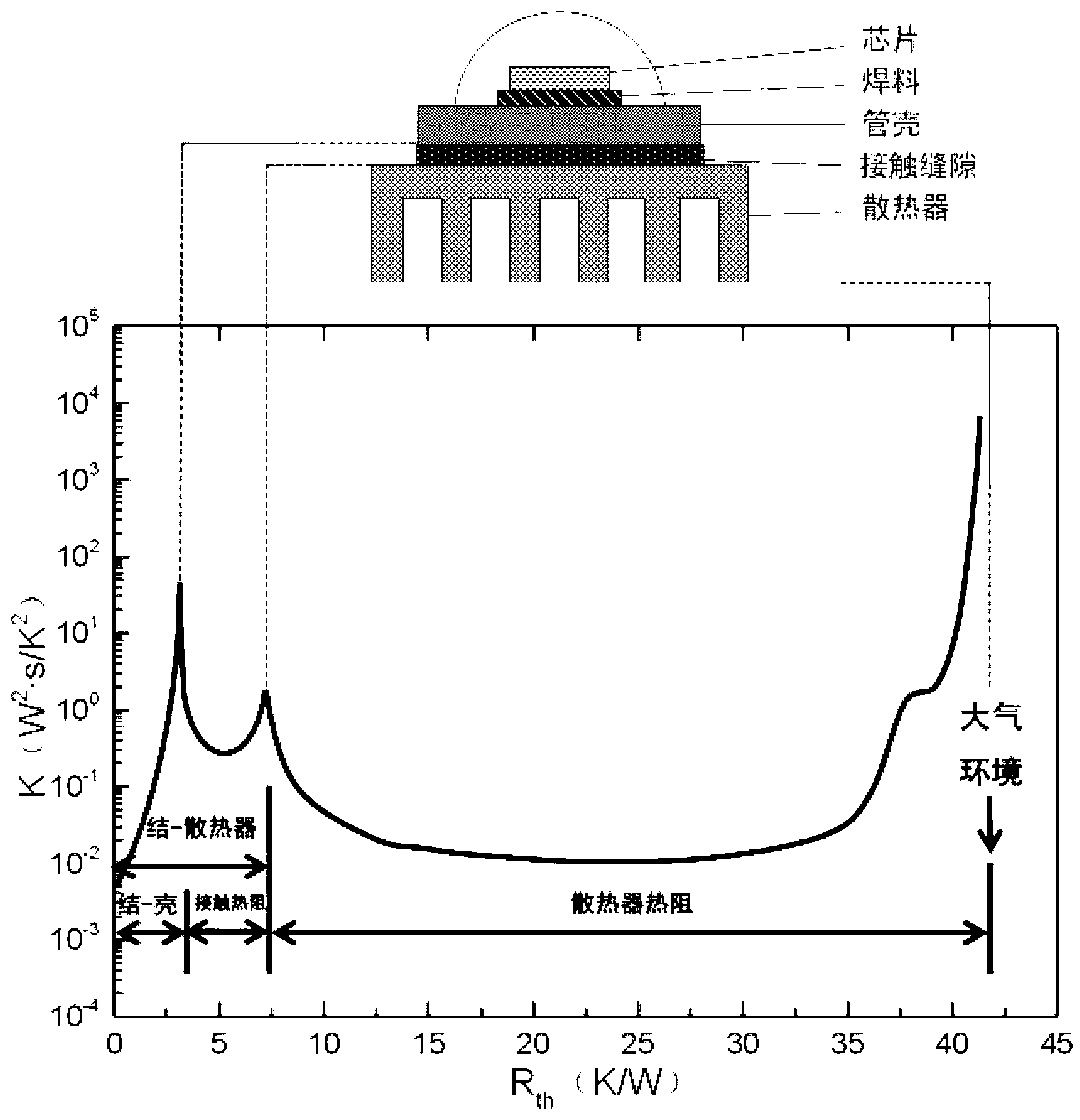

[0030] Choose the LED downlight produced by Zhuhai Shengyuan Tongtai Electronics Co., Ltd., and use this patent to test the thermal resistance of the LED chip to the heat sink. The structure of the lamp is that a plurality of high-power LED chips are connected in series and then connected in parallel. The LED chip shell is directly bonded to the surface of the radiator, and the heat dissipation method is heat conduction by a heat pipe. Before the test, first suspend and fix the tested lamp 300 in a confined space, select and separate a group of temperature measuring LED unit assemblies 301 as the temperature measuring device to be separately connected to the working power switch 104 interface of the temperature measuring LED unit assembly. The thermal resistance composition of the temperature measurement LED unit assembly 301 to the radiator is measured to achieve the purpose of obtaining the thermal resistance of the radiator, and the remaining LEDs are connected and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com