Ion source uniform air supply structure device

An ion source and gas supply technology, applied in electrical components, discharge tubes, circuits, etc., can solve problems such as failure of injection beam injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

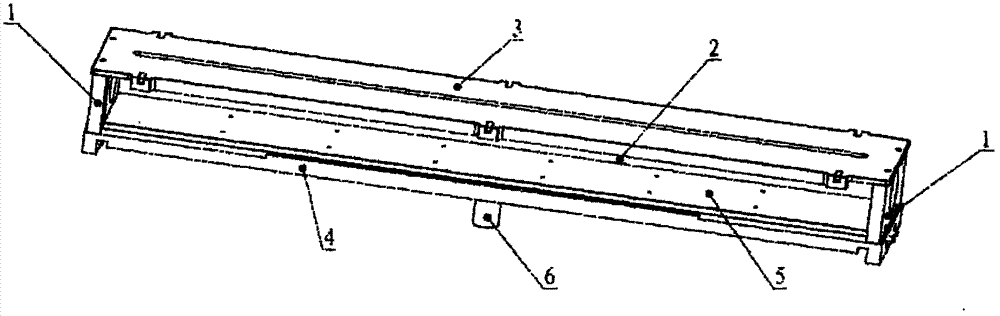

[0015] The present invention will be further introduced below in conjunction with the accompanying drawings, but not as a limitation to the invention.

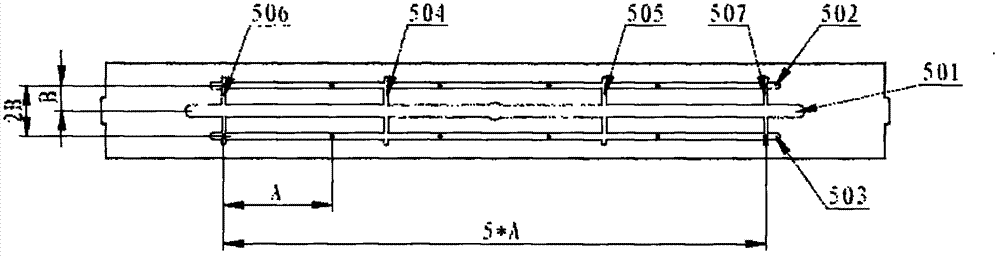

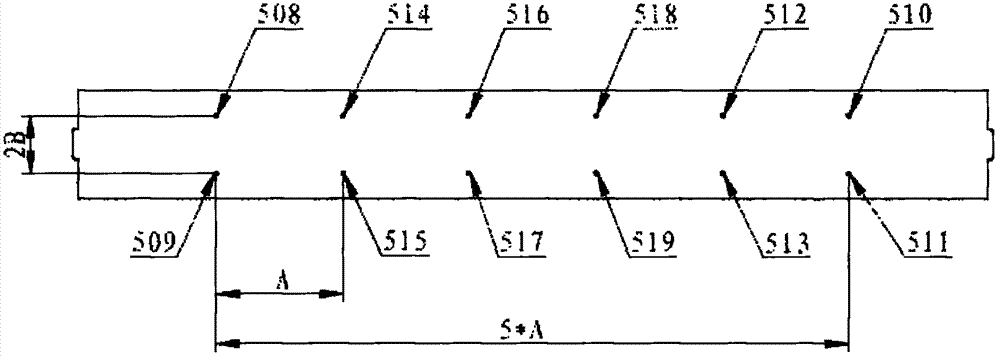

[0016] The gas sent in flows into between the gas supply bottom plate (4) and the gas supply cover plate (5) through the gas supply pipe head (6), and the gas supply cover plate (5) is provided with the gas supply pipeline (501) to the gas supply pipeline (507). The uniform flow of gas is realized by utilizing the geometric symmetry of the gas supply pipeline (501) to the gas supply pipeline (507). At this time, uniform gas supply holes (508) to gas supply holes (519) are set on the secondary gas supply pipeline (502) and secondary gas supply pipeline (503) (they communicate with the arc chamber), and the gas flows along the gas supply hole (508) to the gas supply hole (519). The air supply hole (519) flows uniformly into the arc chamber cavity, meeting the requirement of uniform ionization of gas molecules.

[0017] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com