Bio-enzyme hydrogel taking porous calcium carbonate as carrier and preparation method of bio-enzyme hydrogel

A technology of porous calcium carbonate and hydrogel, which is applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, liquid delivery, etc. It can solve the problems of fast biological enzyme release rate and inability to meet clinical applications. , to achieve good air permeability, increase drug loading, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] formula:

[0029] The content in weight percentage is: 0.01% of lysozyme; 15% of porous calcium carbonate; 1% of chitosan; 2% of gelatin; 15% of glycerin; 20% of ethanol;

[0030] (1) Pass carbon dioxide gas into the calcium hydroxide slurry with a weight content of 15% for carbonization. During the carbonization process, add ammonium persulfate solution and hydrazine hydrate solution independently at the same time. When the carbonization reaches the pH of the slurry When it is 10, stop adding ammonium persulfate solution and hydrazine hydrate solution in the slurry, continue carbon dioxide gas to carry out carbonization, until pH is 7, finish carbonization;

[0031] The mass percentage concentration of described ammonium persulfate solution is 20%;

[0032] The mass percentage concentration of described hydrazine hydrate solution is 30%;

[0033] The add-on of described ammonium persulfate is 3% of calcium hydroxide dry weight;

[0034] The add-on of described hydra...

Embodiment 2

[0042] formula:

[0043] The weight percent content is: 3% lysostaphin; 20% porous calcium carbonate; 10% chitosan; 2% gelatin; 15% glycerin; 20% ethanol;

[0044] Adopt the porous calcium carbonate of embodiment 1.

[0045] The method for preparing the biological enzyme hydrogel with porous calcium carbonate as the carrier is the same as in Example 1.

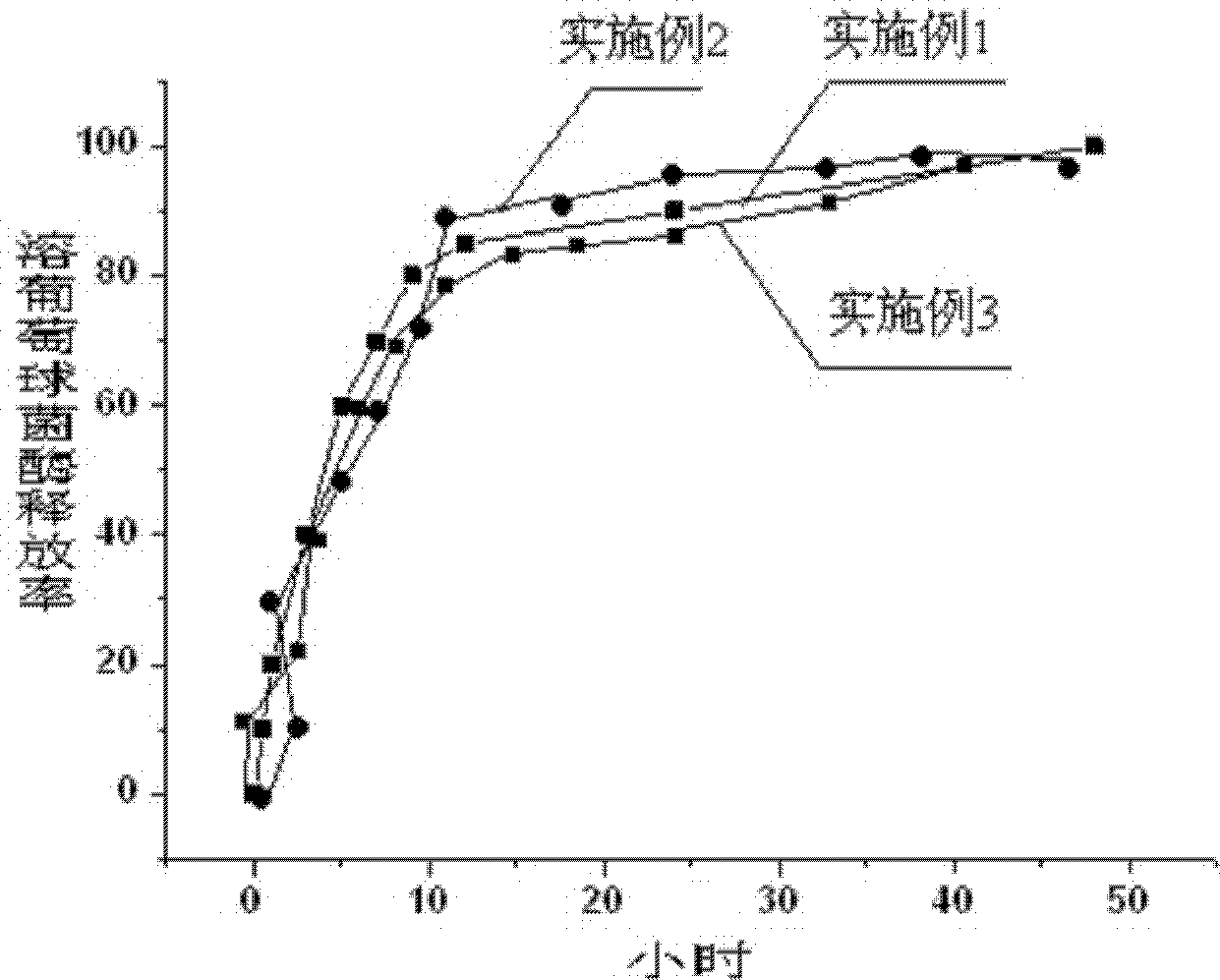

[0046] Detection method is with embodiment 1, and the results are shown in figure 1 .

Embodiment 3

[0048] formula:

[0049] The weight percentage content is: lysozyme 0.5%; lysostaphin 0.1%, porous calcium carbonate 17%; chitosan 5%; gelatin 2%; glycerin 12%; ethanol 17%; acetic acid 1%, water balance

[0050] Others are the same as embodiment 1, and the test results are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com