Wet sand oven-dry system

A drying system and wet sand technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of environmental pollution, generate more dust, unfavorable equipment use, etc., to achieve full and reasonable utilization, full dust, fully absorbed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

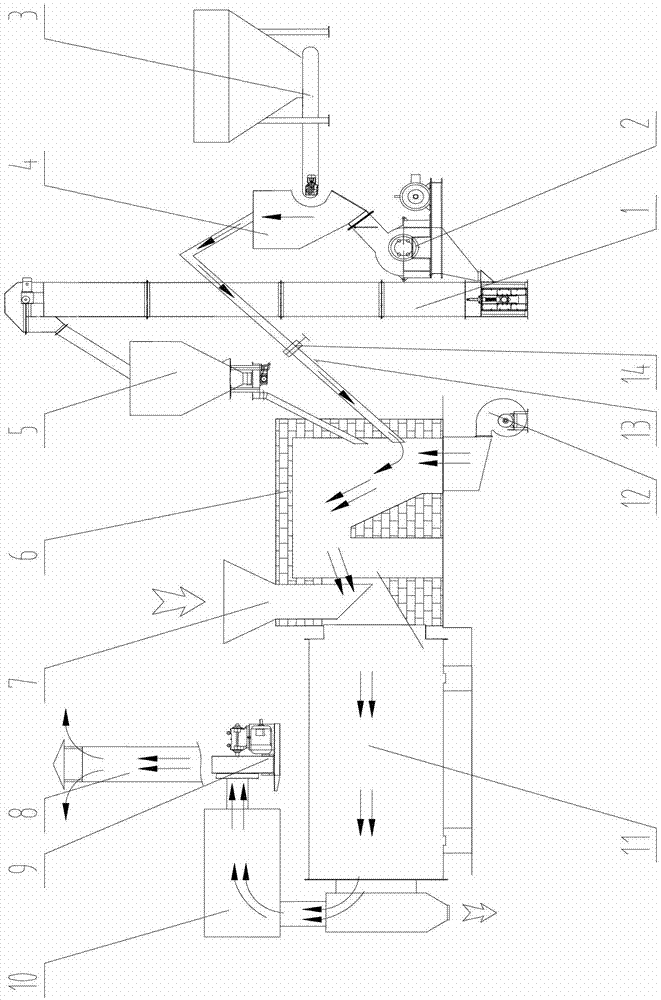

[0020] Such as figure 1 As shown, the wet sand drying system of the present invention comprises: a coal feeding hopper 4, a fluidized fluidized furnace 6, a sand feeding pipe 7, a dryer 11, an induced draft fan 9, an exhaust pipe 13 and a blower 12; The feed port, the air exhaust port and the feed port, the induced draft fan 9 is connected with the air discharge port of the dryer 11, the sand inlet pipe 7 is connected with the feed port of the dryer 11, and the fluidized fluidized furnace 6 is provided with an air inlet and an air outlet , the air inlet of fluidized fluidized furnace 6 is connected with blower 12, and when the system works, the air volume of induced draft fan 9 is greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com