Discharge flue non-return device

A technology of non-return device and flue exhaust duct, which is applied in the field of oil fume exhaust devices, to achieve the effects of improving the closing and sealing performance, good exhaust effect, and improving the effect of non-return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

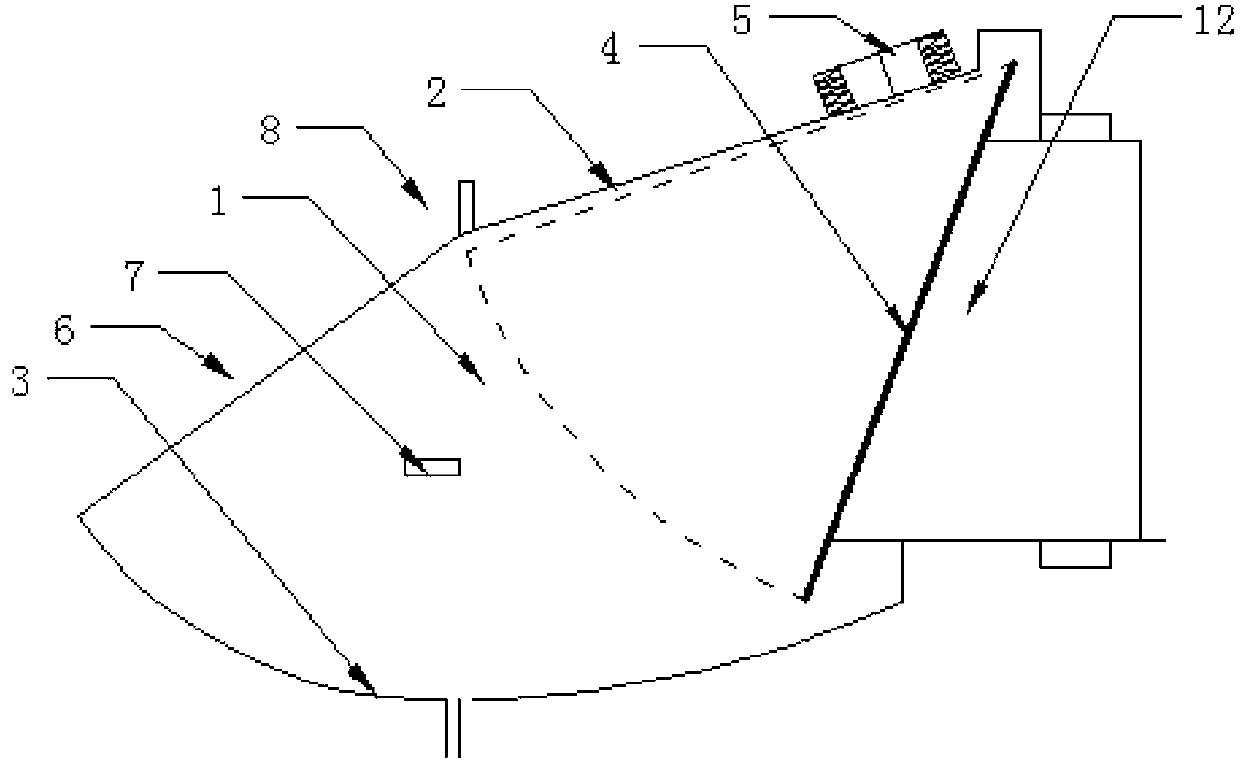

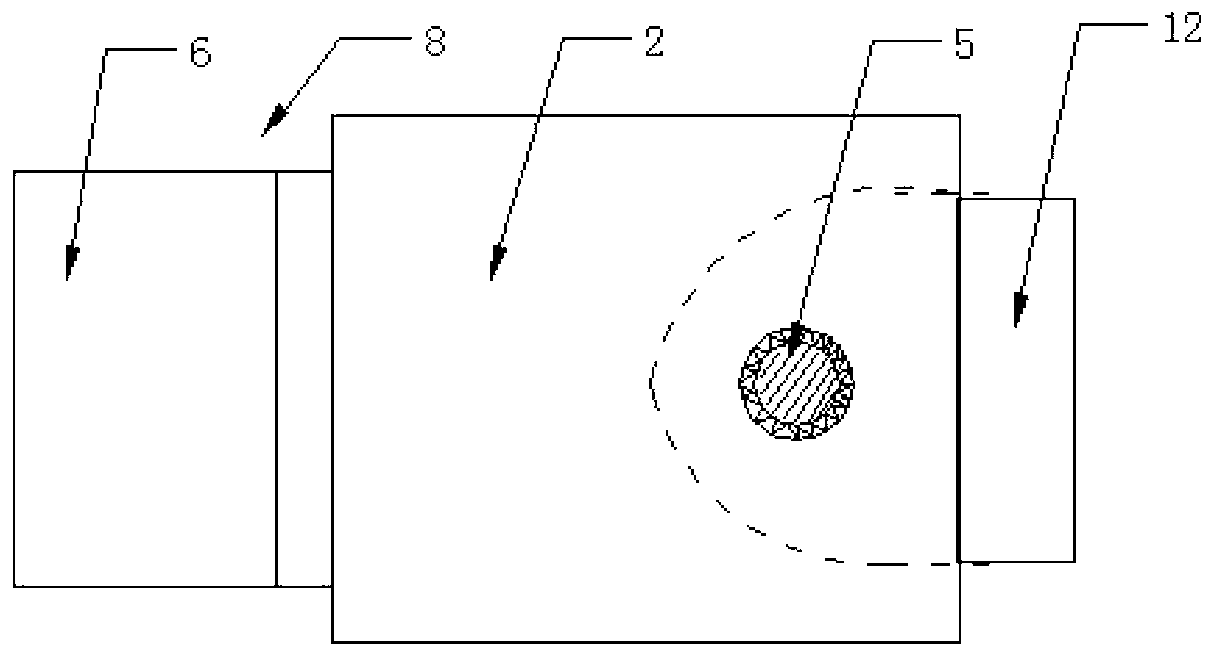

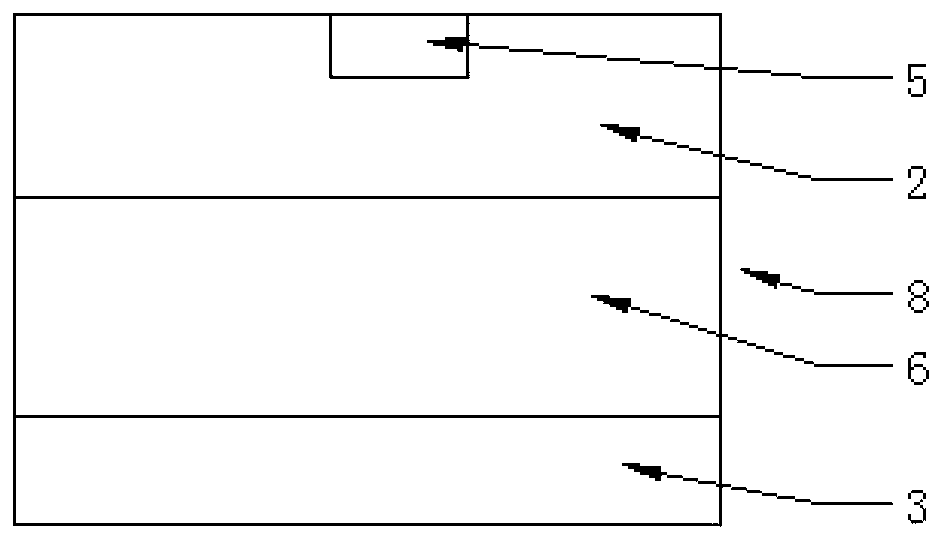

[0019] The present invention will be further described by embodiment now in conjunction with accompanying drawing. Such as Figure 1-3 As shown, the flue exhaust check device of this embodiment includes a discharge channel 1 with a square cross-sectional shape, which is formed by a piece of magnetically conductive material that is movably connected to the discharge channel 1 from the side of the discharge channel 1 through the connecting device. Non-return piece 4; the inlet side of the discharge channel 1 is connected with a coupling channel (pipe) 12 protruding (extending) toward the discharge channel or the direction of the exhaust channel corresponding to the non-return piece 4, the coupling channel (pipe) 12 (or its outlet) diameter or effective flow channel area is smaller than the corresponding diameter or effective working area of the non-return sheet 4 and the discharge channel 1, so that the non-return sheet 4 can completely cover the outlet of the coupling channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com