Efficient temperature stratification heat exchange energy storage water tank with internally arranged phase change thermal storage materials

A phase change heat storage material and temperature stratification technology, which is applied in household heating, household heating, heating methods, etc. Effective heat storage capacity, reducing inlet and outlet disturbances, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

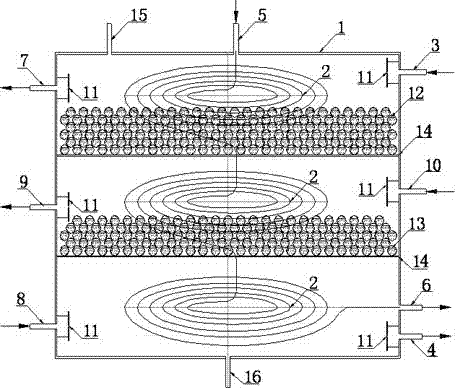

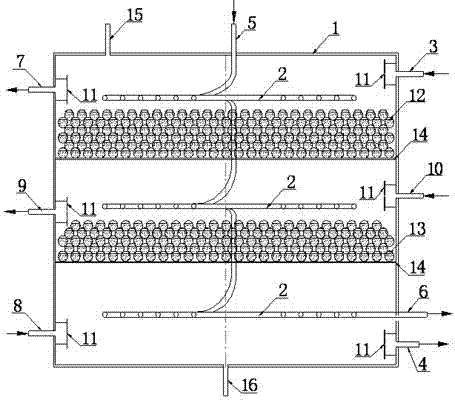

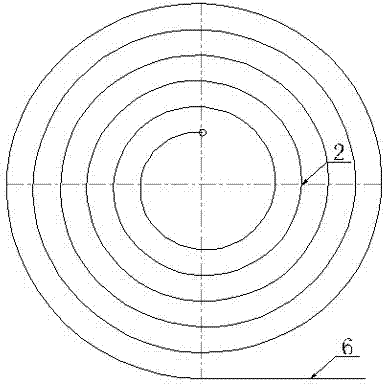

[0010] Such as figure 1 , figure 2 as shown, The present invention is a high-efficiency temperature layered heat exchange energy storage water tank with built-in phase change heat storage materials. The hot water tank is divided into three layers, which are high temperature zone, medium temperature zone and low temperature zone from top to bottom. A baffle plate 11 is respectively arranged at the entrance and exit, and the structure of the baffle plate 11 is as follows: Figure 4 , Figure 5 shown. There is an exhaust valve 15 and a drain valve 16 on the tank. The high-temperature hot water from the heat collector enters the heat exchange coil 2 through the heat exchange coil inlet 5, and in the hot water storage tank 1, it is connected with the upper and middle heat storage tanks in sequence. The medium, that is, water and high-temperature phase-change heat storage bulbs 12 and medium-temperature phase-change heat storage bulbs 13 perform layered heat exchange, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com