Vertical transportation construction method for building construction

A construction method and vertical transportation technology, applied in cranes and other directions, can solve the problems of increasing the risk of high-altitude operations, high maintenance costs, and strict requirements on the location and structure of the tower crane foundation, and achieve the effect of solving the problem of vertical transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

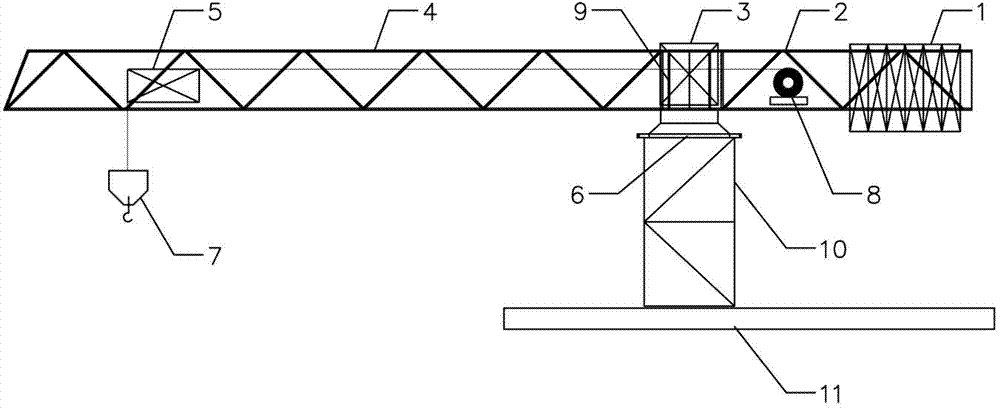

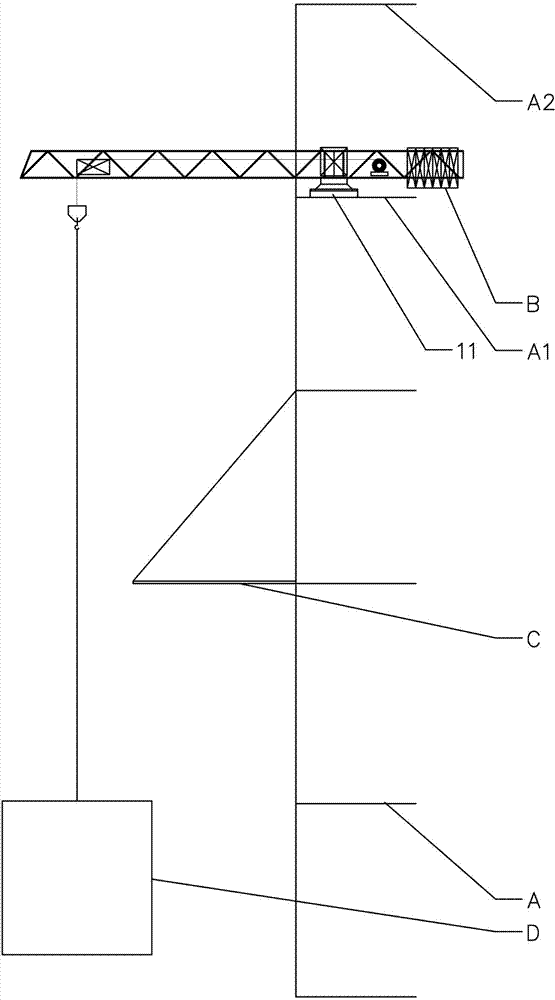

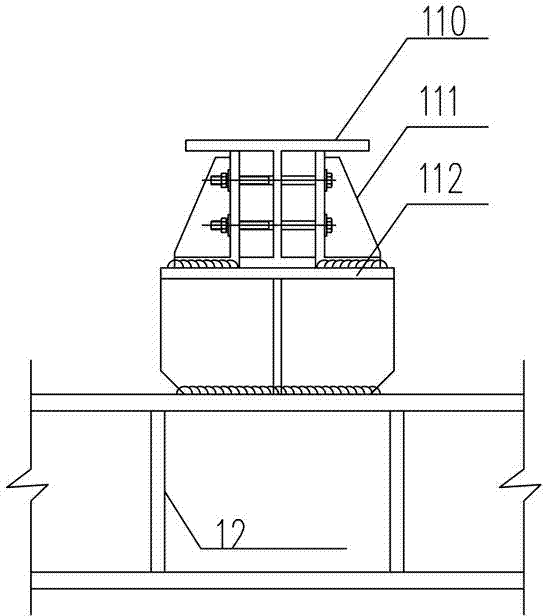

[0056] Such as figure 1 and figure 2 As shown, the cantilever crane used in the vertical transport construction method for building construction provided by the present invention can specifically include a cantilever suspension support 6, a driver's cab 3 with a power transmission system and a control system, a balance arm 2, and a boom 4 , counterweight 1, traction luffing trolley 5, wire rope reel 8 and hook 7, such as figure 2 Shown is a cantilever crane installed on floor slab A of one floor, as figure 1 Shown is the jib crane installed on the roof of a building. Tower base 11 will be set on floor slab or roof. The tower base 11 is fixed on the main structure of the floor slab or the roof, the cantilever hanger support 6 is fixed on the tower base 11, the boom connecting seat 9 is arranged on the cantilever hanger support 6, and the boom connection The two ends of seat 9 are fixedly provided with balance arm 2 and jib 4, and the three are connected into a straight li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com