Adsorption tank and treatment technology for wastewater treatment

A waste water treatment and adsorption pool technology, which is applied in the direction of adsorption water/sewage treatment, etc., can solve the problems that the agitator cannot be disturbed, reduce the economic performance of adsorption treatment, and increase the power consumption of the adsorption pool, so as to improve the utilization rate and benefit Adsorption effect, anti-sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

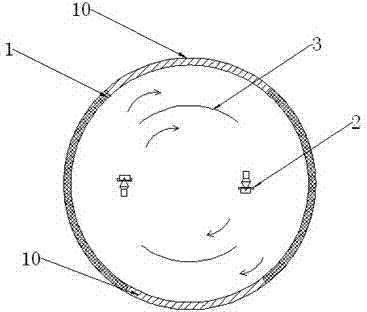

[0056] The adsorption pond used for wastewater treatment described in this embodiment, such as figure 1 with figure 2 shown, including:

[0057] Pool body 1, the pool body 1 is circular; two arc-shaped deflectors 3 are arranged in the pool body, and the two arc-shaped deflectors are respectively concentric with the arc-shaped side walls 10 located on the outside thereof Setting, one end of the pool body 1 is provided with a water inlet 4, preferably the water inlet is arranged on the outside of the arc-shaped deflector 3 in this embodiment, the advantage of such arrangement is that the adsorption effect can be improved, and the water inlet First enter the circulation on the outside of the arc-shaped deflector 3, and then enter the inside of the arc-shaped deflector 3 after being fully mixed with the adsorbent; a water outlet 5 is provided at the other end of the pool body;

[0058] Two pushing flow devices 2 are arranged between a pair of arc-shaped deflectors 3, and the pu...

Embodiment 2

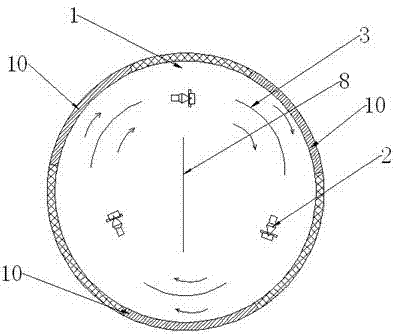

[0066] The adsorption pond used for wastewater treatment described in this embodiment, such as image 3 shown, including:

[0067] Pool body 1, the pool body 1 is circular; three arc-shaped deflectors 3 are arranged in the pool body, and the three arc-shaped deflectors are respectively arranged concentrically with the arc-shaped side walls 10 located on the outside thereof A water inlet 4 is provided at one end of the pool body 1. In this embodiment, the water inlet is preferably arranged on the outside of the arc deflector 3, and a water outlet 5 is provided at the other end of the pool body. ;

[0068] A flow pushing device 2 is arranged between each pair of adjacent arc deflectors 3, and the flow pushing directions of the three flow pushing devices 2 are uniformly arranged in a clockwise direction; the flow pushing device 2 pushes The outflowing liquid flows to the edge of the arc-shaped deflector 3, part of the liquid enters the outside of the arc-shaped deflector 3, and...

Embodiment 3

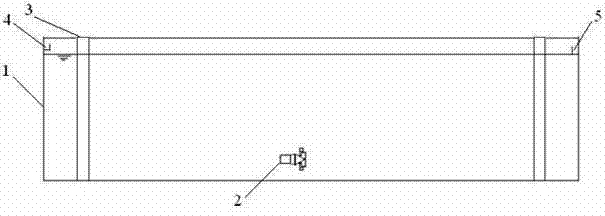

[0076] The adsorption pond used for wastewater treatment described in this embodiment, such as Figure 4 shown, including:

[0077] Pool body 1, described pool body 1 is provided with four sidewalls, wherein two opposite sidewalls are parallel planar sidewalls 9, and other two opposite sidewalls are arc-shaped sidewalls 10, and the two arc-shaped sidewalls The side wall 10 is curved toward the outside of the pool body 1, and a water inlet 4 is arranged at one end of the pool body. In this embodiment, the water inlet is arranged outside the arc-shaped deflector 3, and the other end is There is a water outlet 5; the maximum length between the two curved side walls 10 of the adsorption pool and the length between the two plane side walls 9 are equal to 3,

[0078] Two arc-shaped deflectors 3, the two arc-shaped deflectors 3 are arranged in the pool body 1, and the inner sides of the two arc-shaped side walls 10 are respectively arranged, and the two arc-shaped deflectors The fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com