Hydrostatic system, hydrostatic steering system and hydrostatic pressure-limiting oil replenishing device thereof

An oil replenishment device and hydrostatic technology, applied in fluid pressure actuation devices, fluid steering mechanisms, fluid pressure actuation system components, etc., can solve problems such as oil pressure drop, system damage, oil pressure rise, etc., to improve reliability Effects on Operability and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

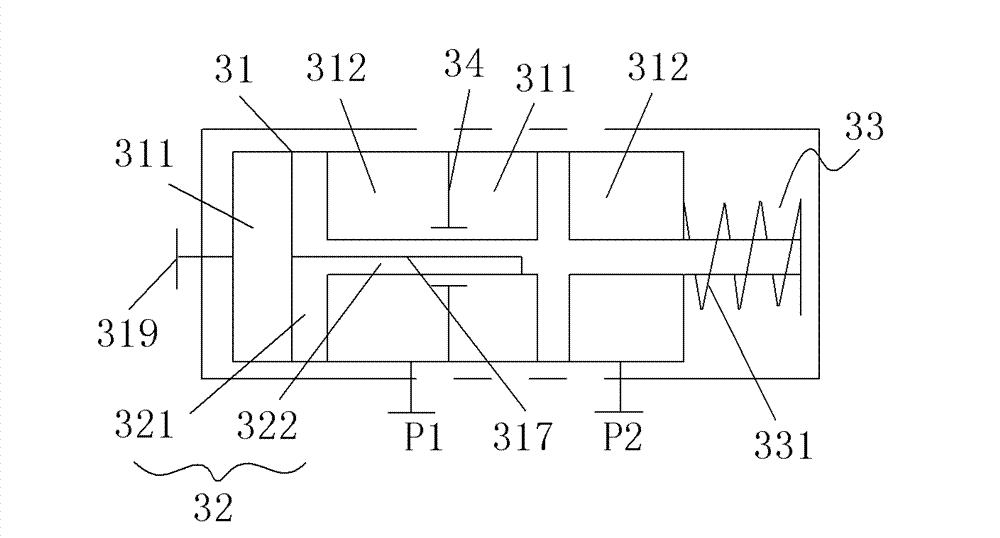

[0063] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

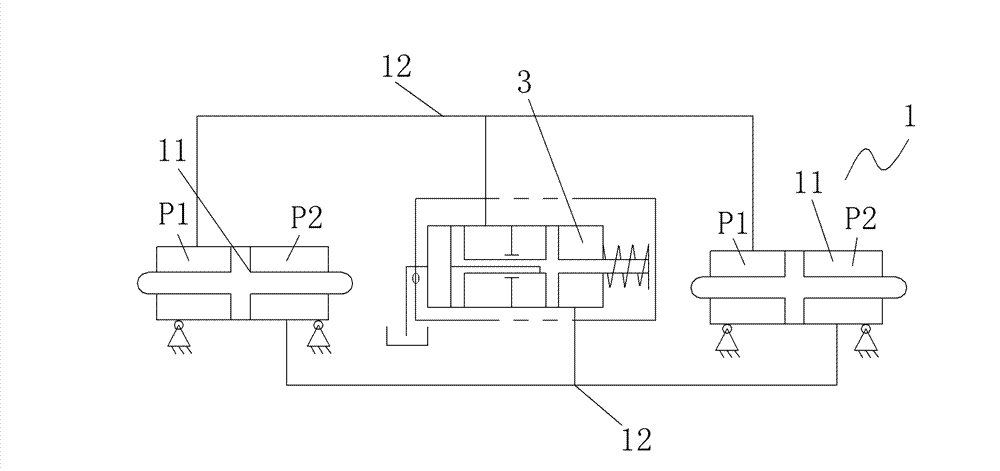

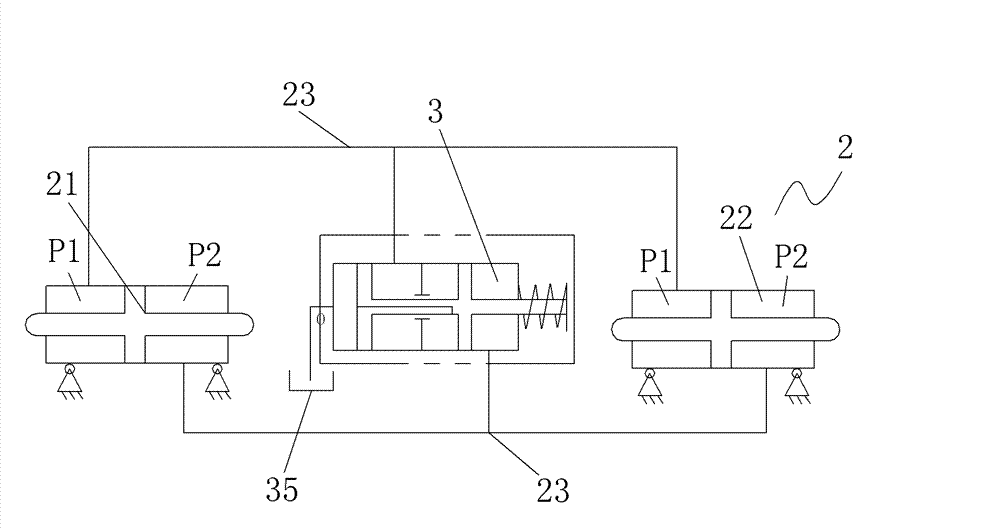

[0064] see figure 1 , figure 1 It is a schematic structural diagram of a hydrostatic system according to an embodiment of the present invention. The hydrostatic system 1 of the present invention comprises a plurality of hydrostatic hydraulic cylinders 11, and the plurality of hydrostatic hydraulic cylinders 11 include active hydrostatic hydraulic cylinders and driven hydrostatic hydraulic cylinders, and the plurality of hydrostatic hydraulic cylinders 11 (due to the principle are the same, so the following two hydrostatic chambers are used as an example to illustrate), the corresponding hydrostatic chambers P1 and P2 are connected respectively, and the hydrostatic system 1 also includes a hydrostatic pressure limiting oil supply device 3, the hydrostatic pressure limiting The oil replenishing device 3 is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com