Anode refining furnace

A refining furnace and anode technology, applied in the field of feeding equipment, can solve problems such as flue gas spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

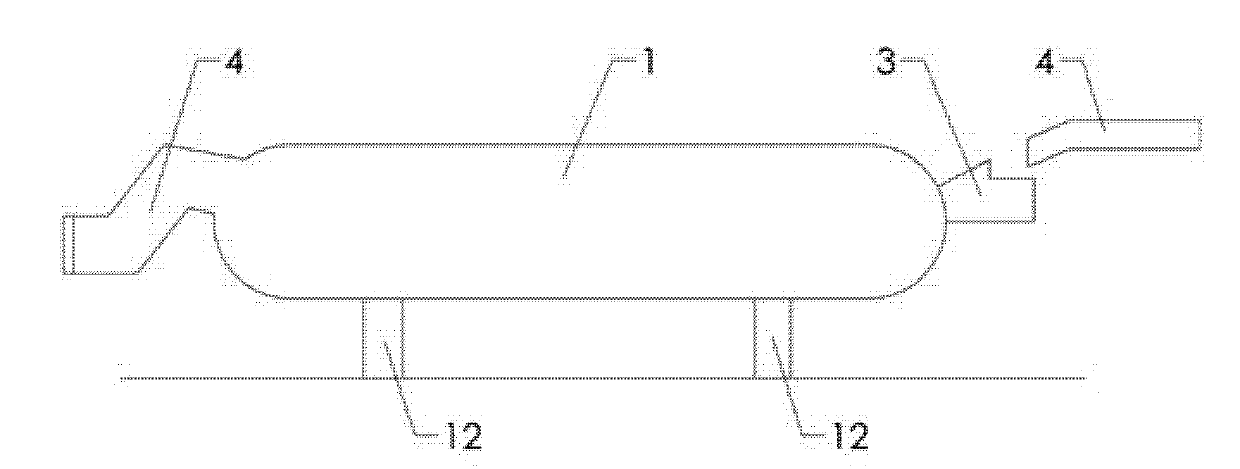

[0012] Such as figure 1 As shown: the anode refining furnace in this implementation includes a tiltable furnace body 1, and two jacks 12 are installed below the furnace body, and the tilting of the furnace body 1 is realized by lifting the two jacks 12.

[0013] The furnace body 1 is provided with a feed port 3 and a smoke exhaust port 4, and a connecting chute 4 is provided between the feed port 3 and the converting furnace.

[0014] The height difference between the feeding port and the copper outlet of the converting furnace is at least 1m, the smoke exhaust port is provided with an openable smoke exhaust cover, and the feeding port is provided with a camera.

[0015] When you want to add material, you can adjust the height of the jack to realize the tilting of the furnace body. At this time, the hot blister copper after blowing in the blowing furnace can be discharged from the copper discharge port of the blowing furnace, and flow into it from the feeding port of the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com