A device and method for testing tool flipping positioning accuracy in a tool magazine

A technology for positioning accuracy and cutting tools, applied in the field of CNC machine tools, can solve the problems that the degree of influence cannot be directly determined, and there is no positioning accuracy of tool turnover, and achieves the effects of novel testing methods, high resolution, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The device for testing the dynamic characteristics of the normal joint surface will be further described in detail below in combination with the working principle and the structural drawings.

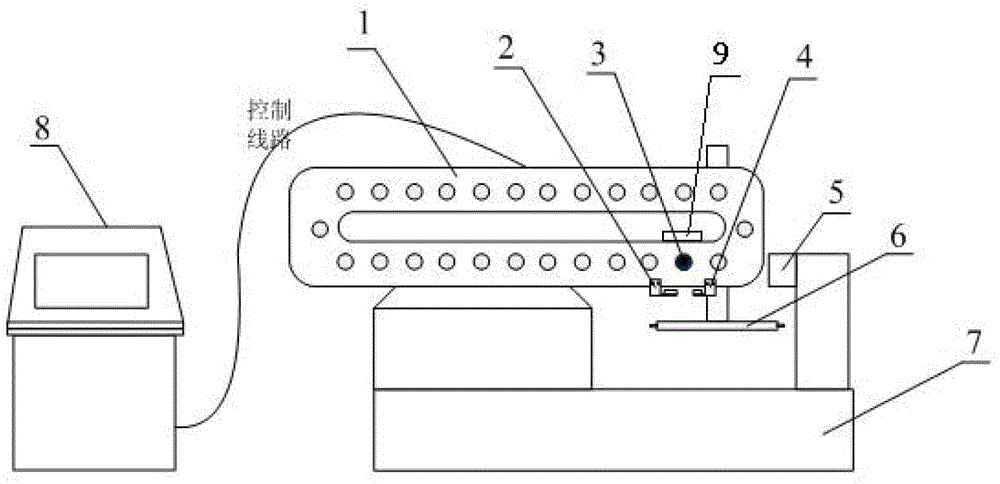

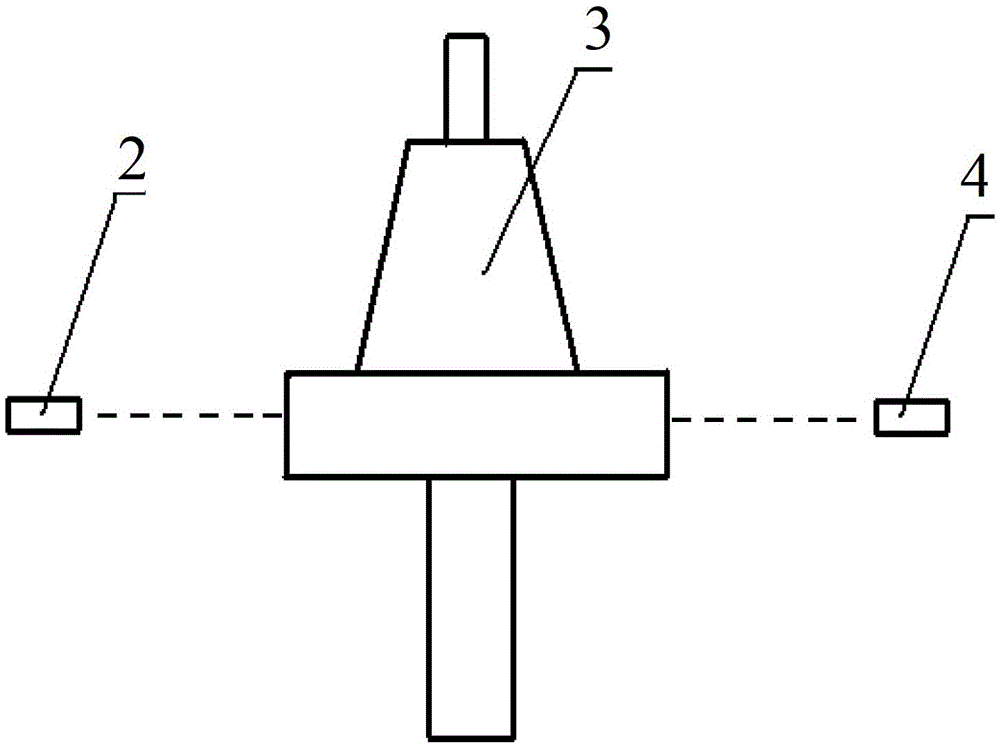

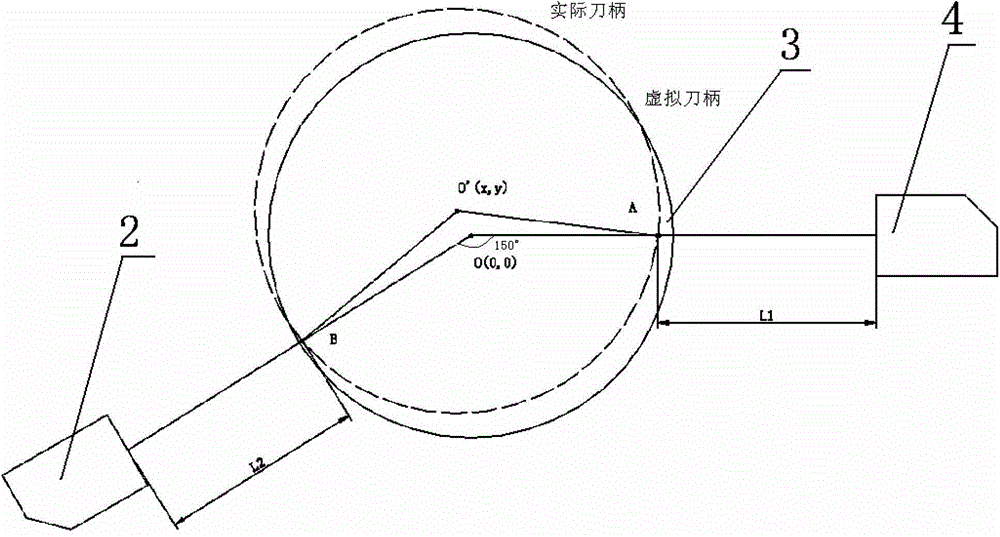

[0022] The device of the present invention includes a chain tool magazine 1 and an automatic tool changer 6, a laser displacement sensor A2, a laser displacement sensor B4, a tool 3, a cylinder 9, an installation platform 7, a control cabinet 8, a virtual spindle 5, a data acquisition card and a PC . The basic idea of the present invention is to use two laser displacement sensors A2 and laser displacement sensor B4 to respectively detect the position of the angle of 150° between the direction of the oblique line and the horizontal direction after the cutting tool 3 is overturned, such as image 3 and the displacement in the horizontal direction, and record the distance offset between the tool handle position of tool 3 and the laser displacement sensor A2 and the laser displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com