A rapid kill method for blowout wells

A fast technology for oil and gas wells, applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve problems such as slow progress, unreliability, and high cost, and achieve asset preservation, reliability, and speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

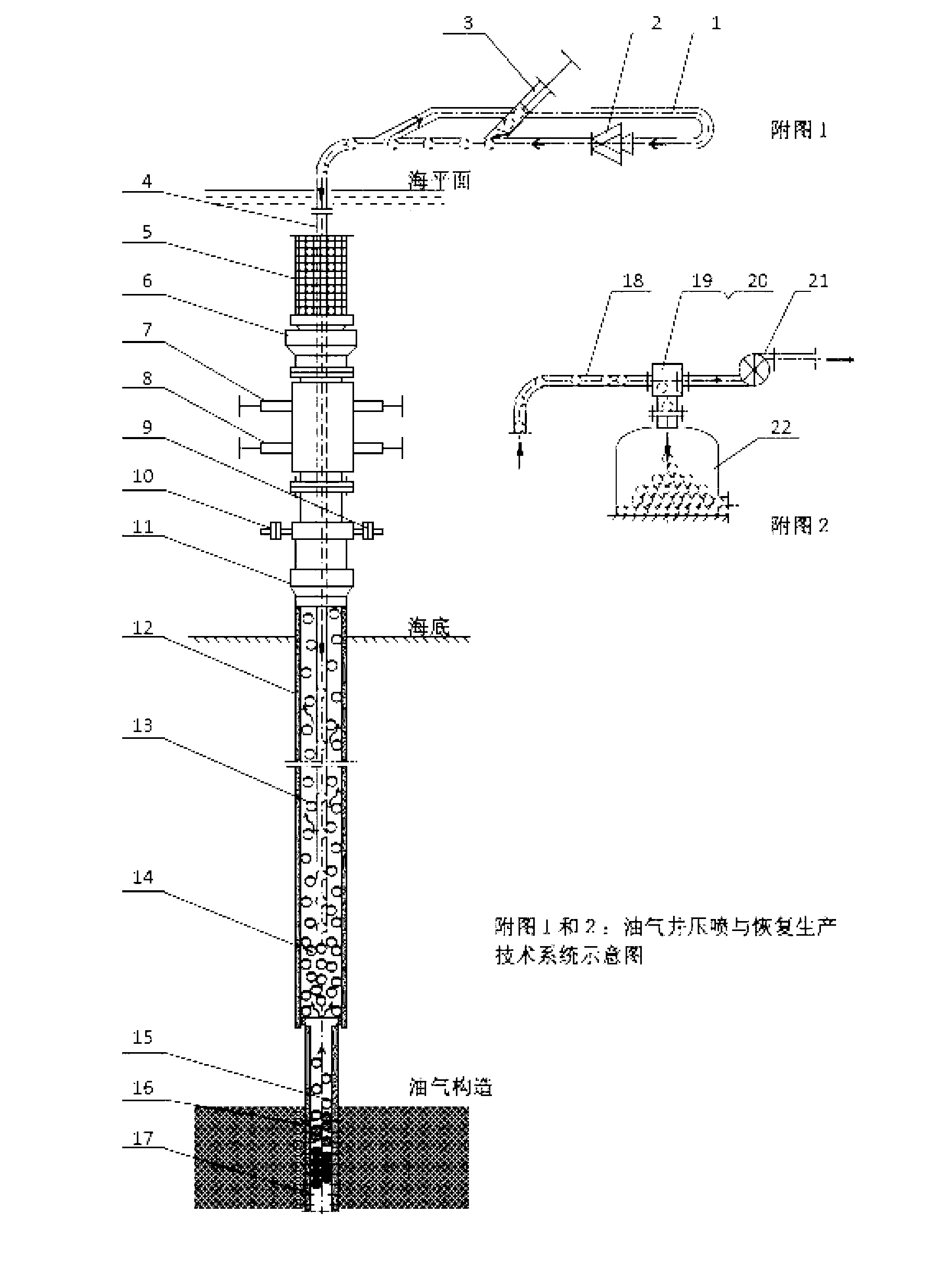

Image

Examples

Embodiment 1

[0015] Spherical is the preferred solid block shape for pressure blasting and retrieval. It is recommended that the size of the injection ball be less than 30% of the inner diameter of the oil and gas well.

Embodiment 2

[0017] Oil well blowout can use larger size pressure injection ball, as long as the vertical pipe can be safely inserted into the well deeper; natural gas blowout can use smaller size pressure injection ball, because the gas is lighter and needs pressure injection ball in the well The bottom is packed to form a small gap between the balls to prevent the passage of air.

Embodiment 3

[0019] When the blowout is strong at the beginning of blowout, you should use high-density spray balls, then use medium-density spray balls, and then use a large number of low-mass density spray balls. The large-mass density ball can be a steel ball or a steel ball; the medium-mass density ball can be a stone ball or a steel ball; the small-mass density ball can be a rubber or other material ball covered with a steel skin. Steel and other environmentally friendly materials can be used as the cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com