Square emulsion preparing device

A technology of emulsion and compounder, which is applied in the direction of mixing methods, fluid mixers, mixer accessories, etc., can solve the problems of high machining accuracy requirements, unadjustable size, difficult to adjust the ratio of the rotary body, etc., to avoid fluid velocity If the difference is too large, the scope of application will be increased, and the processing and assembly will be convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

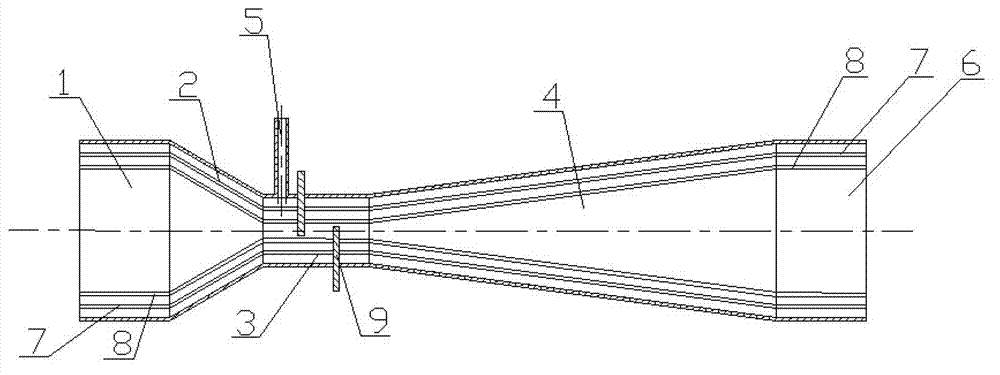

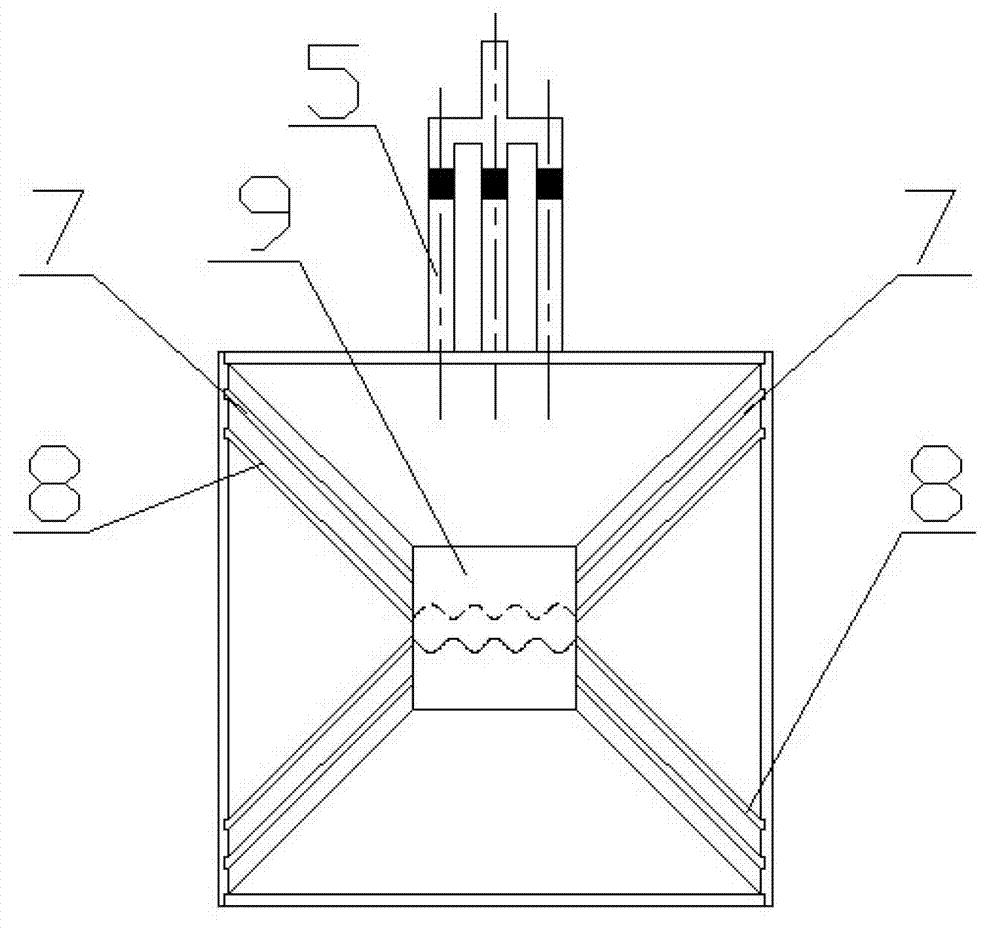

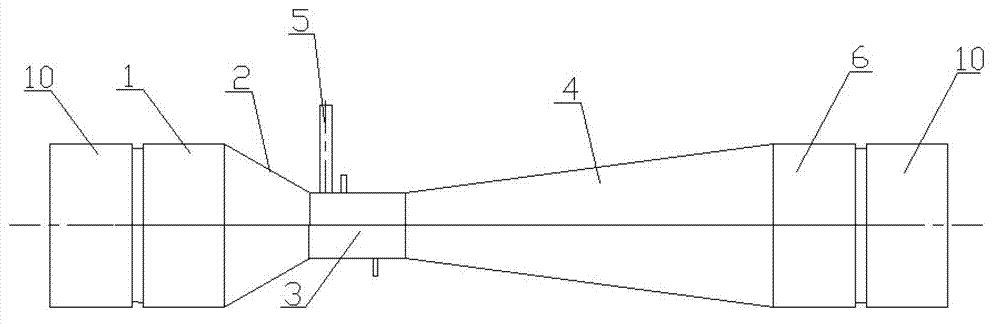

[0017] Such as figure 1 As shown, the present invention provides a square emulsion preparation device, comprising a main flow inflow pipe 1, a main flow constriction section 2, a main flow throat pipe 3, a main flow diffusion section 4 and a main flow outflow pipe 6 connected in sequence and arranged in the main flow throat The upper end of the pipe 3 and its connected side lead-in pipe 5, the main flow inflow pipe 1, the main throat pipe 3 and the main flow outflow pipe 6 are all square pipes, and the main flow constriction section 2 and main flow diffusion section 4 are quadrangular pyramid-like structures. The square emulsion preparation device of the present invention breaks through the design method of circular pipes in the past. The main flow inflow and outflow pipes and throat pipes are designed as square pipes, which is conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com