Three-phase multi-split transformer-based CHB (Cascaded H-Bridged) cascade photovoltaic inverter circuit

A photovoltaic inverter and multi-split technology, which is applied in photovoltaic power generation, conversion equipment that converts irreversible DC power input into AC power output, and can be converted to DC without intermediate conversion, etc. The influence of the power generation efficiency of the system is greatly affected, so as to achieve the effect of convenient maintenance and management, reducing the current resistance value and avoiding parallel connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

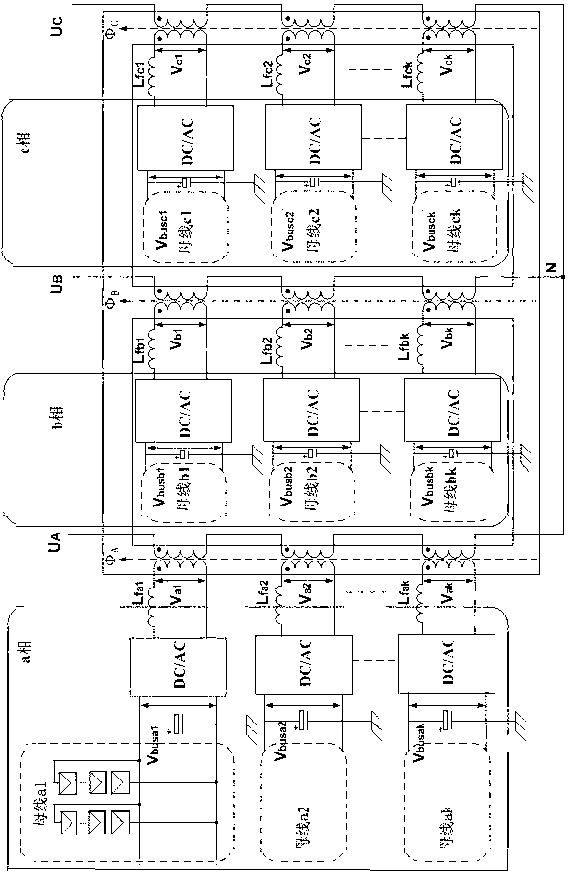

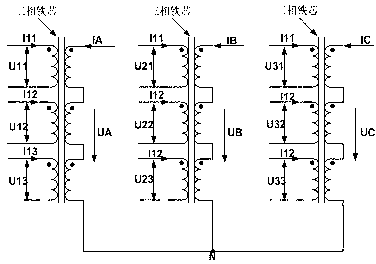

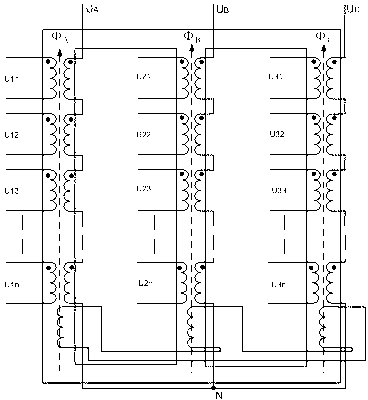

[0021] Such as figure 1 As shown, the specific embodiment of the present invention is to construct a CHB cascaded photovoltaic inverter circuit based on a three-phase multi-split transformer, including a three-phase multi-split transformer and a plurality of CHB cascaded inverter units, the CHB The cascaded inverter unit includes a DC bus, the DC buses of the plurality of CHB cascaded inverter units are multiple independent photovoltaic modules, and the three-phase split transformer is arranged between each inverter unit filter inductor Lf, each of the inverter units is a single-phase full-bridge circuit topology, after converting the current of the independent DC bus into a square wave, the filter inductor Lf filters the square wave into a sine wave containing harmonic components, the sine wave The wave is connected to the three-phase multi-spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com