Waterpower self-excited oscillation jet flow vibratory pile sinking device and pile sinking technology

A technology of self-excited oscillating jet and vibratory pile sinking, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large damage at the bottom of the pile body, reduced pile sinking efficiency, and unstable pile body, etc., and achieves a solution Pile sinking speed and the problem of breaking through underground obstacles, improving construction efficiency and ensuring the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Attached Figure 1-16 , To further describe the present invention:

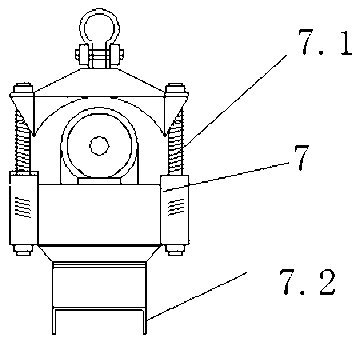

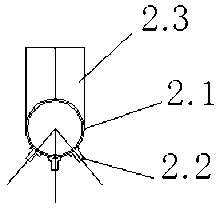

[0040] The hydraulic self-excited oscillating jet vibrating pile sinking device mentioned in the present invention includes a reinforced concrete pile body 1, a jet pipe with a self-excited oscillating jet nozzle 2, a water pipe 3, a quick docking movable elbow 4, and a high-pressure hose 5 , The high-pressure water pump group 6, the vibrating hammer part 7 and the integral spreader 8, the reinforced concrete pile 1 is a sheet pile, with a square pile head 1.3 and a lifting ring 1.5 in the middle of the top, and the vibrating hammer connecting device 7.2 and the vibrating hammer part 7 connection; the two sides of the sheet pile are respectively provided with pile tenon groove 1.1 and pile tenon groove 1.2, the length of the pile tenon groove 1.1 and the pile tenon groove 1.2 is the same as the length of the sheet pile, The inner side of the pile tenon groove 1.1 and the pile concave tenon groove 1.2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com