Coalbed methane gas drainage testing method during combined mining of multiple coalbeds

A technology of combined mining and test methods, applied in mining equipment, earthwork drilling, gas discharge, etc., can solve problems such as coalbed methane extraction that cannot be explained, and achieve the effect of high degree of automation and convenient operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

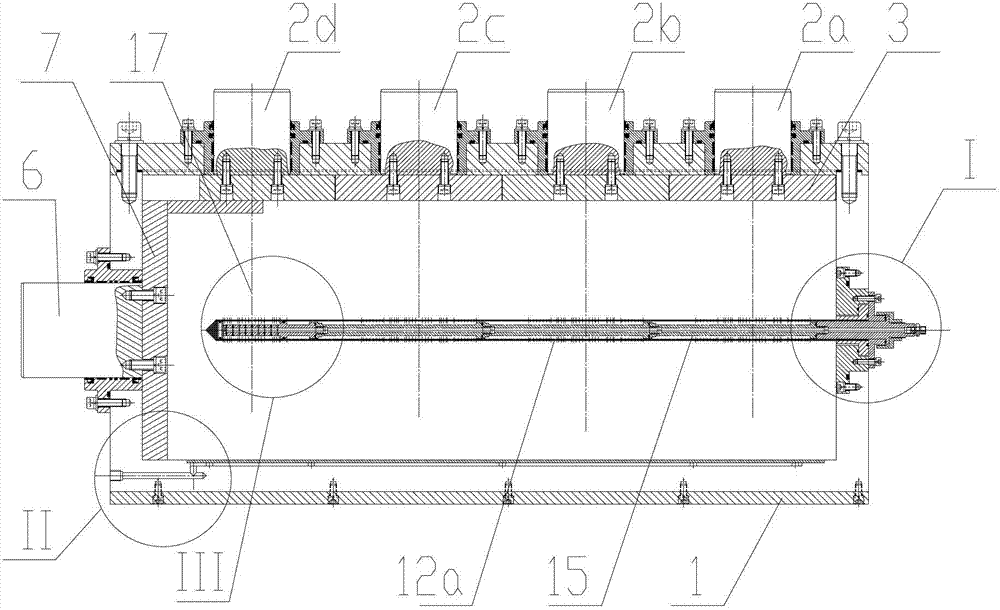

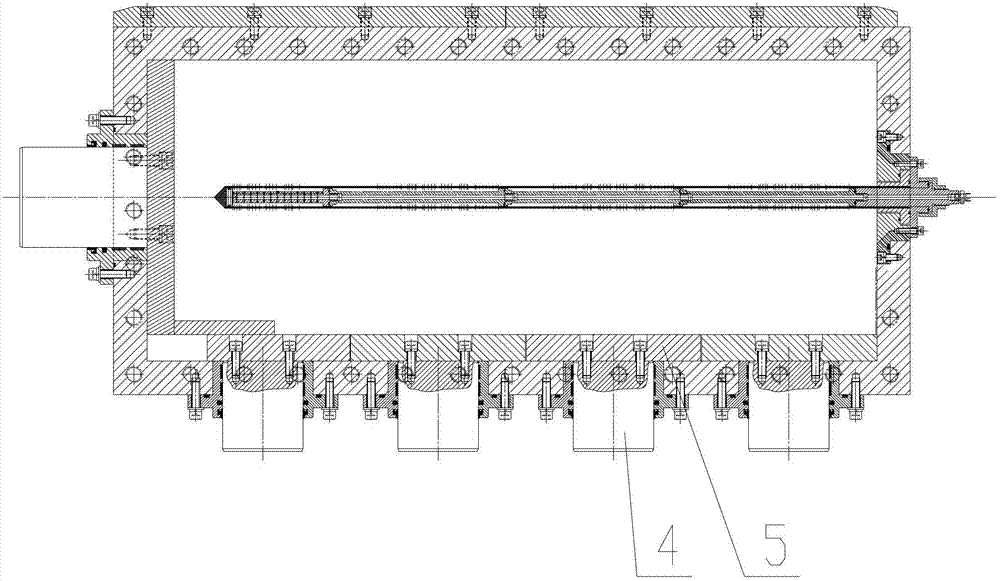

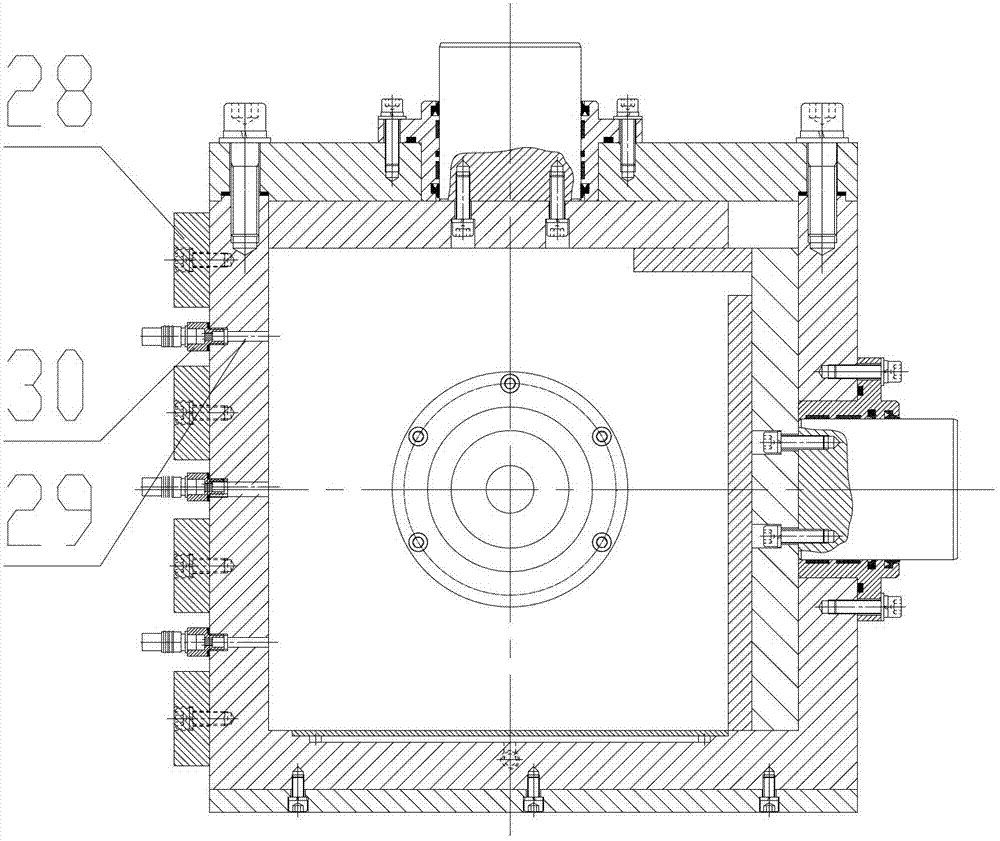

[0085] Such as Figure 1 to Figure 6 As shown, a multi-field coupled coalbed methane mining physical simulation test system includes a test piece box 1, and the upper box plate of the test piece box 1 is sequentially provided with a first Z-direction pressure bar 2a and a second Z-direction pressure bar 2b, the third Z-direction pressure rod 2c and the fourth Z-direction pressure rod 2d, each Z-direction pressure rod is fixed with a Z-direction pressure plate 3, and four Y-direction pressure rods 4 and Y-direction pressure plates 5 are arranged on the right box plate, An X-direction pressing rod 6 and an X-direction pressing plate 7 are arranged on the rear case plate. The Z-direction pressing plate 3 , the Y-direction pressing plate 5 and the X-direction pressing plate 7 are all located in the specimen box 1 .

[0086] The bottom of the test piece box 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com