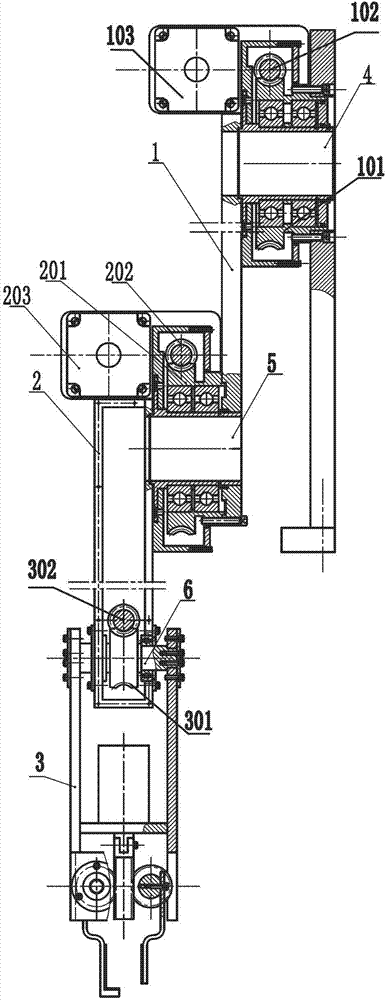

Screen printing plate conveying mechanical hand device of printing production line

A production line and manipulator technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as insufficient efficiency, high labor intensity, poor working environment, etc., and achieve the effect of fast action, reduced collision force, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

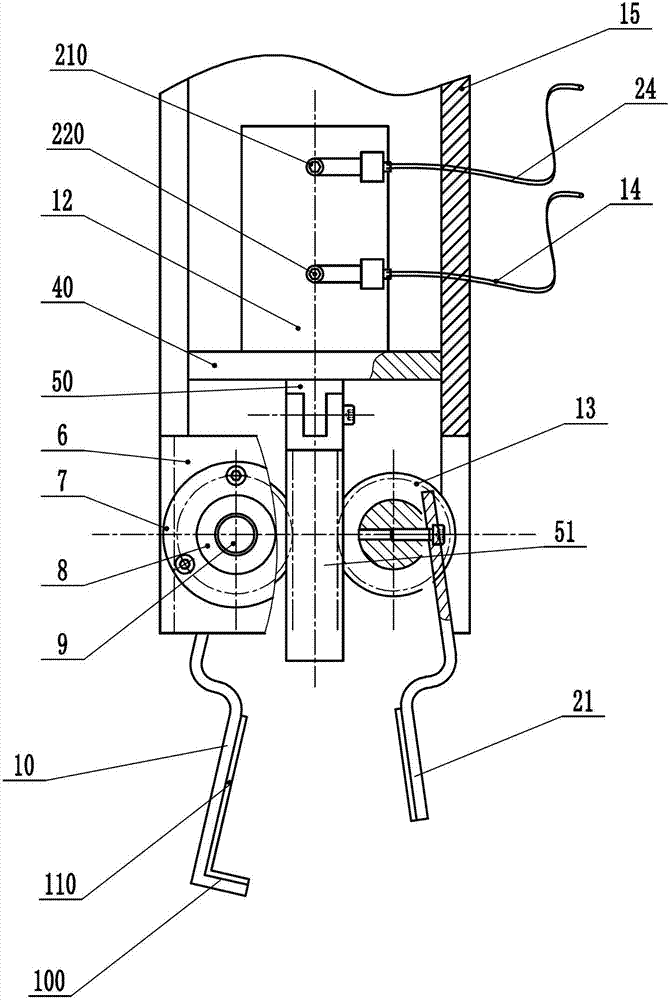

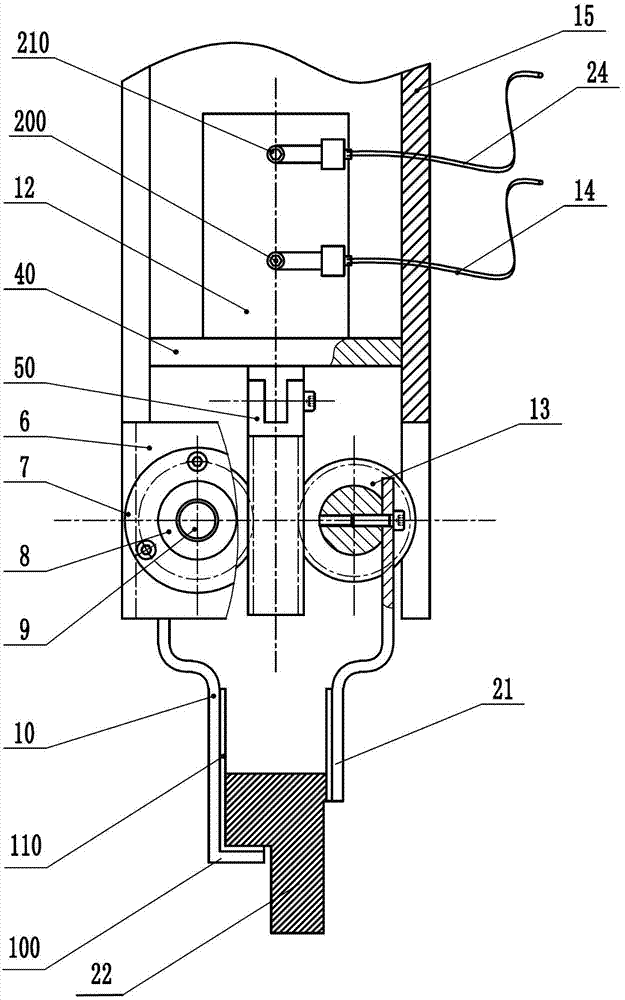

[0027] specific implementation plan

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The present invention comprises a pneumatic manipulator mechanism, a base 11, a three-joint manipulator slidably connected to one end of the base 11, and a base stop cylinder 70 connected to the other end of the base 11, and the base is fixed on the base stop cylinder 70 for the action stroke. On the guide rail slide block 91 of the linear guide rail 90 on the extension line, thereby can control the back and forth motion of base on the linear guide rail by controlling the action of stopper cylinder. Such as image 3 As shown, when the left end of the base stop cylinder 70 intake air, the cylinder rod 8 pushes the base 11 to translate a stroke of the base stop cylinder 70 to the right on the linear guide rail 90, and completes the extending action of the manipulator mechanism; After the action is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com