Novel reaction type sand making machine

A technology of counterattack sand making machine, which is applied in the direction of grain processing, etc. It can solve the problems of weak support strength and rigidity on the vertical shaft, no protection device for the hammer head support, and influence on sand making efficiency, etc., to achieve large adjustment stroke and novel structure , Improve the effect of sand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

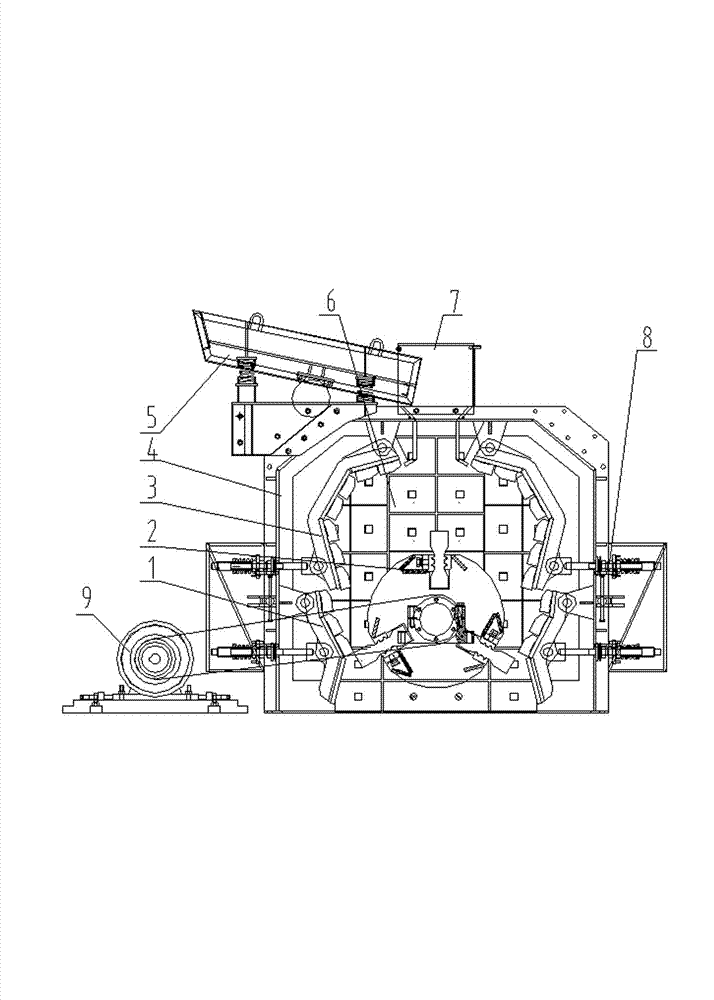

[0018] see figure 1 , a new type of impact sand making machine, including a frame 4, a feed port is provided at the upper end of the frame 4, a feed shield 7 is provided on the feed port, and a feed port is provided on one side of the feed port. The connected vibrating feeder 5 is provided with a liner 6 in the frame 4, and a three-blow bar rotor 2 is provided in the middle of the frame 4, and the three-blow bar rotor 2 includes an elliptical rotor 2 frame. There are three equidistant blow bars on the outer edge, and a welded blow bar seat B is provided on one side of the blow bar, and the blow bar seat B is protected by a welded guard plate. On the other side of the blow bar, there is a directional plug-in blow bar seat A. The barb of the blow bar seat A is hooked on the support plate, and the fastening bolts on the support plate tighten the blow bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com