Vertical type full-suspension structure wind driven generator

A wind turbine, full suspension technology, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of complex structure, inconvenient maintenance, etc., and achieve improved bearing capacity, convenient installation and maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions and embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

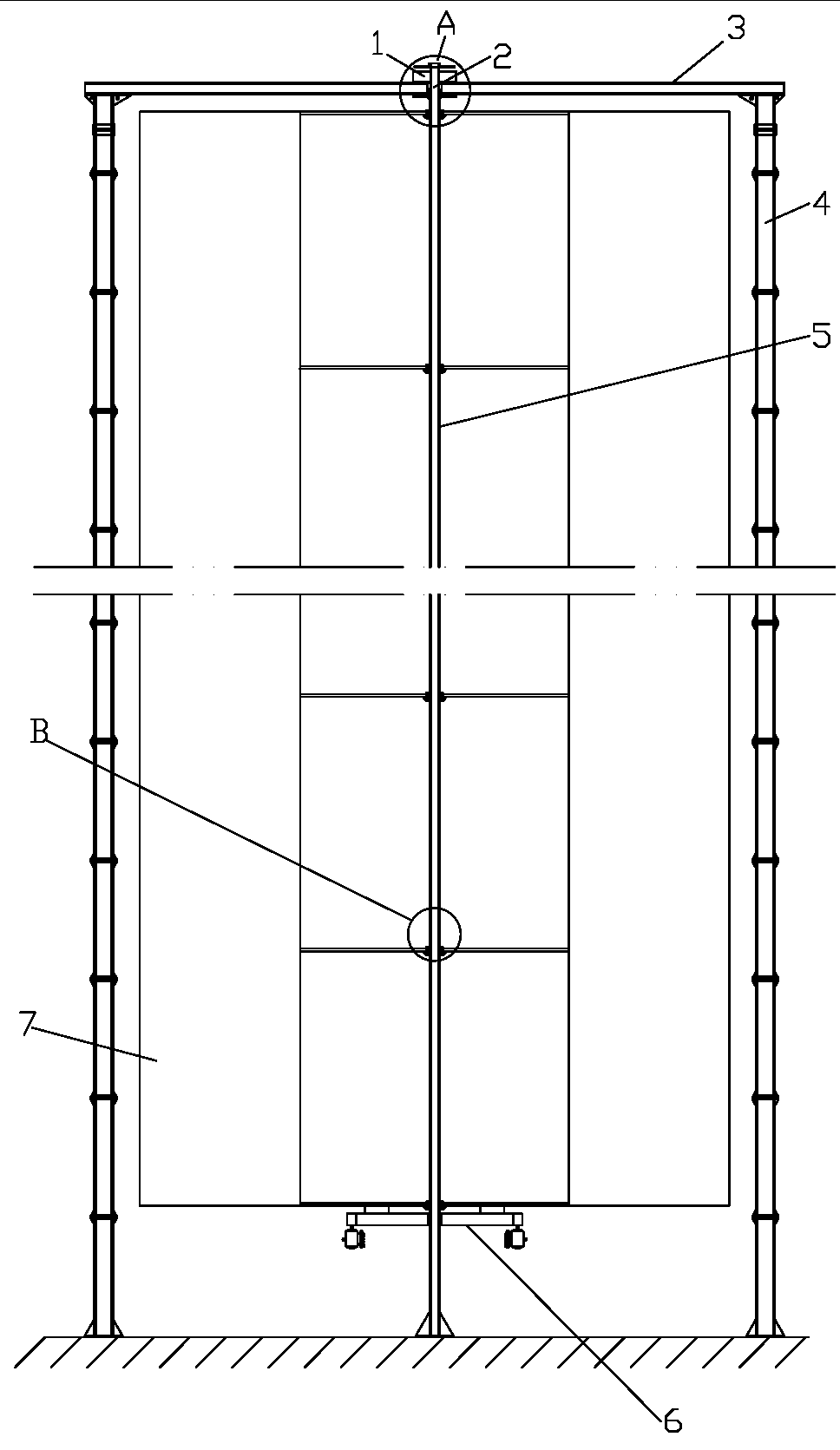

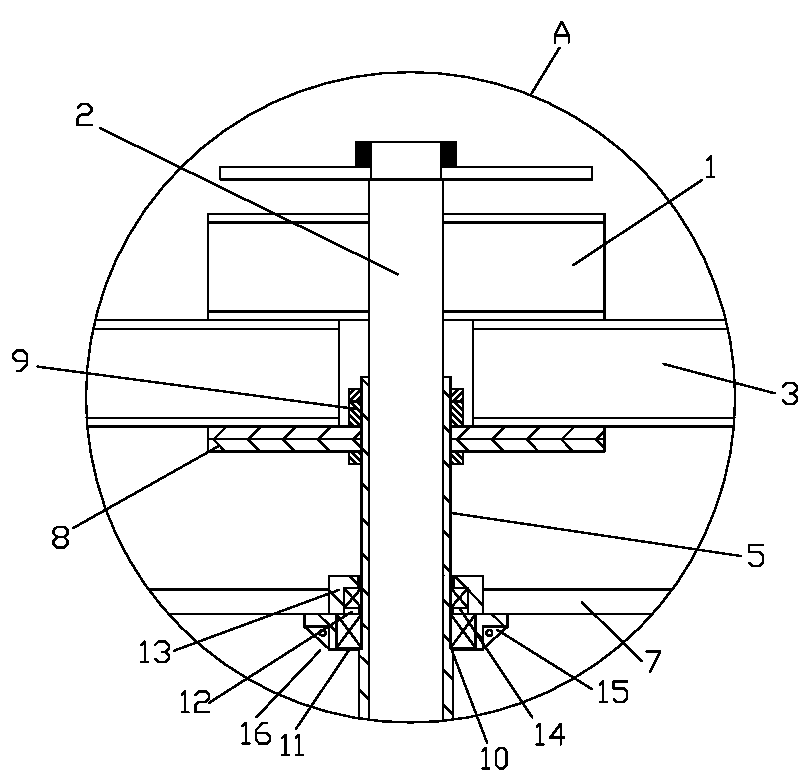

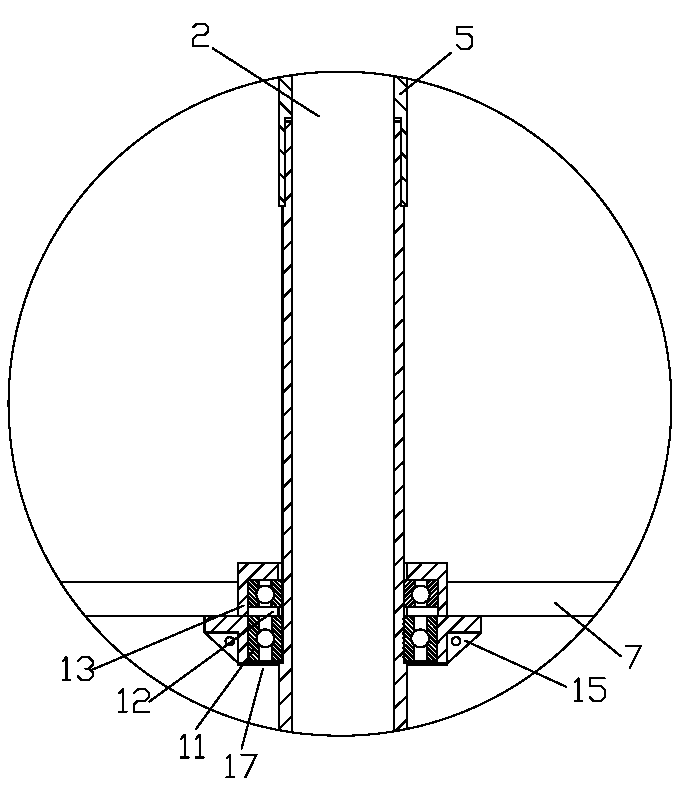

[0016] As shown in the figure, the vertical full-suspension structure wind power generator involved in the present invention includes a wind-driven device 7 and a power generation device 6, including a suspension column 4, a suspension beam 3, a full-suspension bearing seat 16, a center column 2 and a center Column cover 5, the four suspension columns 4 are evenly and vertically distributed around, the tops of the suspension columns 4 are fixedly connected with the suspension beams 3 respectively, the center shaft seat 1 and the center column 2 are arranged in the middle of the upper part of the suspension beams 3 The upper end of the upper end is installed in the central shaft seat 1, the central column cover 5 is set on the outside of the central column 2, and the upper end of the central column cover 5 is fixed on the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com