Progressive bending sheet metal

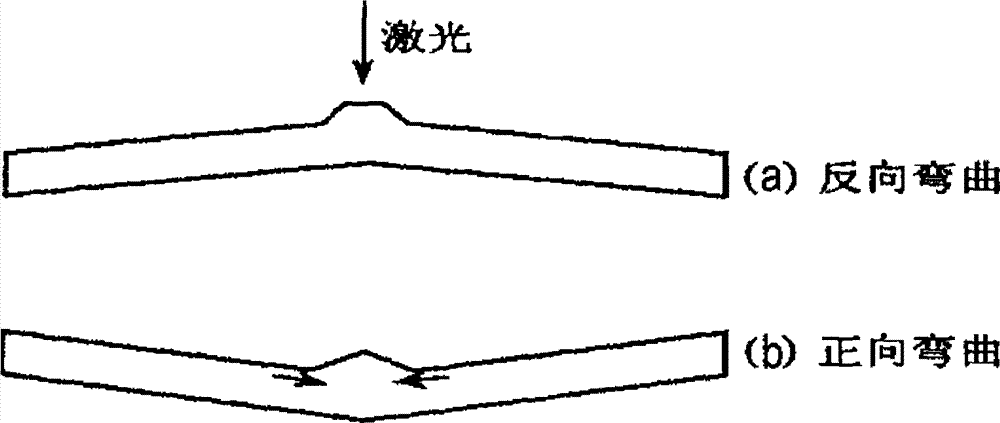

A sheet metal bending technology, which is applied in the field of continuous bending sheet metal, can solve problems such as difficult deformation, difficult realization, and complicated conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

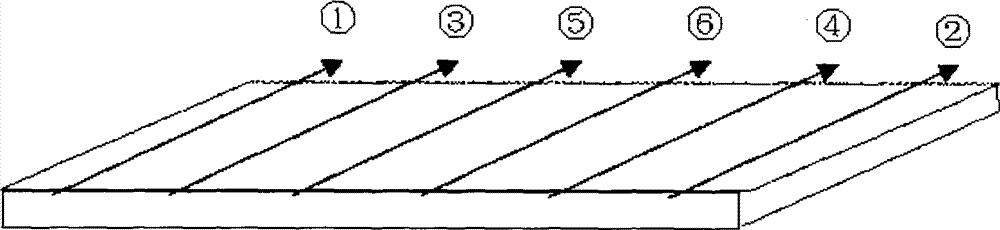

Embodiment

[0021] The OCr18Ni9 stainless steel sheet with a thickness of 0.15mm is used as the workpiece to be processed. The length of the sheet is 25mm (the actual part that needs to be processed is about 20mm) and the width is 5mm. The interval between passes was set to 2 mm, and thus a total of 10 passes were scanned, and each pass was reciprocally scanned 10 times. After the surface of the workpiece to be treated is ground with corundum sandpaper to remove foreign matter, the surface is pretreated with black paint, and then the thin plate is pressed between two glass plates. Set the diameter of the laser beam spot to 0.1mm, the power to 22W, and the scanning speed to 18mm, and proceed in the scanning order from both ends of the thin plate to the center. After scanning, let the processed workpiece stand still to cool naturally at room temperature, remove the fixture, take out the processed workpiece for measurement and verification, and the measured curvature of the thin plate is abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com