Electric tricycle rear axle assembly

A technology for electric tricycles and rear axles, which is applied to braking components, vehicle parts, axles, etc., can solve the problems of reduced service life of bearings, difficult replacement, uneven gaps, etc., and achieves long service life, good braking effect, Even gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

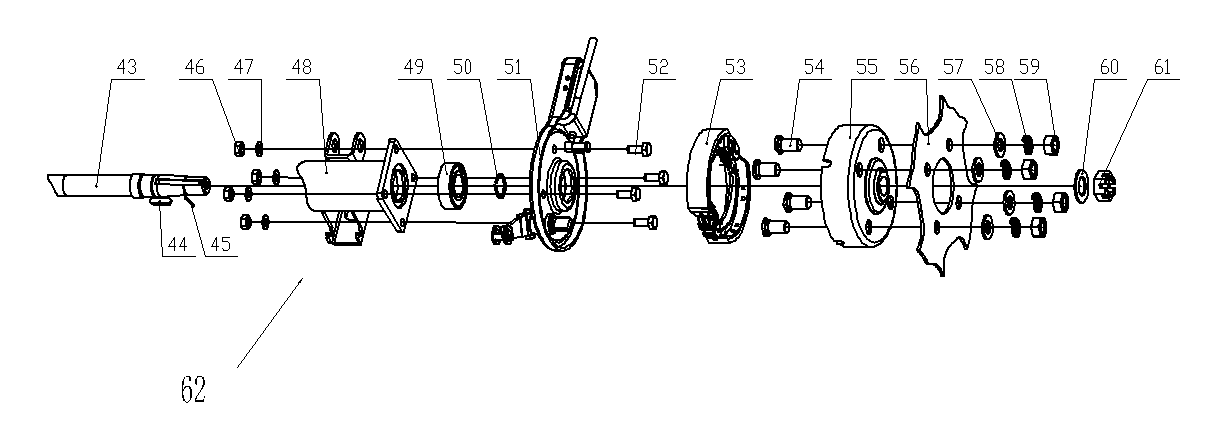

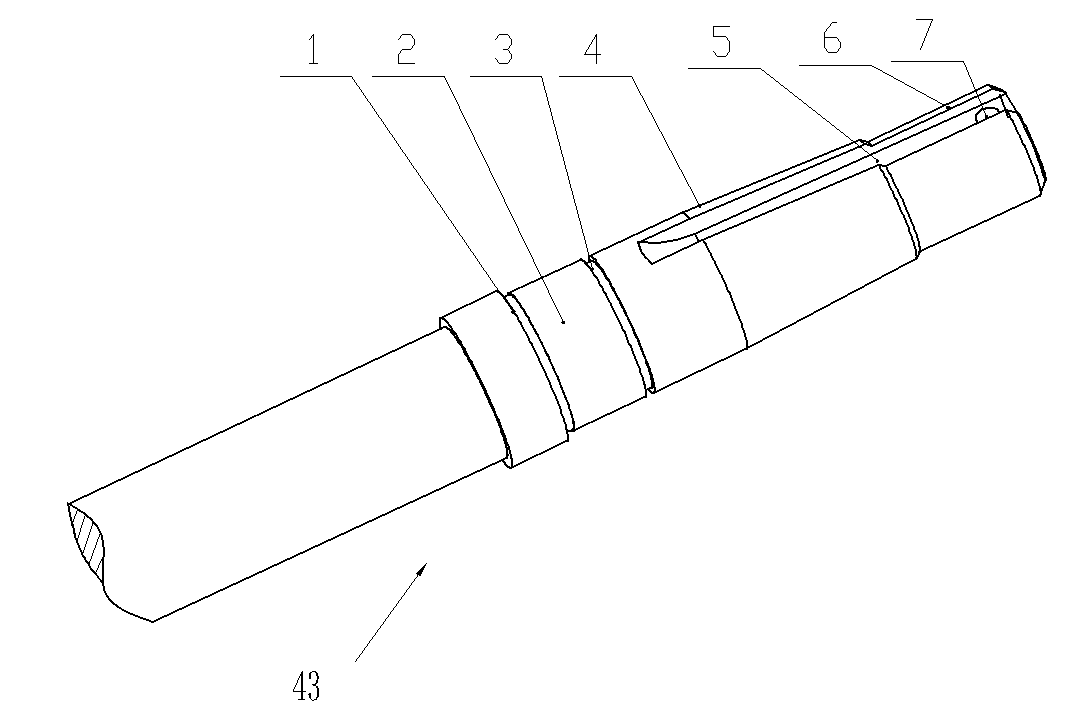

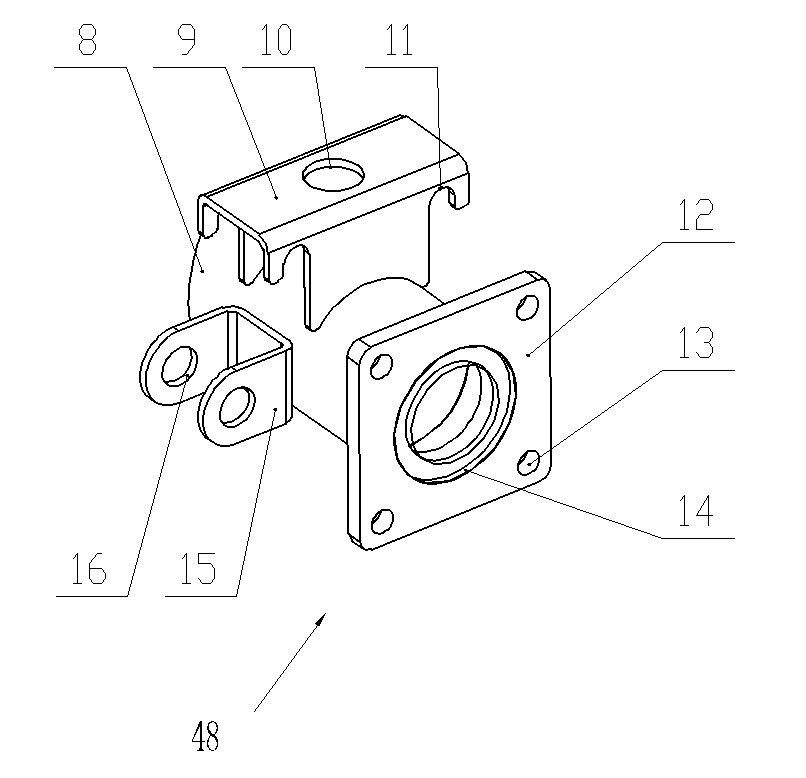

[0033] see figure 1 And other each view, electric tricycle rear axle assembly, it is made up of drive axle shaft 43, rear axle tube assembly 48, bearing 49, brake box assembly 51, shoe block group 53, wheel hub 55 and rim 56, in drive axle shaft 43 A bearing 49 is set on the bearing mating surface 2, and the bearing 49 is installed in the flange bearing groove 14 of the rear axle tube assembly 48 and the brake box bearing groove 28 of the brake box assembly 51, and the half shaft keyway 5 of the driving half shaft 43 and the hub The hub keyway 38 of 55 connects the driving half drive 43 and the wheel hub 55 as a whole through the flat key 44; the wheel hub taper fitting surface 4 of the driving half shaft 43 is matched with the driving half shaft taper fitting surface 37 of the wheel hub 55; In the brake box fixing hole 13 on the flange 12 of the assembly 48 and in the flange fixing hole 24 on the brake box 17 of the brake box assembly 51, the brake box assembly 51 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com