Method for measuring content of high magnesium in phosphate ore

A phosphate rock, high magnesium technology, applied in the field of detection, can solve the problems of poor accuracy of high magnesium results, cumbersome operation, strict requirements, etc., and achieve high accuracy and precision of results, low cost, accuracy and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

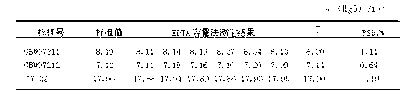

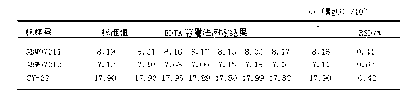

Embodiment 1

[0017] First prepare the main reagents:

[0018] ① 0.02mol / L disodium ethylenediaminetetraacetic acid (EDTA) standard solution: Weigh 8g of AR grade disodium ethylenediaminetetraacetic acid and dissolve it in water, dilute to 1000mL with water, and mix well. Calibration shall be carried out according to GB / T601. ②Sodium hydroxide solution: 200g / L, 20g / L; ethylene glycol diethyl ether diammonium tetraacetic acid (EGTA) solution: 70g / L; phenylglycolic acid solution: 50g / L; triethanolamine solution: 1+4; hydrochloric acid Solution: 1+9; ammonia solution: 2+3. ③Acid chrome blue K-naphthol green B indicator: Weigh 0.1g of AR grade acid chrome blue K, weigh 0.1g of AR grade naphthol green B, weigh 20g of AR grade chlorine Potassium chloride is placed in a mortar, thoroughly ground and mixed. ④ pH=10 ammonia water-ammonium chloride buffer solution: Weigh 67.5g of AR grade ammonium chloride, dissolve it in water, add 570mL of AR grade ammonia water, dilute to 1000 mL with water, an...

Embodiment 2

[0027] On the basis of the experimental method of embodiment 1,

[0028] Weigh about 0.15g sample, weigh to an accuracy of 0.0001g, place it in a 250mL beaker, add 25mL hydrochloric acid-nitric acid (aqua regia), gradually raise the temperature to 250°C, cover with a watch glass, and keep the temperature slightly boiling for 15min. After continuing to heat for 2.5 minutes, take down the glass beaker, rinse the watch glass and the inner wall of the beaker with 18mL water to cool, add 10mL phenylglycolic acid, stir well, add 12mL ethylene glycol diethyl ether diammonium tetraacetic acid (EGTA), add 35mL tris Ethanolamine, stir for a while, add 12mL dextrin, add two drops of malachite green indicator solution, neutralize with sodium hydroxide solution until the solution is colorless, then add 4mL, heat the solution to 85°C, and use Filter the funnel with a sponge ball filter pulp, wash the beaker and the precipitate with 55°C hot sodium hydroxide solution for 3 to 4 times; dissolve...

Embodiment 3

[0036] On the basis of the experimental method of embodiment 1,

[0037] Weigh about 0.2g sample, weigh to an accuracy of 0.0001g, place it in a 250mL beaker, add 25mL hydrochloric acid-nitric acid (aqua regia), gradually raise the temperature to 300°C, cover with a watch glass, and keep the temperature slightly boiling for 15min. After continuing to heat for 3 minutes, take off the glass beaker, rinse the watch glass and the inner wall of the beaker with 20mL water to cool, add 15mL phenylglycolic acid, after stirring well, add 14mL ethylene glycol diethyl ether diammonium tetraacetic acid (EGTA), add 40mL triethanolamine , stir for a while, add 15mL dextrin, add two drops of malachite green indicator solution, neutralize the solution with sodium hydroxide solution until the solution is colorless, then add 5mL in excess, heat the solution to 90°C, and use a pad to Filter the pulp through a funnel with a sponge ball, wash the beaker and the precipitate with 60°C hot sodium hyd...

PUM

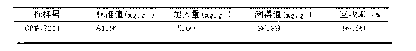

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap