Rapid working clamp of pre-hanging type power distribution line de-icing engaged line

A transmission line, fast operation technology, applied in the direction of electrical components, cable installation, cable suspension device, etc., can solve the problems of staff fatigue, increased power outage time, safety accidents, etc., to achieve simple structure, large size Effect of contact area and short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

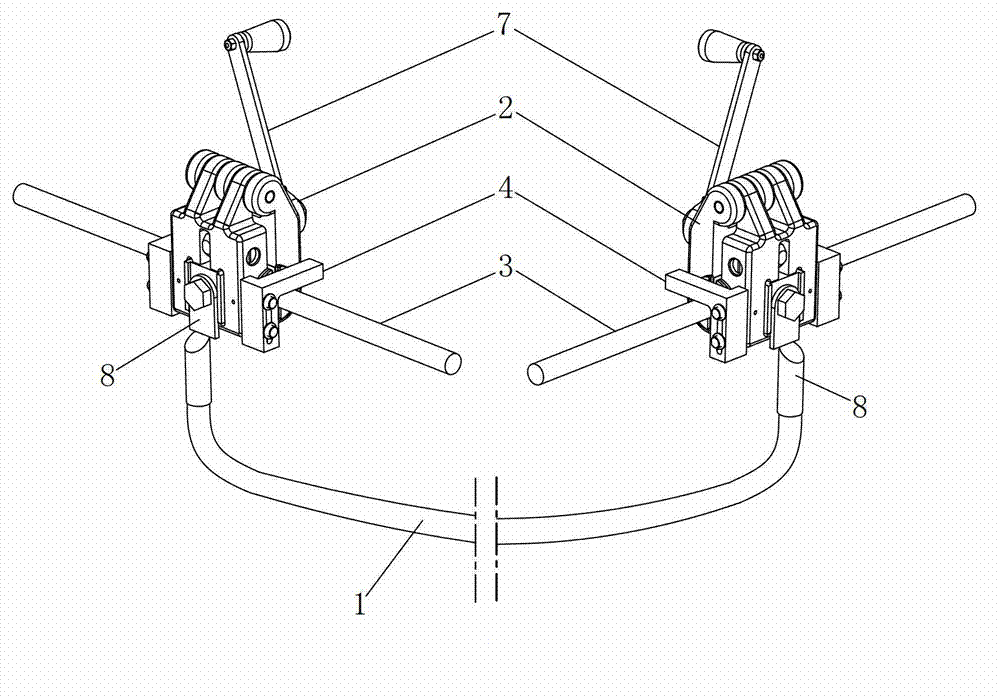

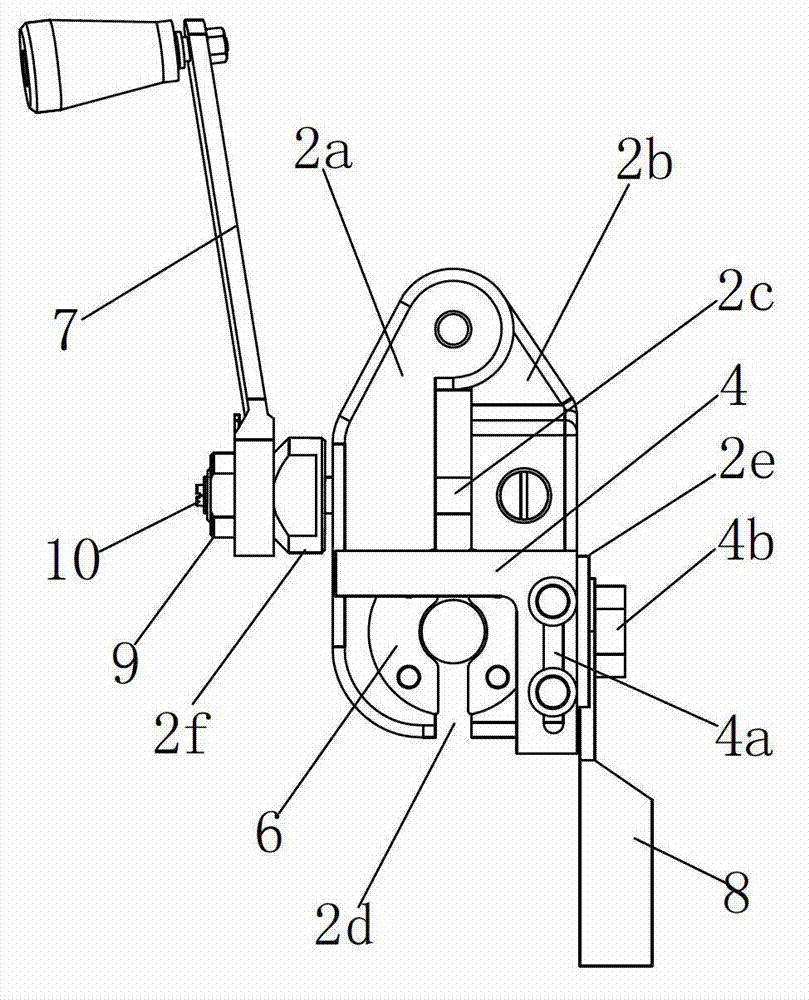

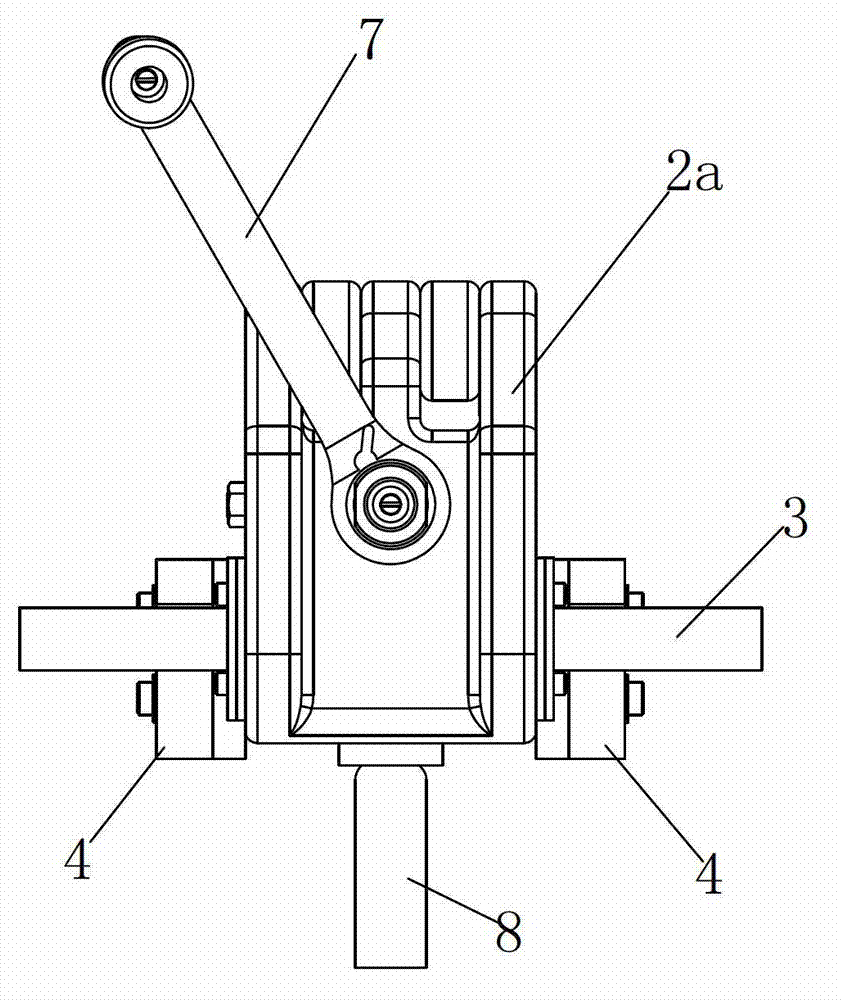

[0028] Such as figure 1 As shown, this embodiment provides a pre-mounted power transmission line ice-melting connection line fast operation fixture, including a short-circuit cable 1, the two ends of the short-circuit cable 1 are respectively connected to a wire hooking mechanism 2, and the wire The hook mechanism 2 includes a first clamping block 2a, a second clamping block 2b and a pull rod 2c, the upper end of the first clamping block 2a is movably connected with the upper end of the second clamping block 2b, and the lower end of the first clamping block 2a is connected to the second clamping block 2a. The opposite clamping surface of the lower end of the block 2b is respectively provided with bayonet sockets 2d for hanging the overhead wires 3, and the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com