Pneumatic rope cutting machine

A cutting machine, pneumatic manipulator technology, applied in metal processing and other directions, can solve the problems of time-consuming and laborious, difficult to control the length, large quantity, etc., and achieve the effects of convenient adjustment, reasonable and practical structure, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

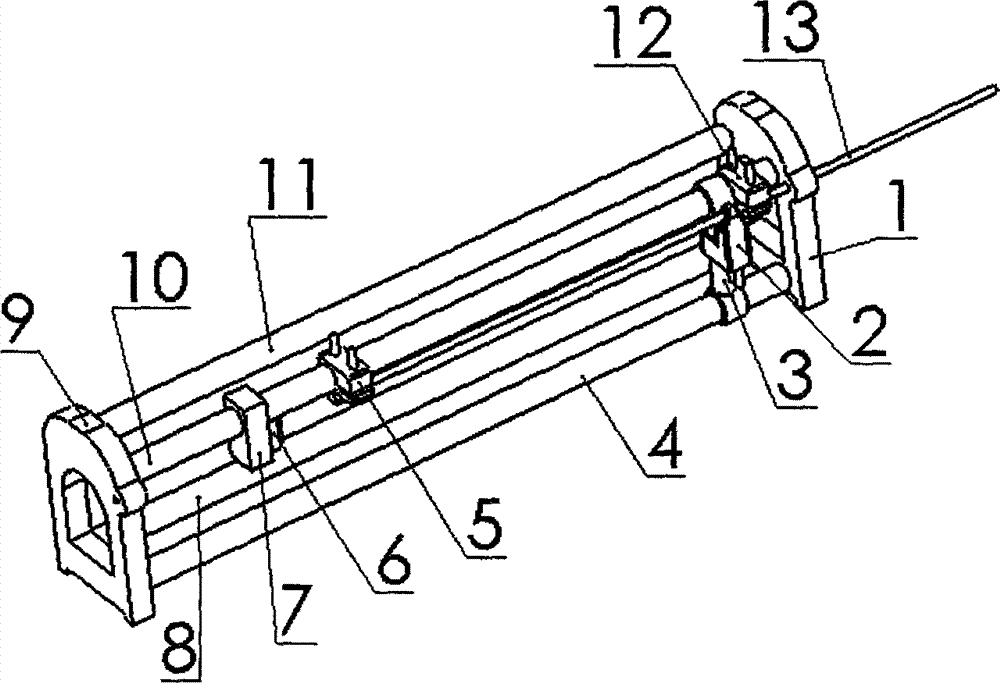

[0011] The pneumatic rope cutting machine is mainly composed of right end plate (1), pneumatic manipulator scissors (2), vertical rail (3), horizontal axis I (4), pneumatic manipulator I (5), travel switch (6), switch fixing plate (7), horizontal axis II (8), left end plate (9), horizontal rail (10), horizontal axis III (11), pneumatic manipulator II (12), gas circuit, and control system form. The right end plate (1), the left end plate (9), the transverse axis I (4), the transverse axis II (8), the transverse rail (10), the transverse axis III (11) Make up the rack. The two ends of the vertical rail (3) are respectively connected with the horizontal axis I (4) and the horizontal rail (10), and the pneumatic manipulator scissors (2) can be placed on the vertical rail (3) through an air circuit. Move up and down and can cut the rope. The switch fixing plate (7) is connected with the horizontal rail (4), and the travel switch (6) is mounted on the switch fixing plate (7). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com