Axle box displacement transducer clamping device for bogie parameter test

A displacement sensor and parameter testing technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as troublesome adjustment of angle and position, weak contact, wear and tear, etc., to reduce debugging time, improve measurement accuracy, and secure installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

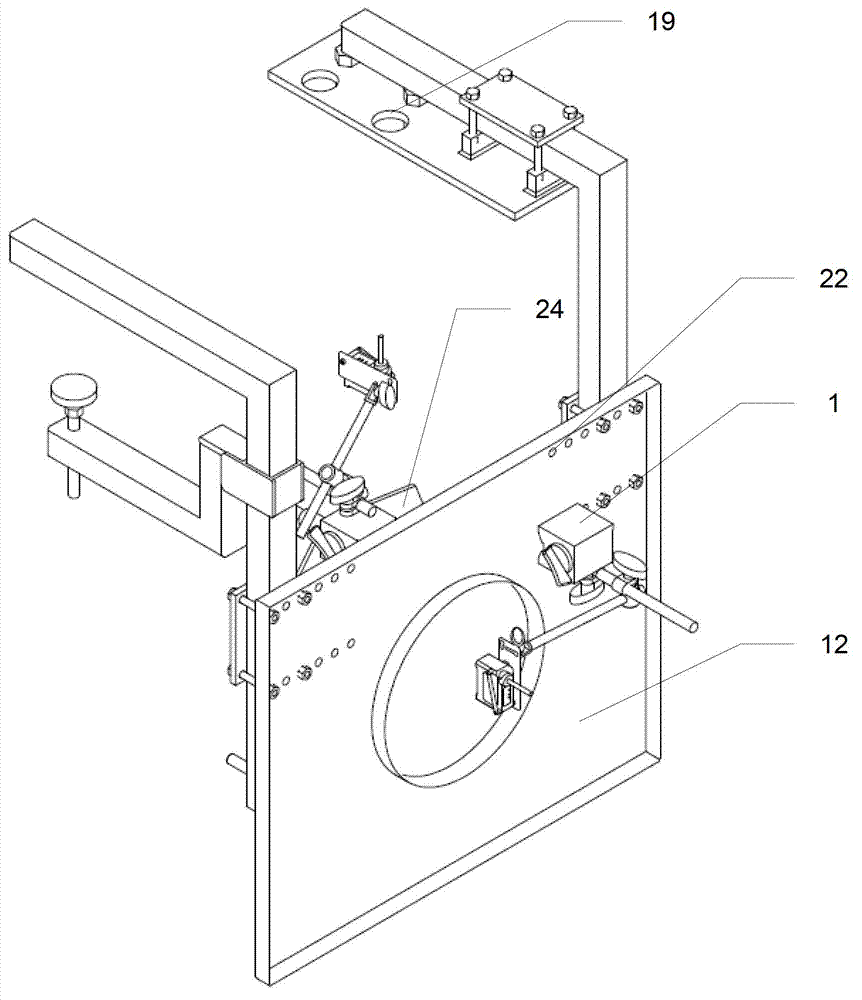

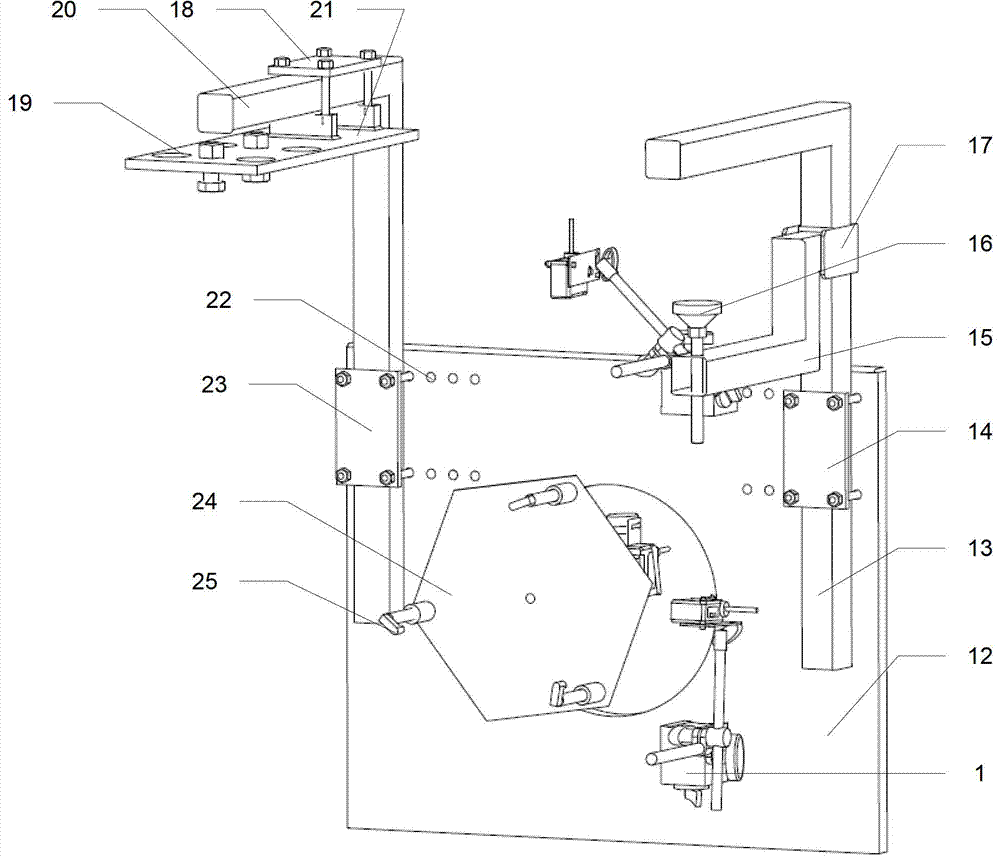

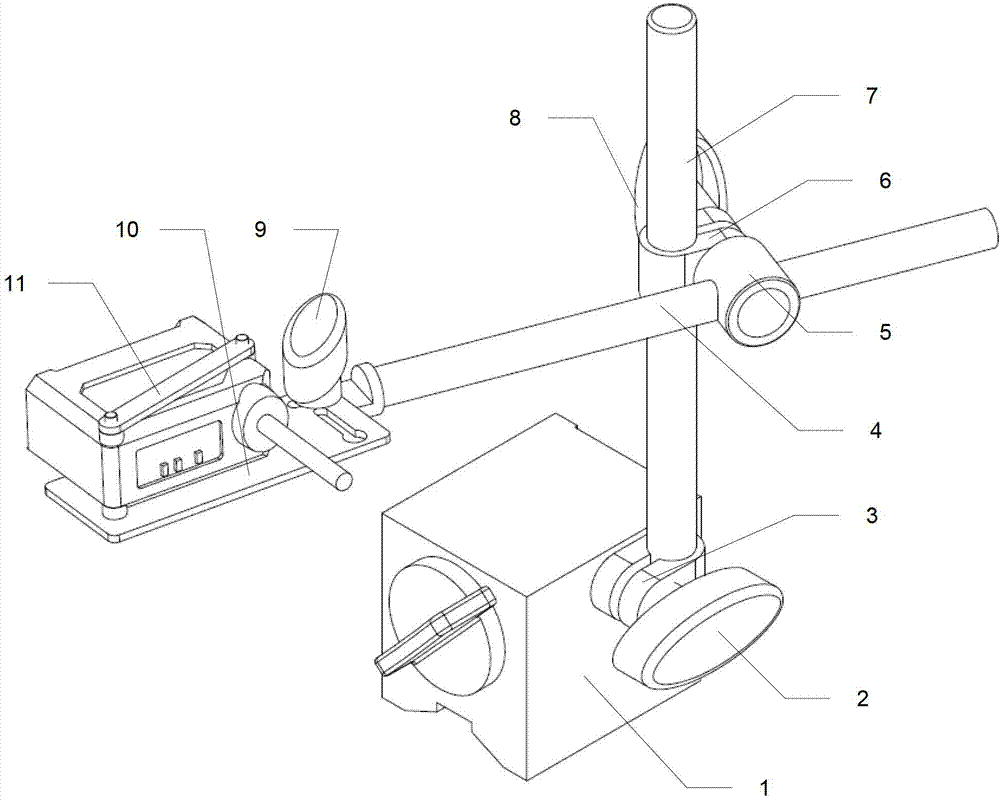

[0035] refer to figure 1 and figure 2 , the axlebox displacement sensor clamping device of a kind of bogie parameter test of the present invention comprises the axlebox magnetic table base adsorption plate assembly and 3 sets of axlebox magnetic table base assemblies with the same structure; when the measured bogie When the outermost end surface of the axle box is uneven, add the auxiliary clamp assembly of the axle box cover (sensor).

[0036] refer to Figure 4 , the said axle box magnetic table base adsorption plate assembly includes the axle box magnetic table base adsorption plate 12, the first L-shaped frame clamp assembly and the second L-shaped frame clamp assembly. The first L-shaped frame clamp assembly includes the first L-shaped frame clamp 13, the first L-shaped frame clamp pressure plate 14, the L-shaped frame clamp movable clamp 15, the L-shaped frame clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com