Laser interference lithography system

A technology of laser interference lithography and lasers, which is applied in the field of laser interference lithography systems, can solve problems such as difficult to realize large-area high-precision grating production, and achieve the effects of good graphic quality, high graphic locking accuracy, and high graphic locking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

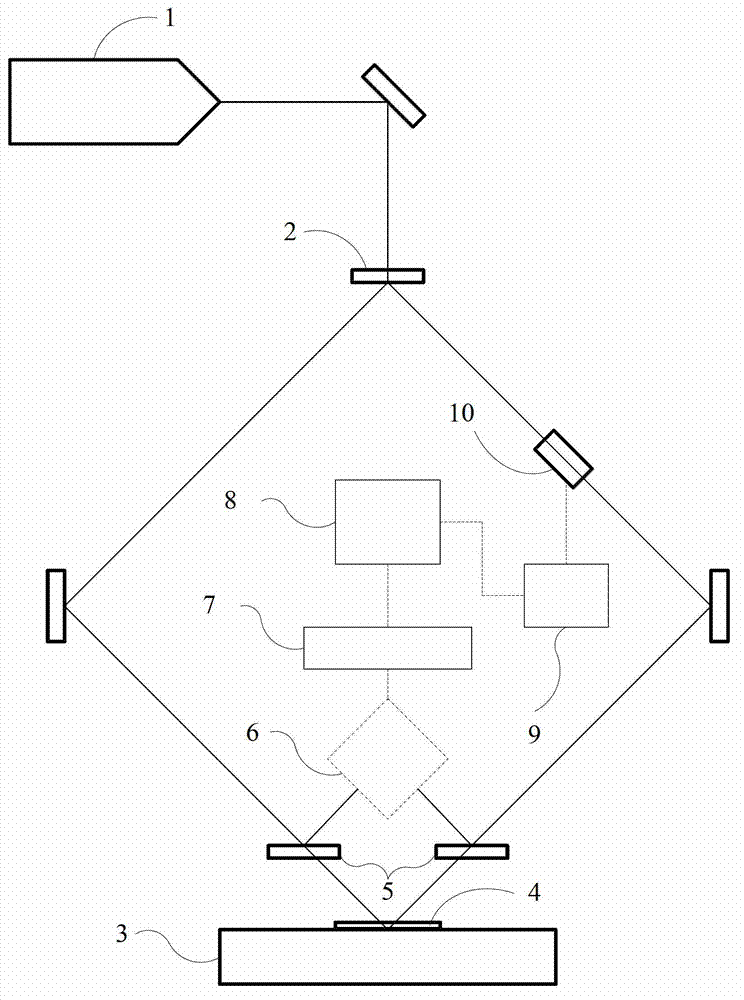

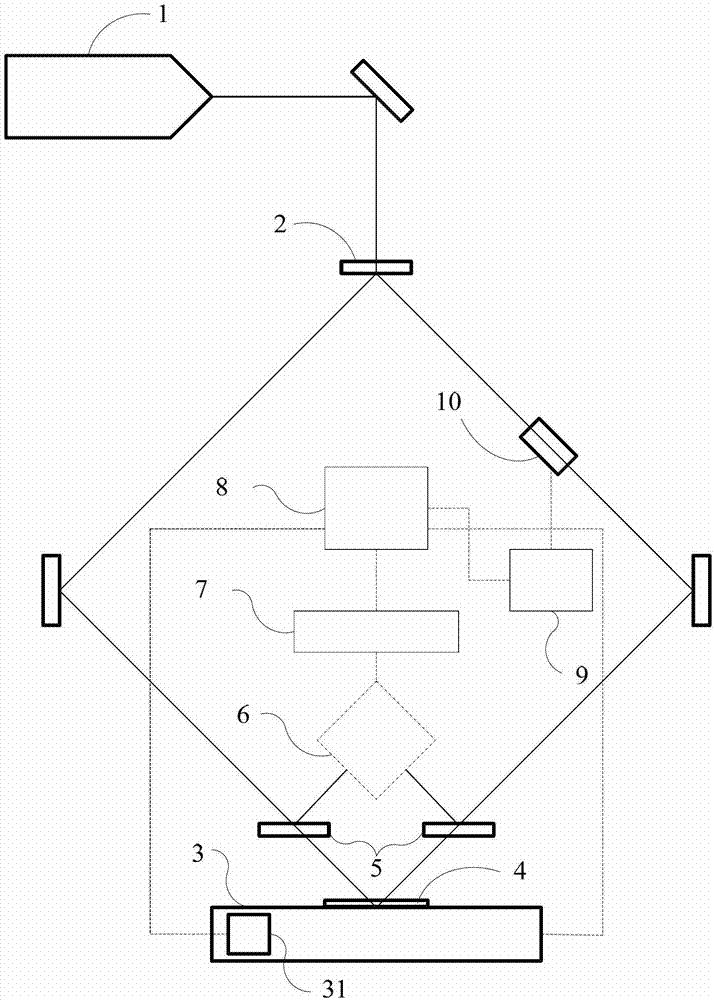

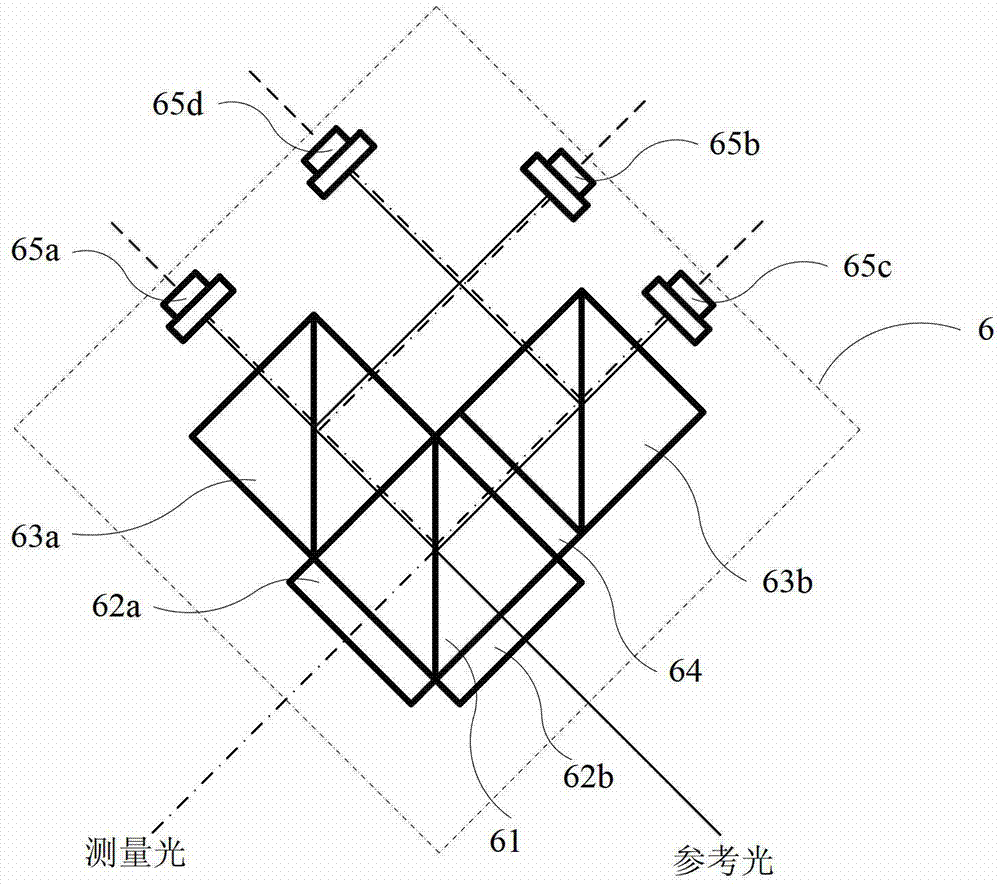

[0038] Please refer to figure 1 , figure 1 It is a schematic diagram of the first laser interference lithography system of the present invention. Such as figure 1 As shown, the interference lithography system is composed of a laser 1, a mirror, a beam splitter 2, a substrate table 3, and a substrate 4; the laser light emitted by the laser 1 is divided into two interference beams after passing through the mirror and the beam splitter 2. The interfering light beam realizes combined light interference on the substrate 4 carried by the substrate table 3 through the mirror, and the interference pattern realizes pattern recording and transfer through the exposure of the substrate; the laser interference lithography system also includes a pattern locking system, which includes two beams A sampler 5, a homodyne phase meter 6, an electronic signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com