Process for manufacturing a casting made of ductile cast iron for a high-voltage insulator fitting

A technology for fastening parts and insulators, applied in insulators, electrical components, suspension/strain insulators, etc., to solve problems such as poor tensile strength and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

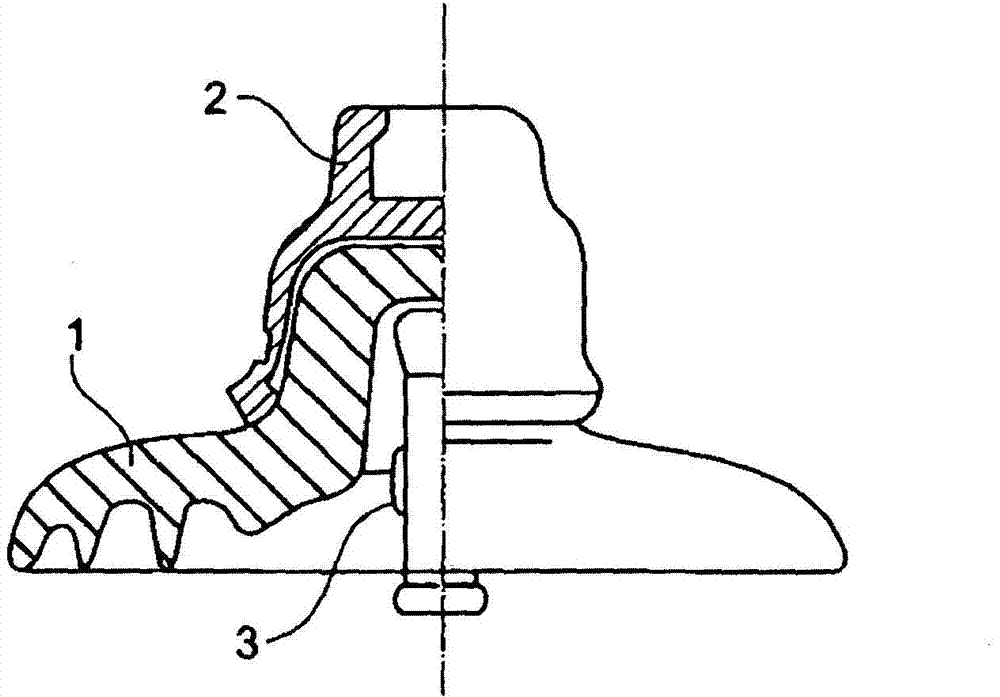

[0017] exist figure 1 Among them, the capped pin-shaped high-voltage insulator comprises an insulating part 1 made of glass, on which a cap 2 cast in cast iron is fastened on the upper part and a needle 3 is fastened on the lower part.

[0018] The cap 2 is obtained by casting ductile cast iron with a controlled chemical composition.

[0019] The chemical elements normally present in ductile cast iron affect its tensile strength properties and its low temperature impact strength properties according to their proportions in the composition. Silicon is an element that is most important both for the tensile strength and the transition temperature from the ductile state to the brittle state. Manganese and phosphorus affect cold toughness (ténacité).

[0020] According to the invention, the ductile cast iron used for the manufacture of the insulator cap is a cast iron whose composition is such that the cast contains the following chemical composition in the proportions: 3.2%-3.7%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com