Technology process for recovering spandex DMAC (Dimethylacetamide) solvent

A process method and solvent technology are applied in the field of spandex DMAC solvent recovery, which can solve the problems of low yield and large loss, and achieve the effects of reducing production costs, improving social benefits, and saving energy consumption.

Inactive Publication Date: 2013-05-22

TIANJIN PULAI CHEM TECH

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main disadvantage of this process is: as the main solvent DMAC in the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

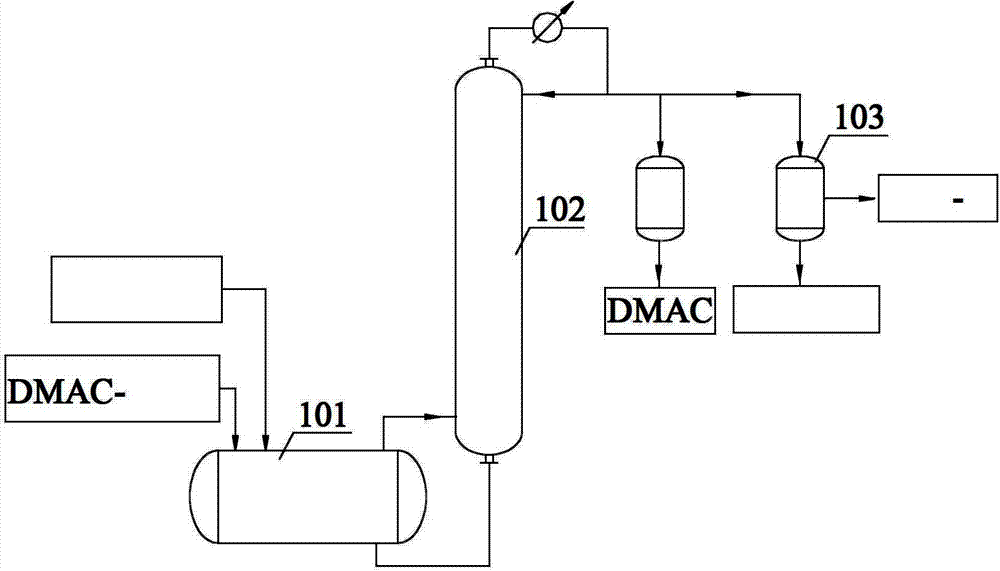

The invention relates to a technology process for recovering a spandex DMAC (Dimethylacetamide) solvent, and in particular relates to a technology process in which the tetrachloroethylene is adopted and used as an azeotrope agent to carry out azeotropic distillation and separation to DMAC and acetic acid. The technology process comprises the following steps: adding tetrachloroethylene and a DMAC-acetic acid mixed solvent to an azeotropic distillation tower together, thus obtaining an acetic acid-tetrachloroethylene azeotrope from the top of the azeotropic distillation tower; condensing and cooling; reflowing part of the azeotrope to the azeotropic distillation tower; and transferring the other part of the azeotrope to a split-phase tank; adding water to the split-phase tank; stirring; standing for layering, wherein the tetrachloroethylene is generated at the lower layer and can be recycled, the acetic acid-water solution at the upper layer can be rectified and separated to obtain an acetic acid product; and continuously rectifying after the tetrachloroethylene and the acetic acid in the azeotropic distillation tower are completely discharged, thus obtaining the qualified DMAC product from the top of the azeotropic distillation tower. By adopting the technology process, the DMAC and the acetic acid can be completely separated, so that the pollution of direct drainage to the environment can be avoided, the production cost is reduced, and the social benefit is increased.

Description

technical field [0001] The invention relates to a process method of solvent recovery, in particular to a process method of spandex DMAC solvent recovery, which uses azeotropic distillation to separate DMAC (N,N-dimethylacetamide) and acetic acid mixed solvents in the spandex industry. Background technique [0002] N,N-Dimethylacetamide, referred to as DMAC, is an important organic chemical raw material, a pharmaceutical intermediate, and a solvent with excellent performance. A large amount of mixed solution of DMAC and acetic acid is produced in the production of spandex. How to recover DMAC and acetic acid economically and effectively is very important to improve the overall economic and social benefits of the enterprise and reduce pollution emissions. [0003] Since DMAC and acetic acid can form the highest azeotrope, and the azeotropic composition is DMAC: acetic acid = 76:24, it is impossible to completely separate the two through ordinary distillation. [0004] The con...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C233/05C07C231/24C07C53/08C07C51/46

Inventor 张倩瑜徐仁萍刘翠茹钟宏伟

Owner TIANJIN PULAI CHEM TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com