Adjustable fixed-point mandril translation electric lifting platform

A lifting table and adjustable technology, applied in the field of lifting table, can solve the problems of long lifting time, difficult control of wire reels, high labor intensity, etc., and achieve the effects of stable power lifting, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

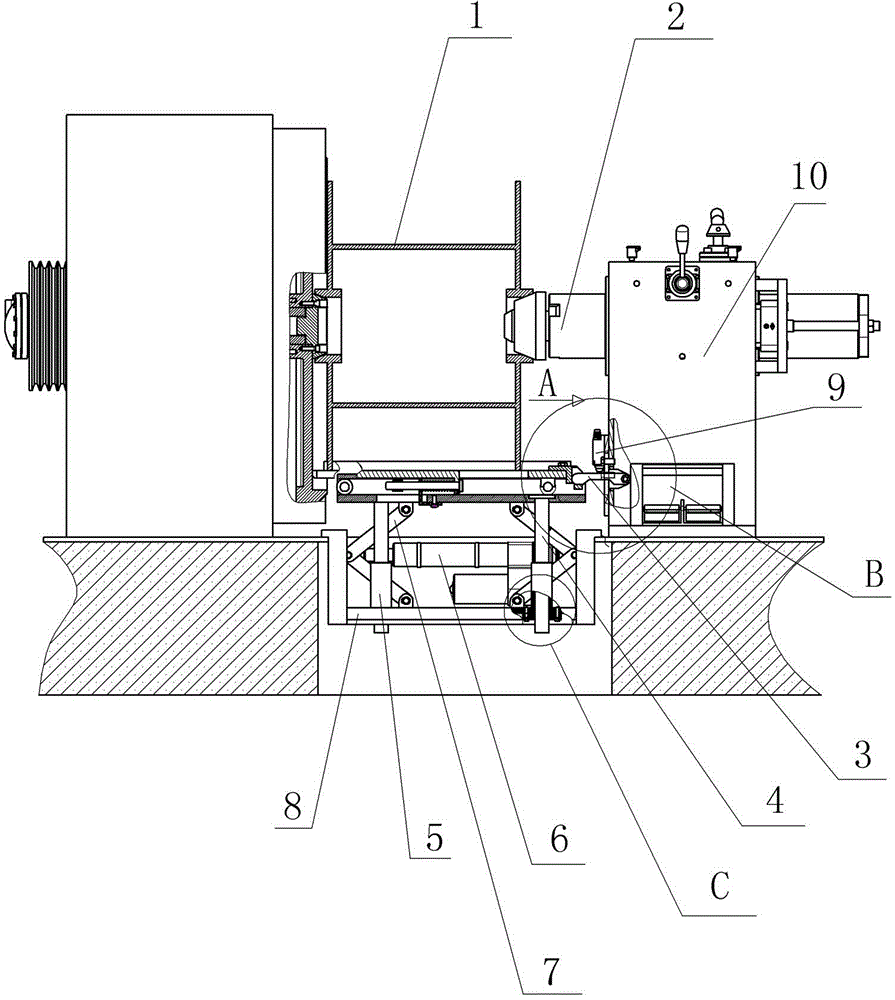

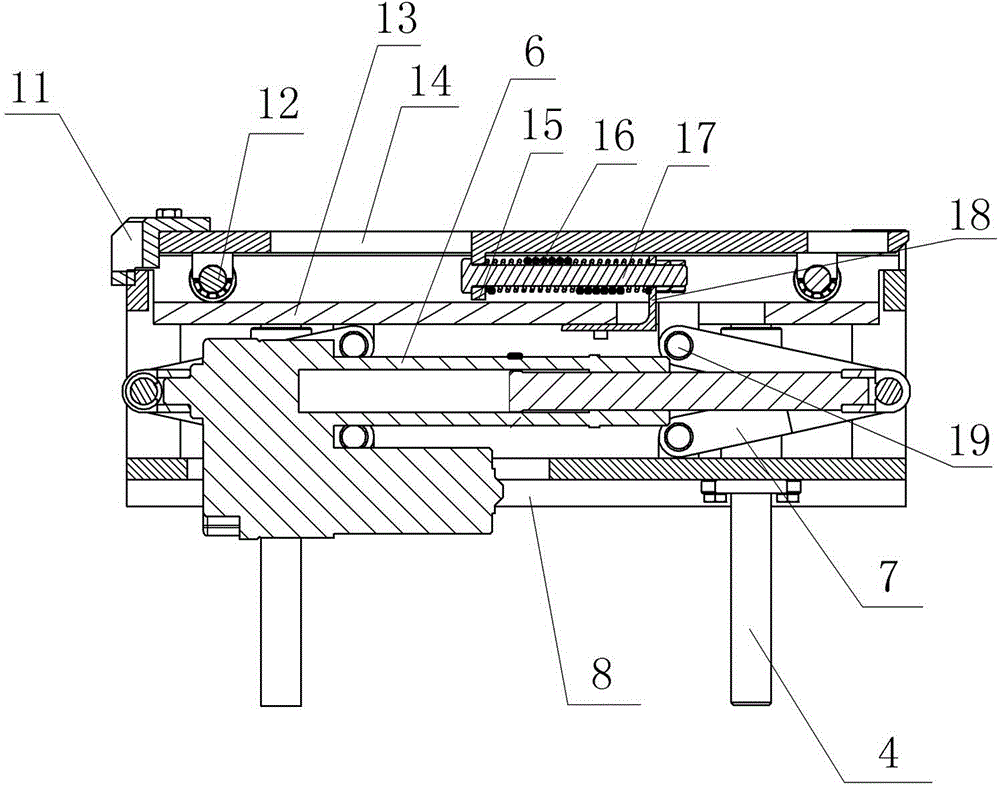

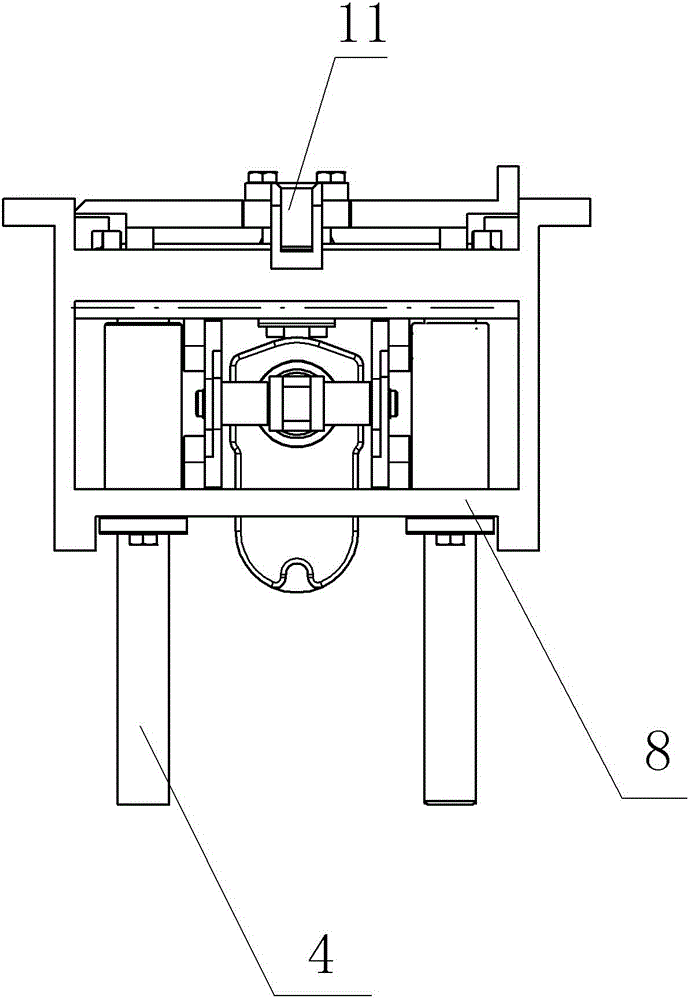

[0023] see Figure 1-8 , an adjustable fixed-point push rod translation electric lifting platform, including an outer support frame 8, an electric lifting device, a push rod translation device and a circuit control system, the electric lifting device is connected in the outer support frame 8, and the ejector rod translation device is connected to the The upper end of the electric lifting device, the electric lifting device includes an electric push rod 6, a curved arm 7 and a top plate 13, the bottom surface of the top plate 13 is connected with a guide column 4, the lower end of the guide column 4 is sleeved with a guide sleeve 5, and the guide sleeve 5 The lower end is fixed on the outer bracket 8. There is a stroke control device inside the electric push rod to ensure the control of the stroke position of the electric push rod. The left and right ends of the electric push rod 6 are respectively connected to the middle ends of the left crank arm and the right crank arm. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com