On-line measurement method of bus current of aluminium electrolysis cell

A technology of busbar current and measurement method, applied in the field of aluminum electrolysis, can solve the problems of limited measurement method, unsatisfactory, large cathode current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

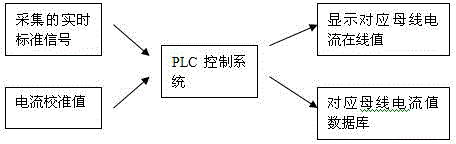

[0016] The specific steps of the on-line measurement method for the bus current of the aluminum electrolytic cell are as follows: (such as figure 1 shown)

[0017] 1) Collect real-time standard signals of 0-10V through the SQ-3 DC millivolt input isolation transmitter;

[0018] 2) Use the current measuring instrument to measure the instantaneous current value of the busbar. The measurement position is selected at two points on the measured current busbar. The busbars at the two points do not meet, and the distance between the two points is 30-50cm;

[0019] 3) Input the measured current value into the PLC controller as the calibration current value, and start the control program to realize online monitoring and data collection of the output current of all cathode soft master tapes.

[0020] The selected point and the signal line should be tightened with bolts, and the signal line should be 2*2.5mm shielded line.

[0021] E.g figure 2 The shown 186KA electrolytic cell measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com