Oilfield wastewater filtering device

A filter device and oilfield sewage technology, which is applied in the direction of filter separation, filter circuit, gravity filter, etc., can solve the problems that the filter efficiency needs to be improved, and achieve the effect of improving the filter efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

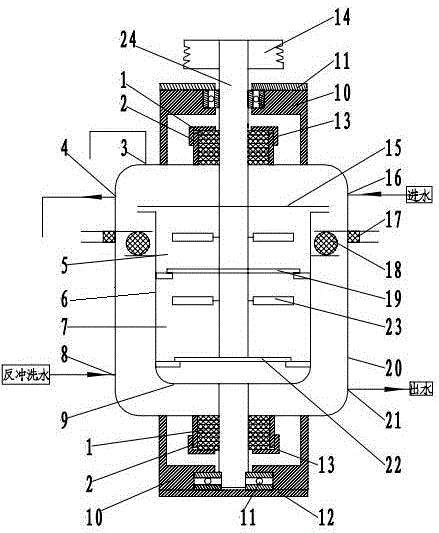

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Oilfield sewage filtering device of the present invention, as figure 1 Shown, comprise shell 20, washing bucket 6, transmission shaft 24 and washing bucket cover 15, transmission shaft is connected with motor by pulley 14. The sealing gasket 17 and the sealing ring 18 are used to seal between the shell 20 and the washing tub 6 . The washing bucket is installed inside the shell through the transmission shaft 24, and the shell is provided with a water inlet 16, a water outlet 21, a backwash inlet 8, an oil discharge port 3 and a sewage discharge port 4, and the sewage discharge port is used as a flushing water outlet at the same time. Backwash pump connection. The middle part of the washing tub is provided with an upper support plate 19 and a lower support plate 22, and the upper support plate and the lower support plate are equipped with a stainless steel fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com