Typhoon-resistant drilling riser buoyancy tank device

A riser and typhoon prevention technology, applied in the direction of floating buildings, etc., can solve the problems of no structural design scheme, immature technology of typhoon-proof drilling riser system, etc., to improve safety and reliability, easy installation, and prevent buoyancy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

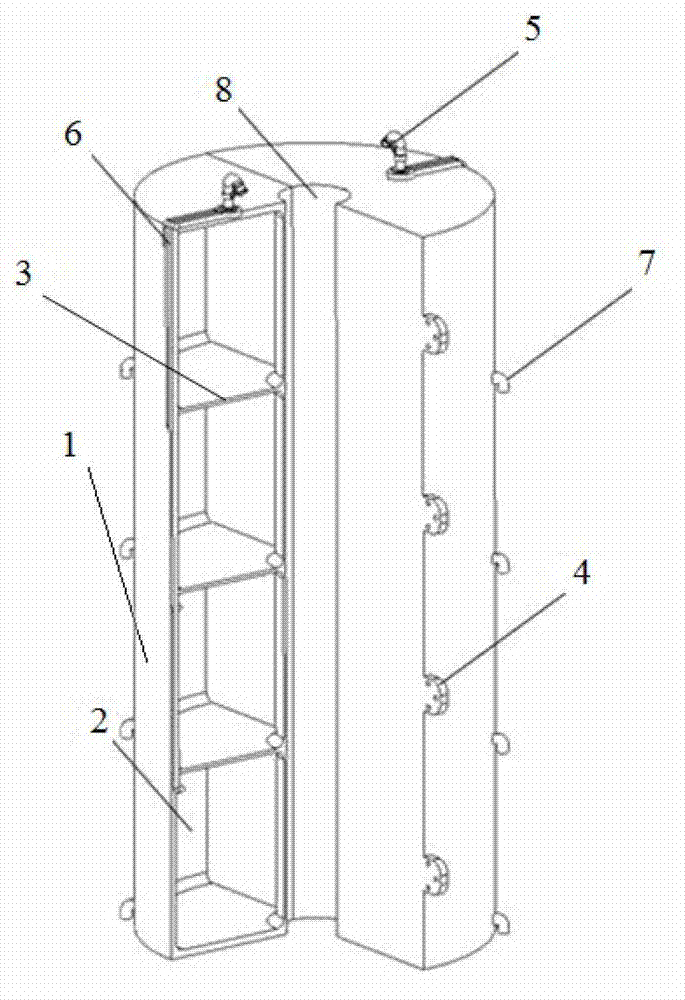

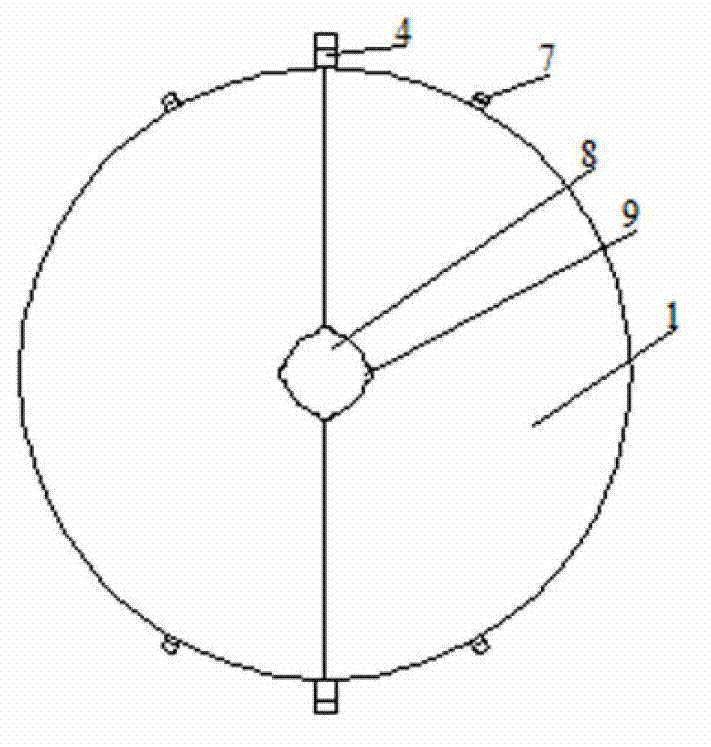

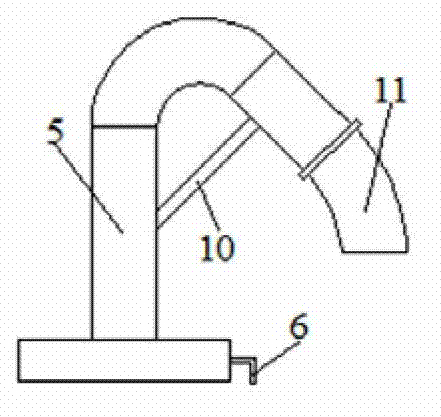

[0020] like figure 1 As shown, the anti-typhoon drilling riser buoyancy tank device includes two buoyancy tank units 1, the buoyancy tank unit 1 is a semi-cylindrical body, the buoyancy tank unit 1 is composed of four independent buoyancy tank chambers 2, and each chamber is composed of The plate 3 is separated to prevent the failure of individual chambers from affecting the working performance of other chambers; there are four flanges 4 on both sides of the buoyancy tank unit 1, and the two buoyancy tank units 1 can be connected into one through flanges 4 and bolts Complete buoyancy tank device; each buoyancy tank unit 1 is provided with a gooseneck 5 at the top, the lower end of the gooseneck 5 is connected with the air intake pipe 6 of the buoyancy tank chamber 2, and a drain pipe 7 is provided at the bottom of each buoyancy tank chamber 2 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com