Light insulation batten wall body anti-cracking joint treatment method

A technology for joint treatment and thermal insulation strips, applied in the direction of walls, building components, buildings, etc., can solve problems such as large shrinkage stress, and achieve the effect of solving easy cracking and ensuring installation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

[0025] A method for treating anti-cracking joints of light-weight thermal insulation slat walls, the steps are as follows:

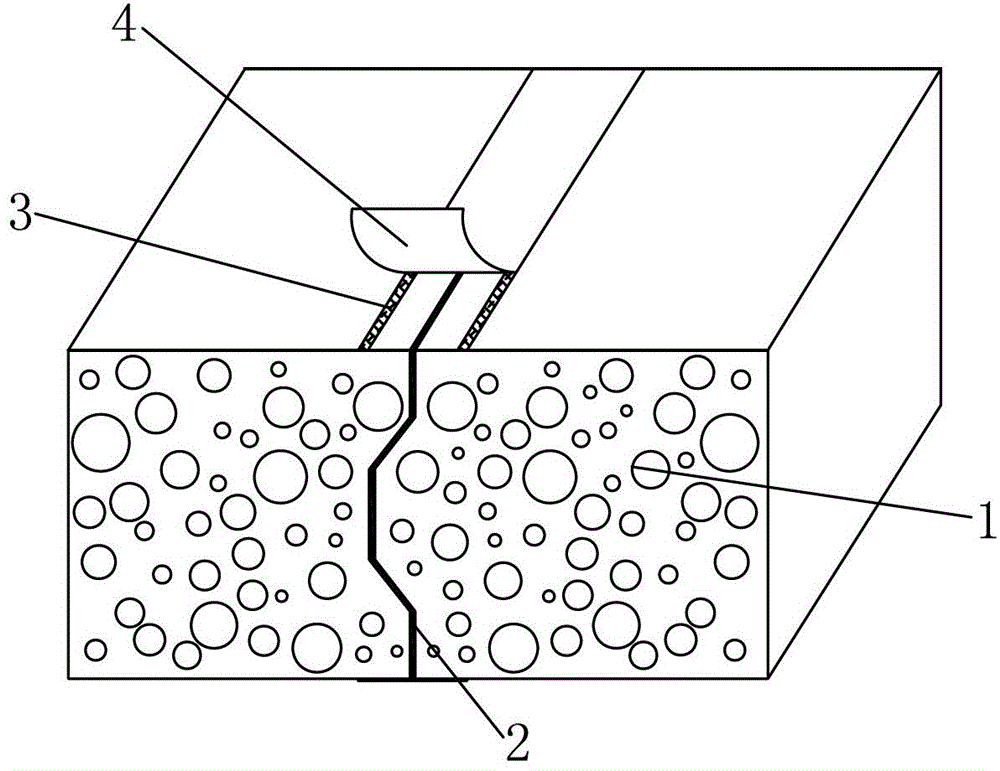

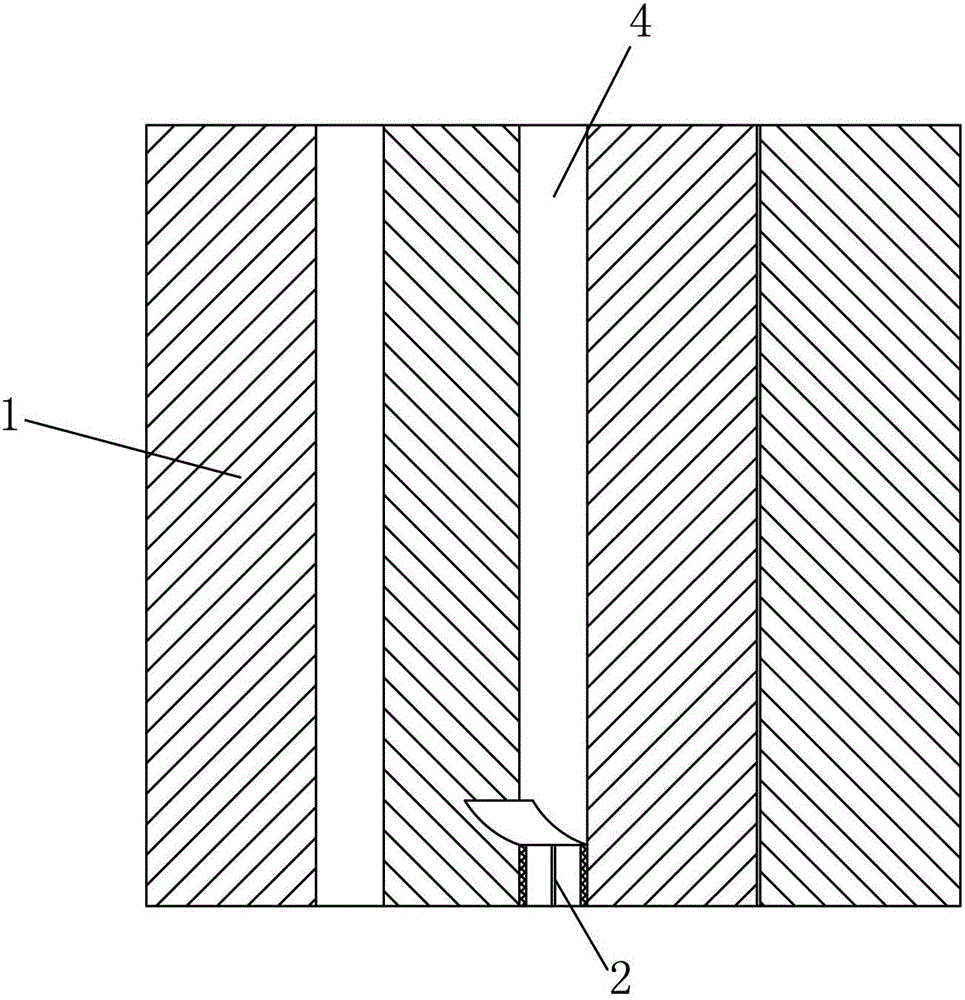

[0026] (1) Select a flat installation surface, and coat the contact between the two lightweight slats 1 with polymer mortar 2. The polymer mortar 2 includes cement, fine sand, EVA rubber powder, PVA, cellulose ether, powder Coal ash, mineral powder and water, the weight ratio of the above components is 100: (100-400): (0-10): (0-4): (0-4): (8-14): (6- 16): (40-65);

[0027] (2) Use the lower wedge roof method to install the strip 1, so that the joint is filled with polymer mortar 2, and scrape the joint with a scraper;

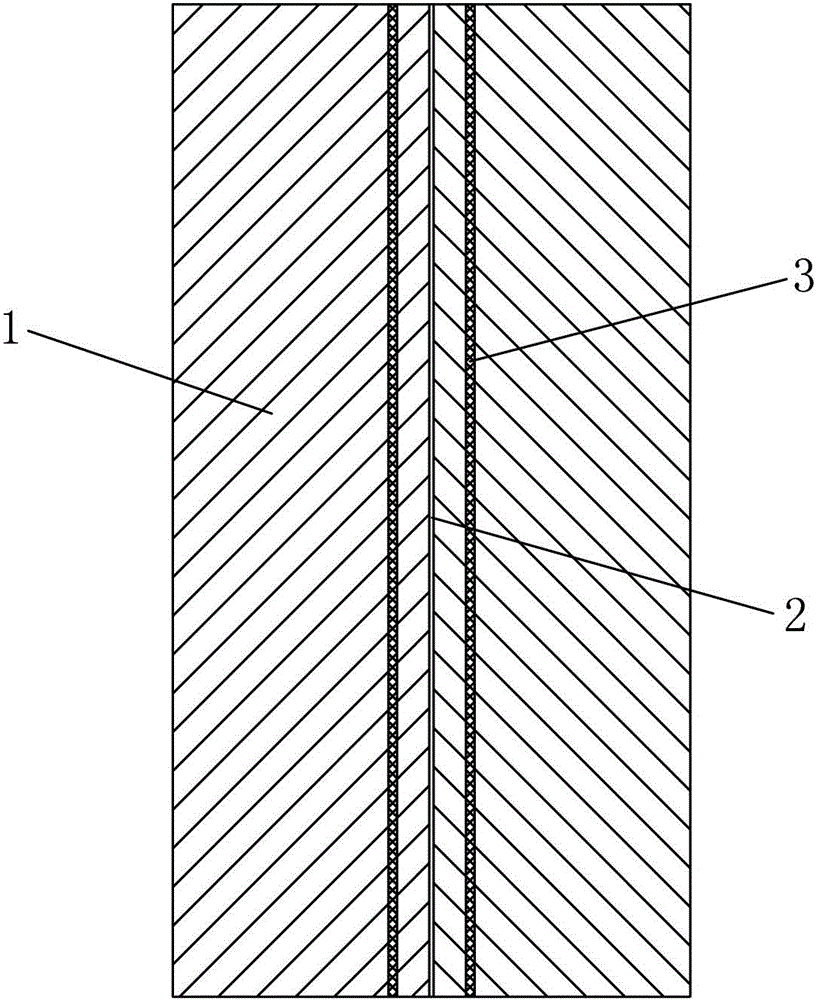

[0028] (3) if figure 1 As shown, draw a line 20 mm along the two ends of the center of the above-mentioned joint, and apply the adhesive 3 symmetrically a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com