Landscape engineering machinery connecting rod precision forging method

A construction machinery and precision forging technology, which is applied in the field of precision forging of garden engineering machinery connecting rods, can solve problems such as poor consistency, large material consumption, and rapid temperature loss, and achieve the effects of improving product mechanical properties, low labor intensity, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

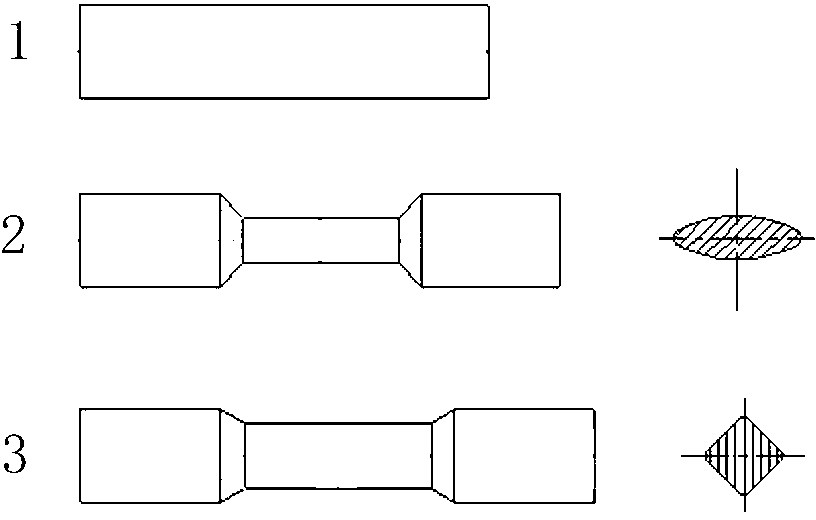

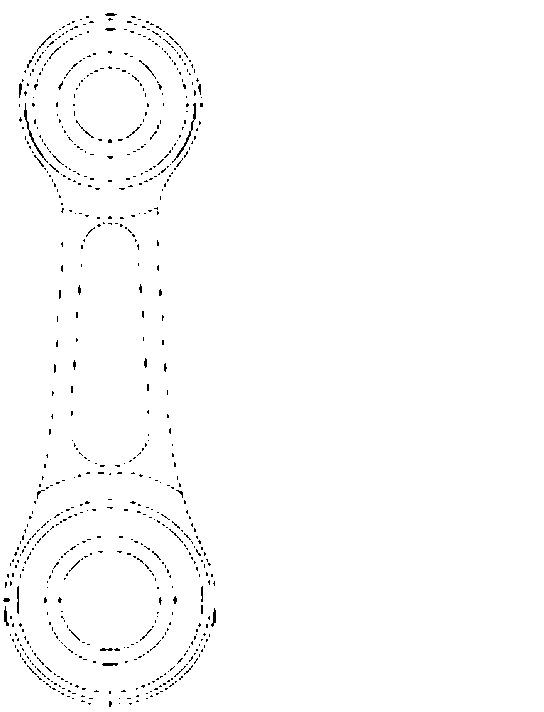

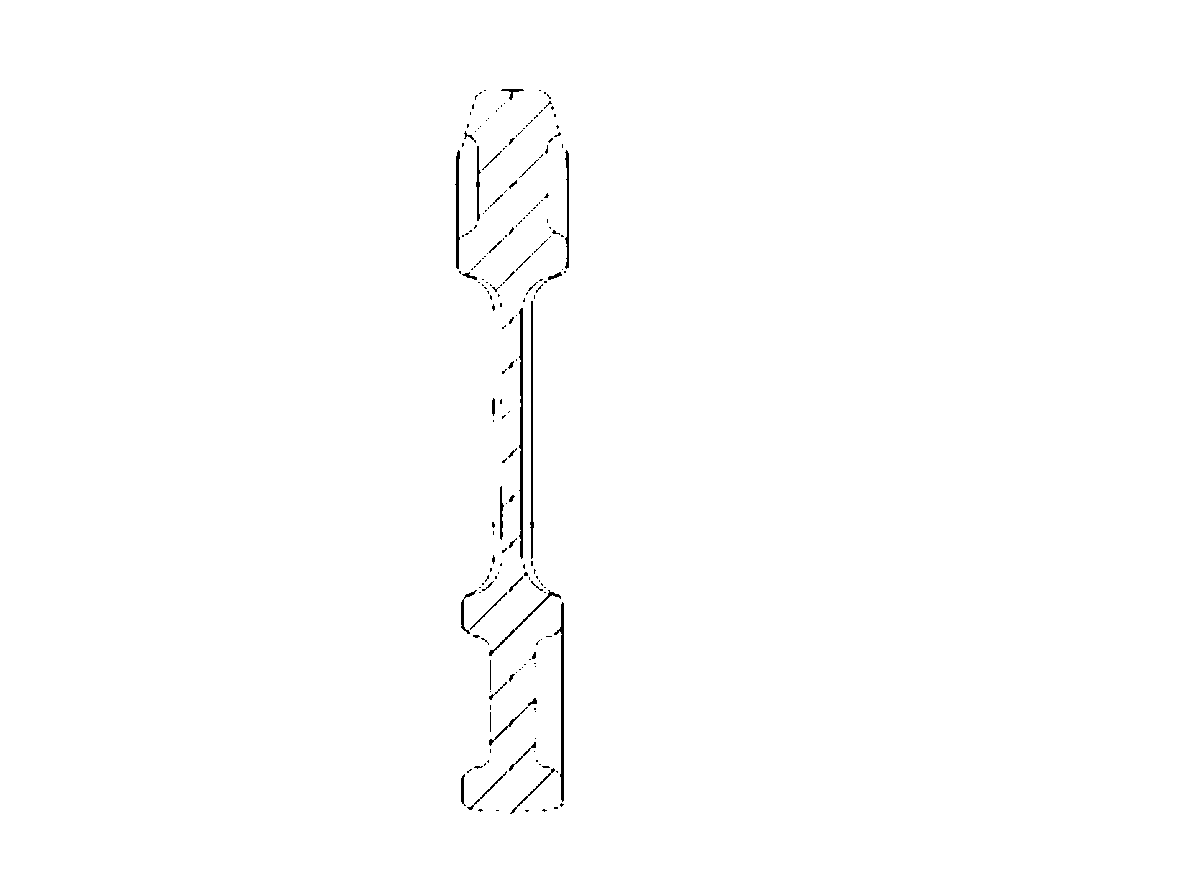

[0010] Such as Figure 1-3 As shown, a precision forging method for connecting rods of garden engineering machinery includes heating, roll forging blanks, forging forming, trimming, grinding burrs, shot blasting, and fine pressing processes. The roll forging blanks adopts two-stage roll forging and heating The latter bar is formed by two roll forging rolls. The first roll forging billet will heat the bar 1 from a cylindrical bar to preform an elliptical cross section of the billet 2, and the second roll forging billet will The cross-section is formed by an elliptical cylinder into a square blank 3, and the length of the blank increases after the second roll forging; the volume distribution of the material used in each part of the blank is ensured by the two-stage roll forging die groove, after the roll forging and forging forming The product is shot blasted first, then volumetric cold precision pressing is used to control the dimensional accuracy. The thickness of the flash is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com