Pile position deviation real time detecting device

A real-time detection and deviation technology, which is applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problems of difficult to find deviation value, high detection cost, and difficult to obtain deviation direction, so as to facilitate the inspection personnel and the inspection. The effect of wide range and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

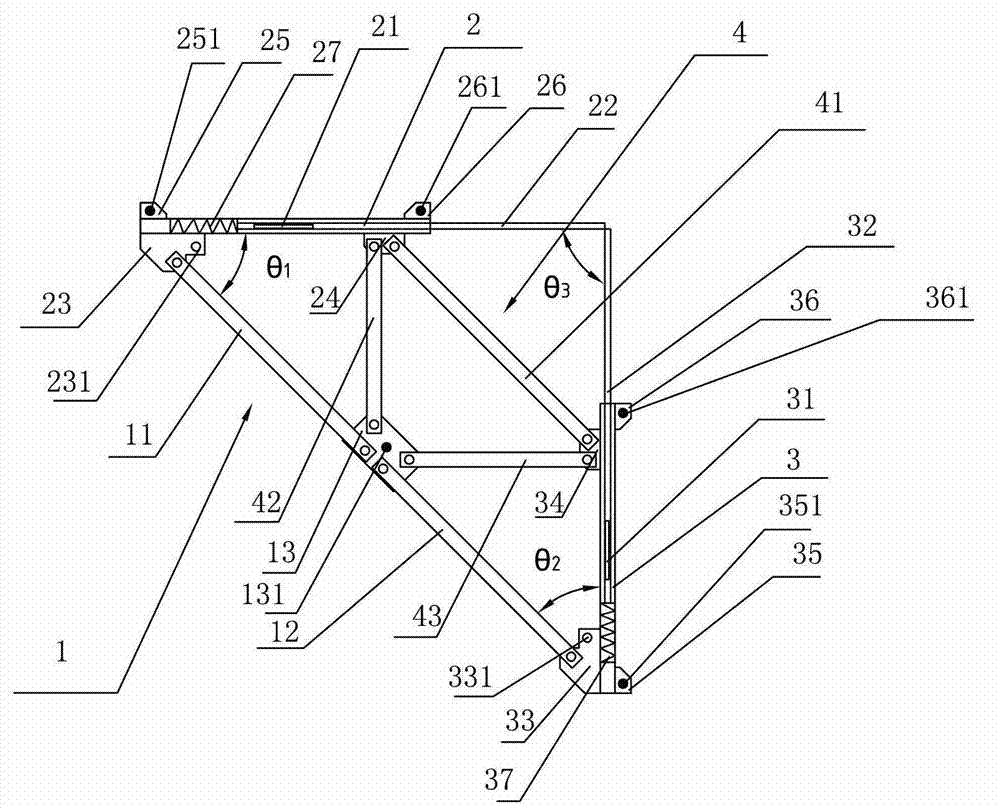

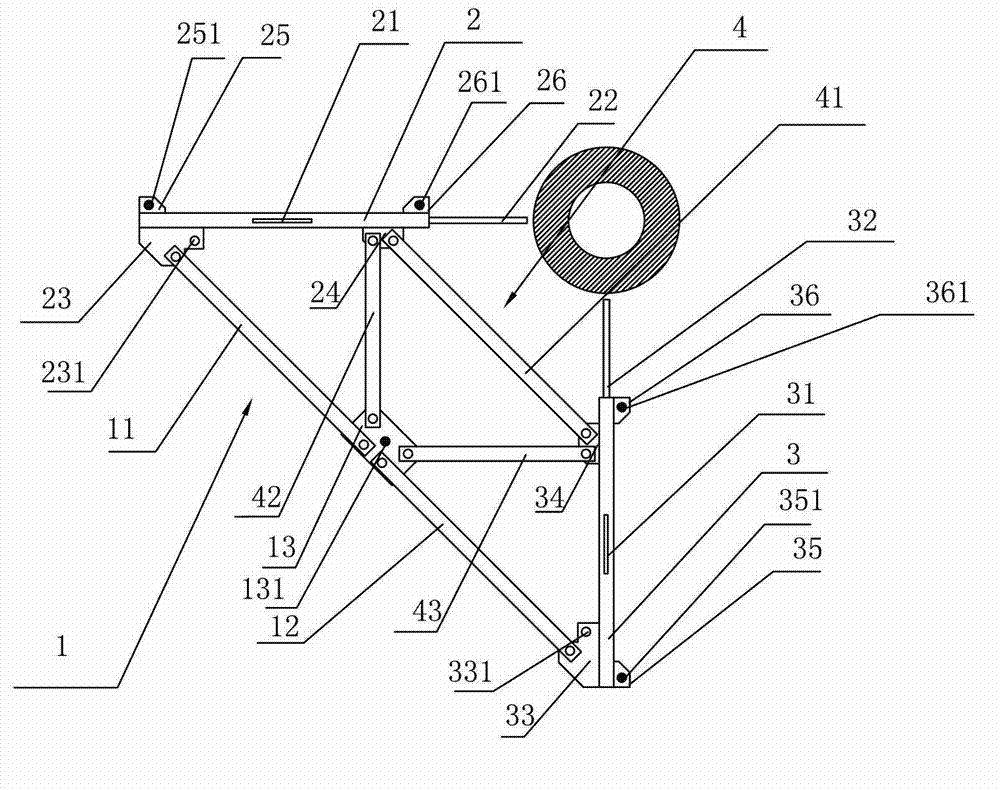

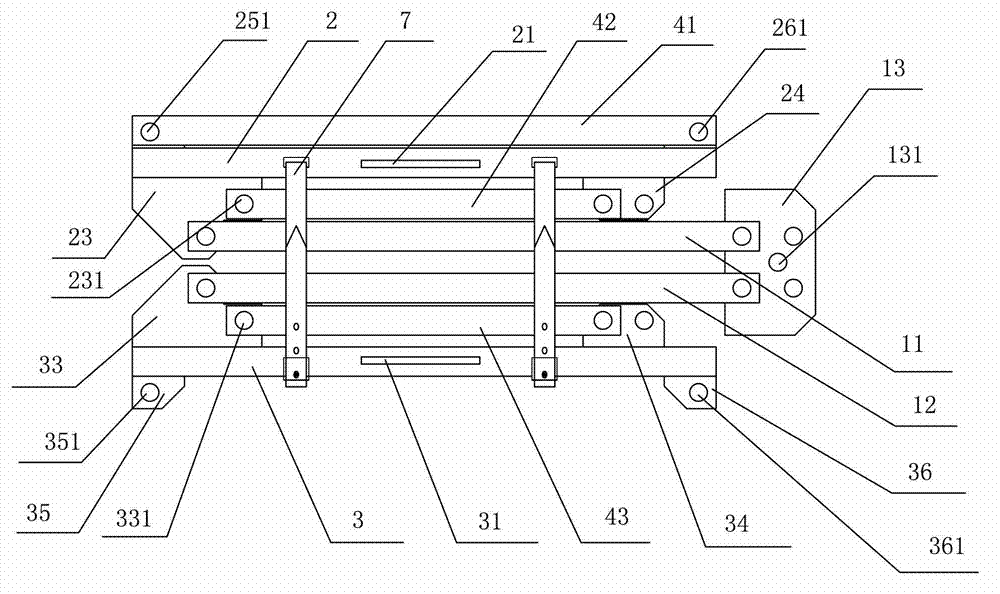

[0023] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0024] As shown in the figure, a real-time detection device for pile position deviation includes a main support rod 1, a first detection rod 2 and a second detection rod 3, the first detection rod 2 and the second detection rod 3 have the same length, and the first detection rod 2 is made of a metal square tube, the first detection rod 2 is provided with a first level tube 21 and a first sliding scale 22 that can be extended and retracted along the axial direction of the first detection rod 2, and the first sliding scale 22 is installed on the metal square tube. In the tube core, a first spring 27 is arranged between the first detection rod 2 and the first sliding scale 22, the second detection rod 3 is made of a metal square tube, and a second level tube 31 is arranged on the second detection rod 3 and a second sliding scale 32 that can be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com