Mass flow piezoelectric straight moving hydraulic reliever

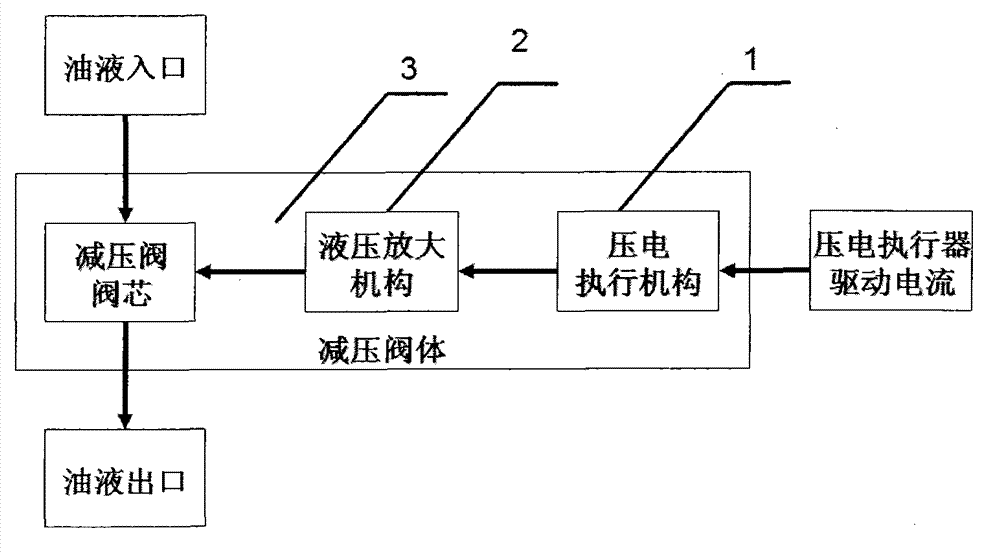

A technology of decompression device and high flow rate, applied in transmission control, components with teeth, belts/chains/gears, etc., it can solve the problem of affecting decompression accuracy, output flow and high-speed response, which cannot satisfy the shifting control hydraulic system. , structural limitations and other issues, to achieve the effect of improving the decompression speed and voltage stabilization accuracy, ingenious design, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

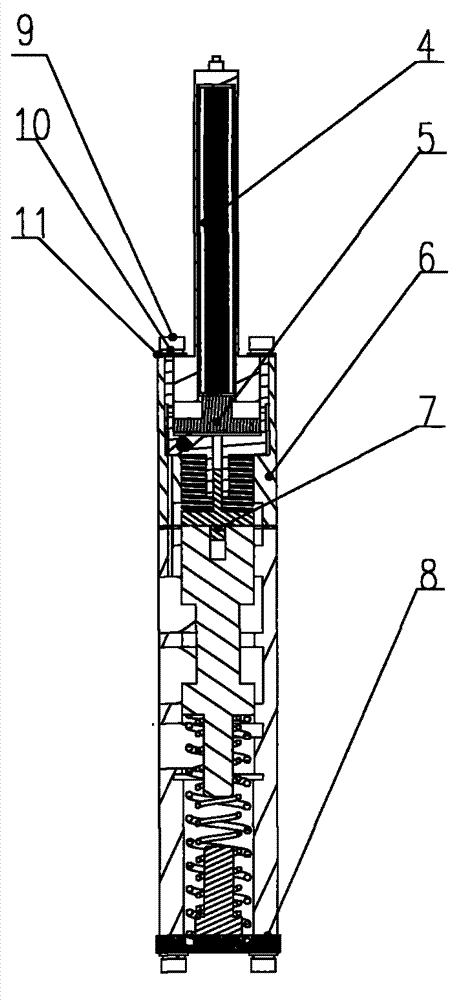

[0017] Such as figure 2 As shown, the large-flow piezoelectric direct-acting hydraulic decompression device of the present invention includes a piezoelectric actuator 4, a hydraulic amplifying mechanism 5 and a decompression valve body. The pressure reducing valve body includes an upper pressure reducing valve body 6 and a lower pressure reducing valve body 8. The upper pressure reducing valve body 6 is equipped with a piezoelectric actuator 4 and a hydraulic amplifying mechanism 5 sequentially from top to bottom. The upper pressure reducing valve body 6 It is fixedly connected with the lower pressure reducing valve body 8 through the connecting bolt 9, and a spring washer 10 and a flat pad 11 are installed at the joint of the connecting bolt 9, and paper is used between the joint surface of the upper pressure reducing valve body 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com