Method for monitoring best focal length of mask plate and exposure equipment

A technology of optimal focal length and mask plate, which is applied in the direction of microlithography exposure equipment, originals for photomechanical processing, exposure devices for photolithography, etc., can solve the problem of inaccurate response to product feature size changes, monitoring, and unfavorable Produce product feature size and other issues to achieve the effect of reducing mutual influence, high precision and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

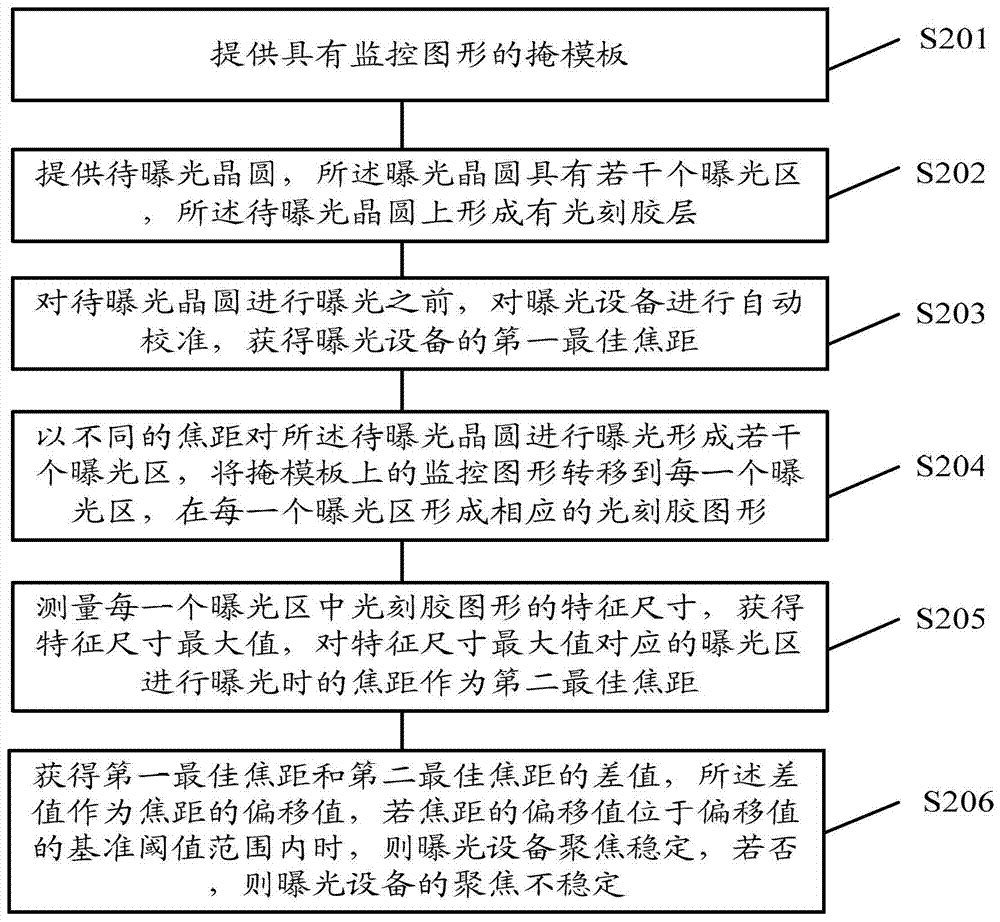

[0027] Although the existing exposure equipment can obtain the best focal length of the exposure equipment through the automatic calibration function, due to the influence of various disturbance factors such as the machine itself and the outside world during automatic calibration, the best focal length obtained is not accurate. When the best focal length exposes the photoresist layer of the product, the characteristic size of the photoresist pattern formed on the product changes, which is not conducive to the monitoring of the best focal length of the exposure machine and the characteristic size of the product.

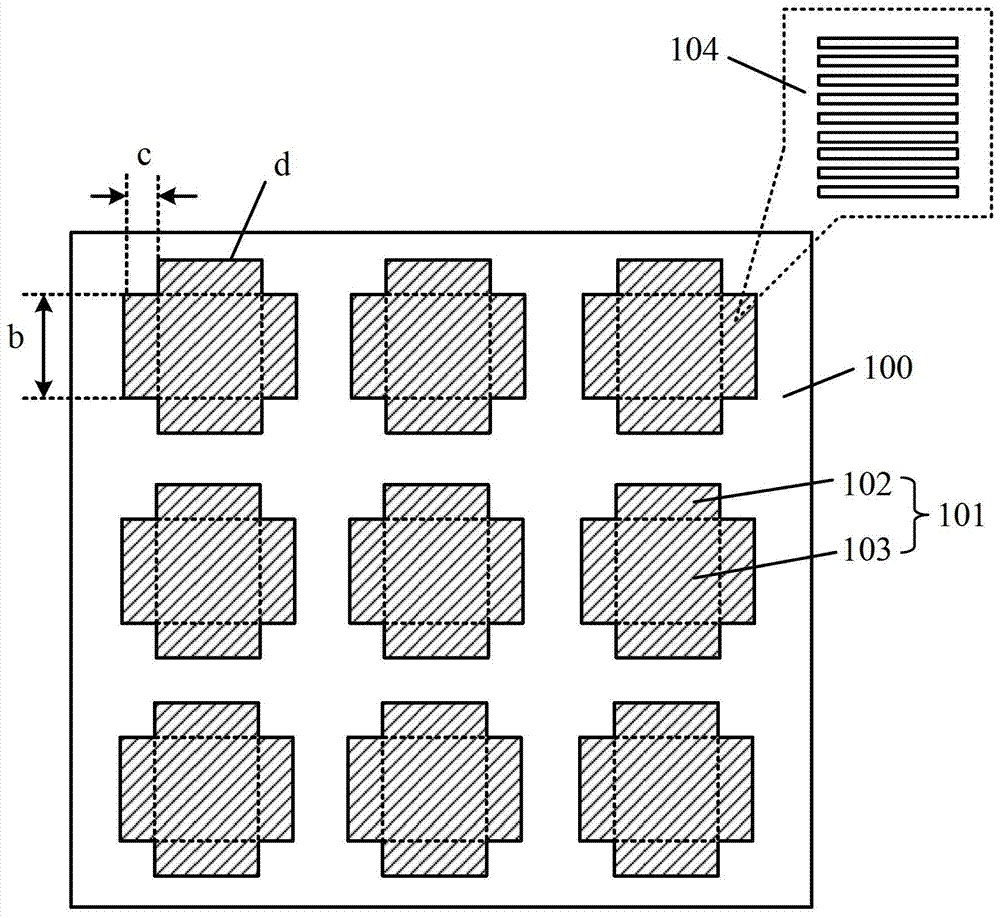

[0028] In order to solve the above problems, the embodiment of the present invention first proposes a mask, please refer to figure 1 , the mask plate 104 includes: a substrate 100 ; a monitoring pattern 101 on the substrate 100 , the monitoring pattern 101 includes a square body 103 and rectangular protrusions 102 on the side walls of the square body 103 .

[0029] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com