Transducer capable of being directly applied to various ultrasonic flow meters

An ultrasonic and transducer technology, applied in the field of transducers, can solve problems such as poor anti-corrosion, anti-impurity and anti-fouling effects, maintenance and replacement shutdown processing, failure of measurement equipment, etc., to achieve stable and reliable sampling signals, The effects of excellent pressure-bearing performance and durability, and excellent acoustic-electric matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

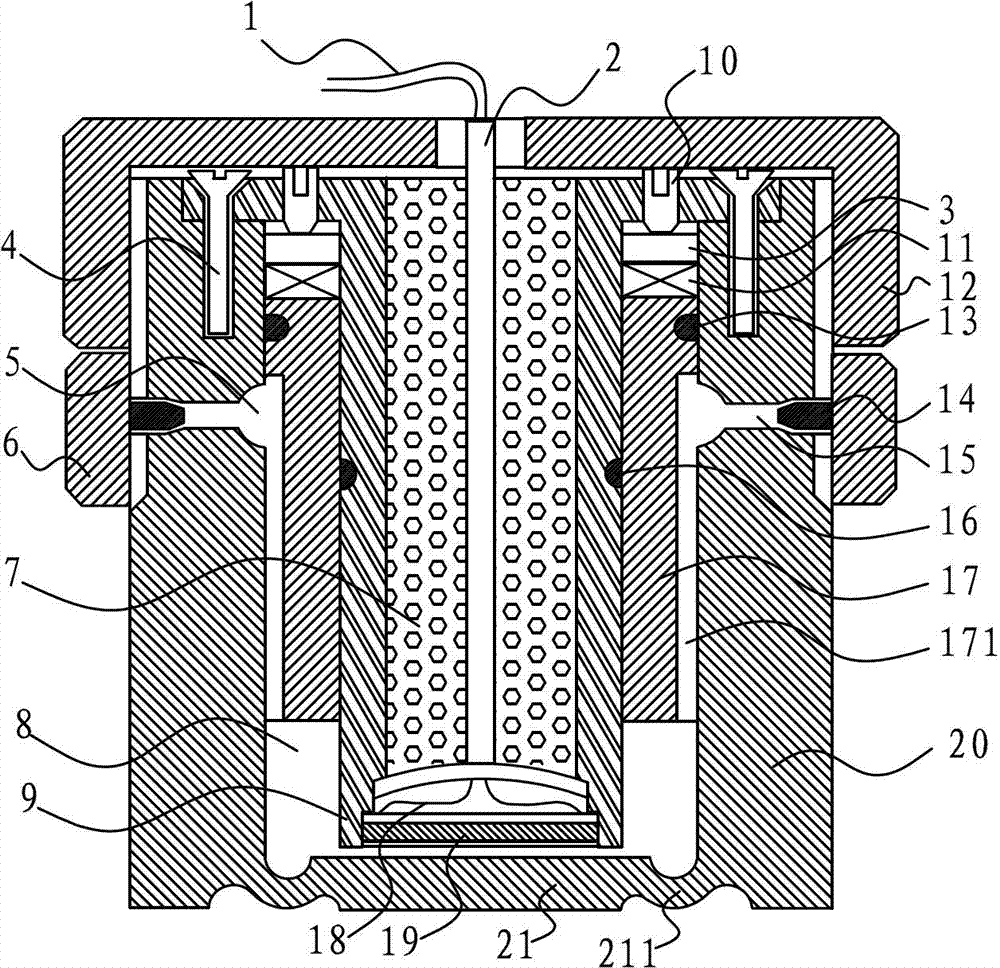

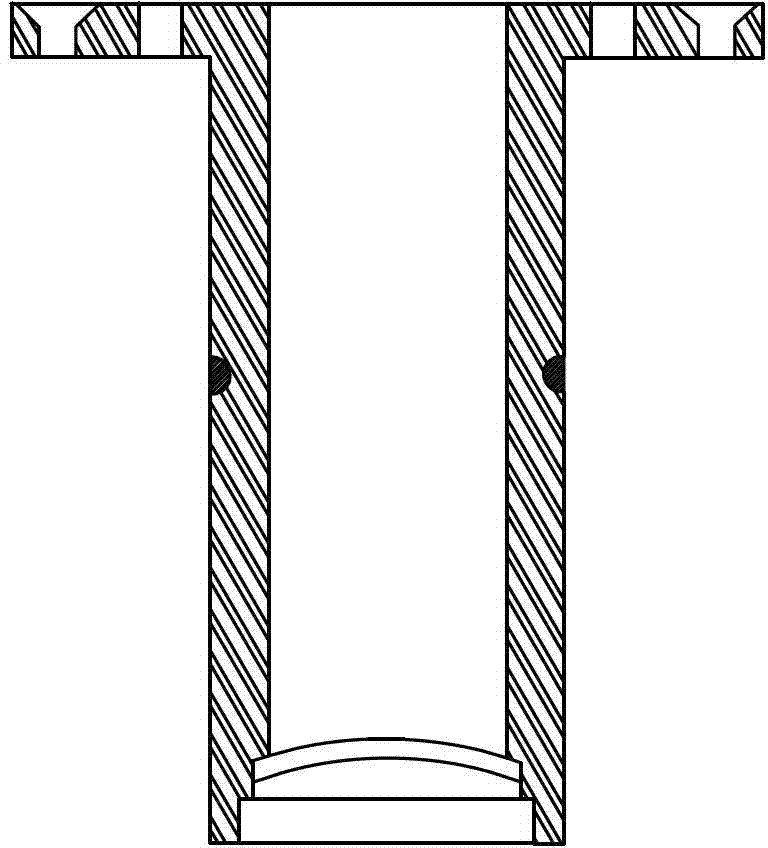

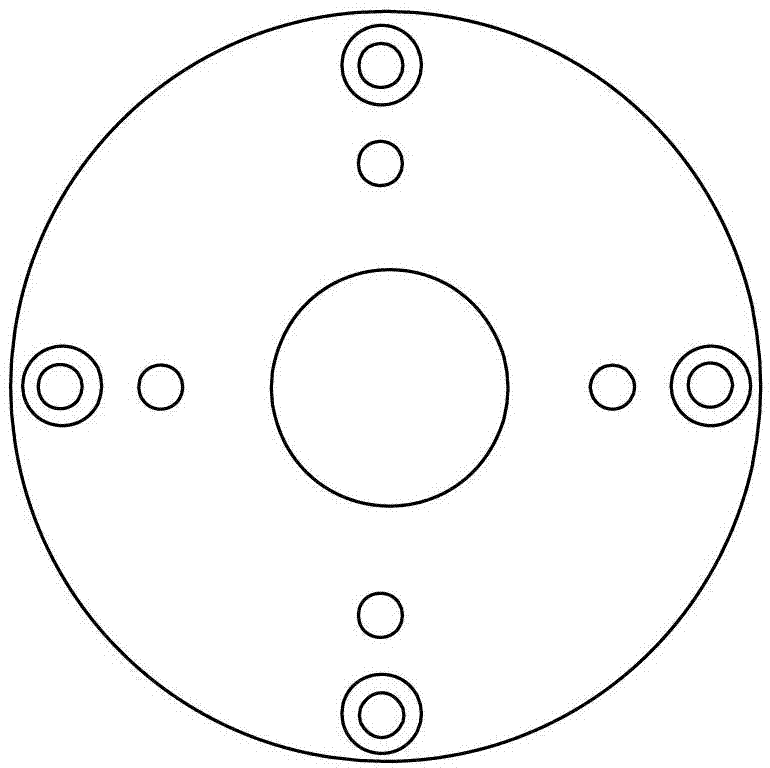

[0026] Embodiments of the present invention will be described below with reference to the drawings. In this specification, in order to simplify the description, words used to describe the positional and directional relationship between corresponding components, such as upper, lower end, inner, outer, top and bottom, only refer to the positional relationship and direction in the drawings.

[0027] Such as Figure 1 to Figure 5 The shown transducer directly applied to a variety of ultrasonic flowmeters includes: a piezoelectric ceramic sheet support 9 for fixing the piezoelectric ceramic sheet 19; Part 17; a hard shell 20 for accommodating the piezoelectric ceramic sheet 19, the piezoelectric ceramic sheet support 9 and the cylindrical seal 17; the piezoelectric ceramic sheet support 9 is cylindrical, and its top is a fixed end , and the fixed end is provided with a through hole for the fixing screw 4 to pass through, and a threaded through hole for matching with the adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com