Ordinary pressure water jacket furnace of acidic gas field wellhead

A water jacket furnace and gas field technology, applied in water heaters, boreholes/well parts, isolation devices, etc., can solve the problems of inability to adjust pressure, affect the strength and service life of the heating furnace, and weld dead as a whole, so as to achieve convenient heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

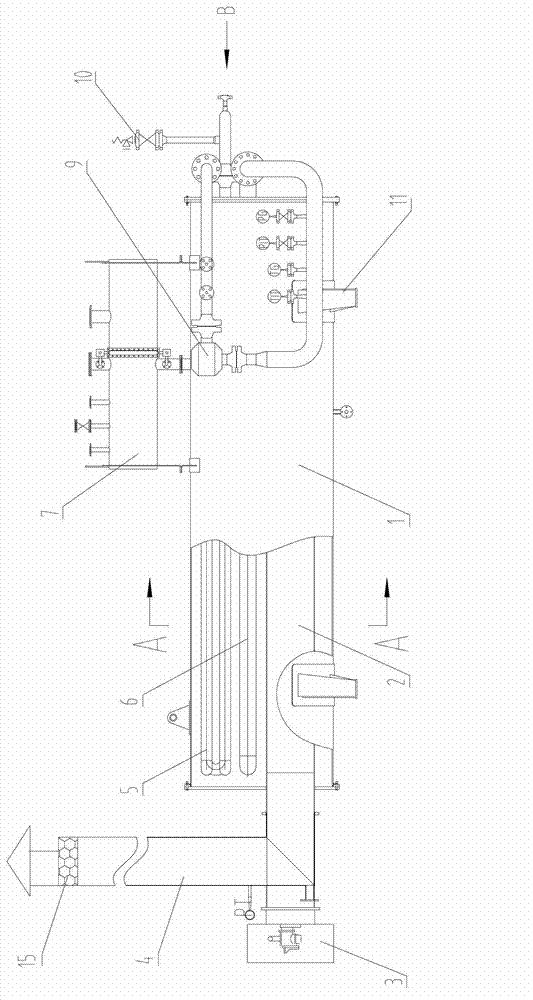

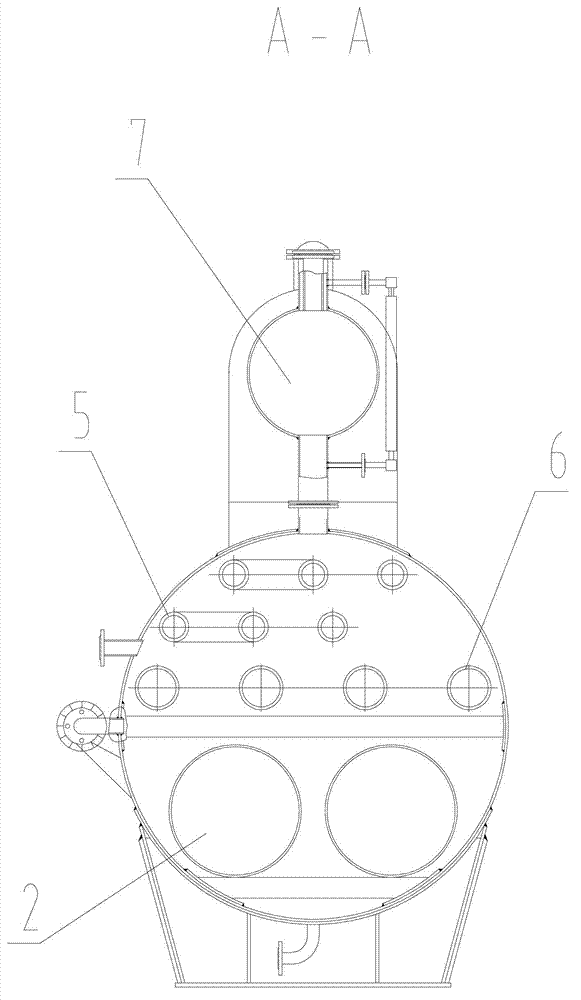

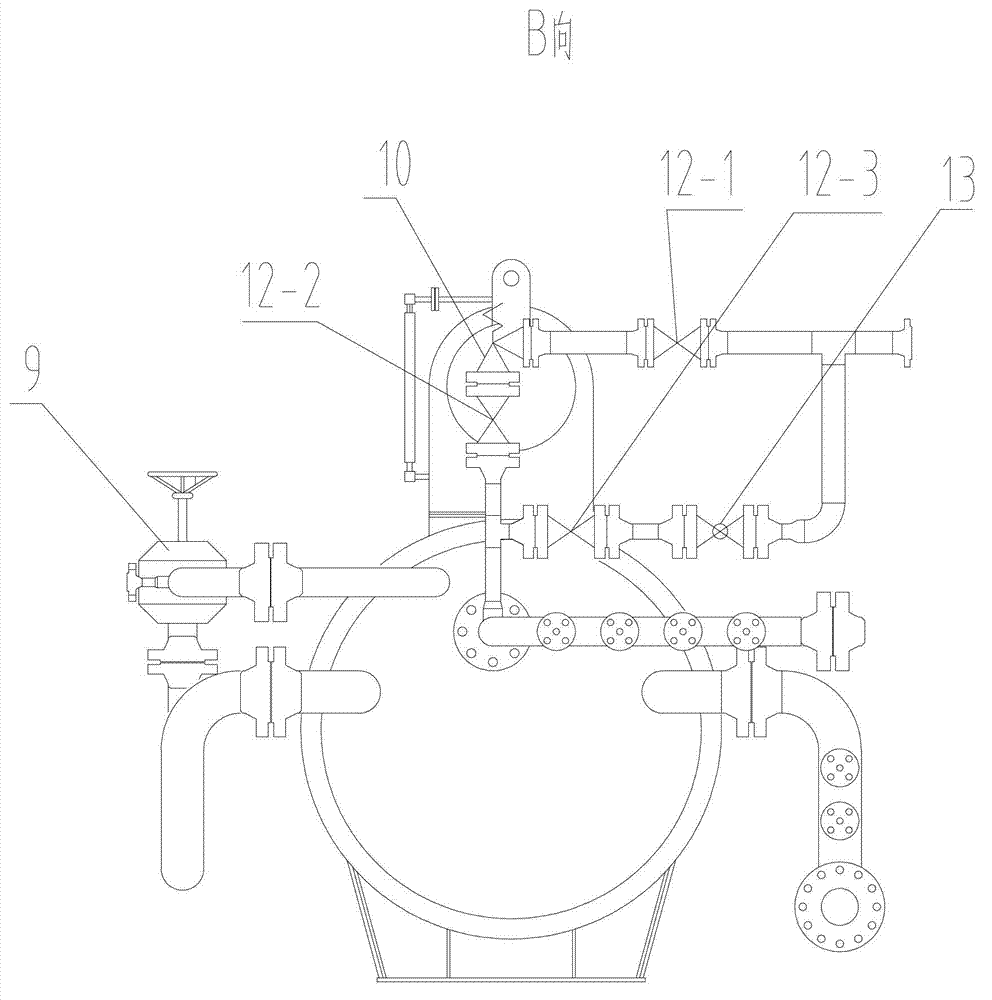

[0017] Such as figure 1 As shown, a sour gas field wellhead atmospheric water jacket furnace has a horizontal shell 1, a fire tube 2 is installed on the lower part of the inner cavity of the shell 1, the fire tube 2 is connected to the flange at one end of the shell 1, and the entrance and exit of the fire tube 2 are installed There are a burner 3 and a chimney 4. A coil device for feeding natural gas is installed on the upper part of the inner cavity of the shell 1. An expansion tank 7 is installed outside the shell 1. The expansion tank 7 communicates with the inner cavity of the shell 1. The inner cavity of the shell 1 The heat transfer medium is installed in the coil, and the coil device is connected to the flange at the other end of the housing 1 . The end of the entrance and exit of the torch 2 stretches out of the housing 1 . The expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com